Friction-stir welding method of ferrite/austenite dissimilar steel

A technology of friction stir welding and friction stir, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve problems such as slag inclusion, thermal cracks, etc., and achieve small post-weld stress, good performance, and heat input little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

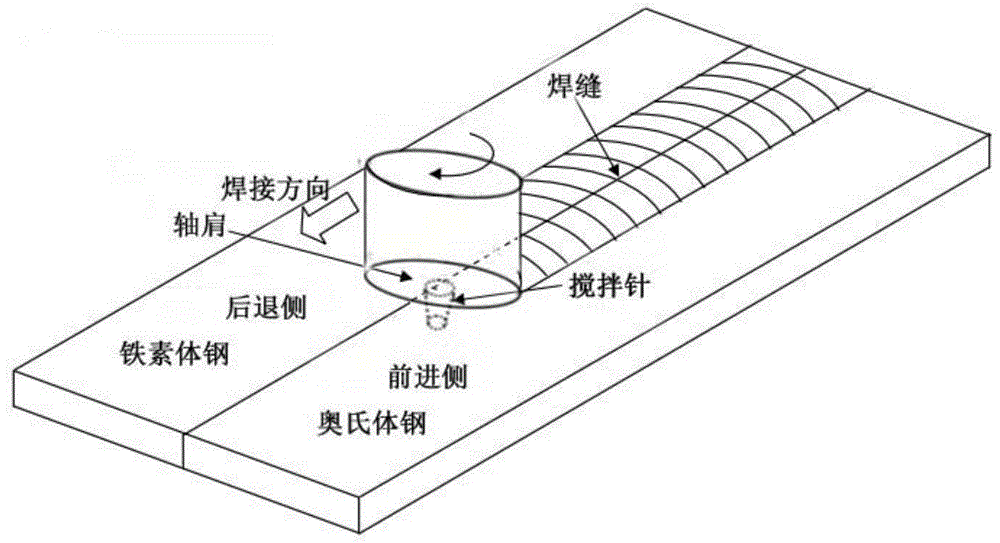

[0020] use figure 1 The steps shown are for friction stir welding of ferritic / austenitic dissimilar steels. There is no need to preheat the steel plate to be welded before welding, and no heat treatment is required during the welding process; the thickness of the selected ferritic steel plate is 1.5mm , the thickness of the austenitic steel plate is 1.6mm; the diameter of the shaft shoulder is 10mm, the diameter of the end of the stirring needle is 2mm, the diameter of the root is 6mm, and the length is 1.3mm; the tapered stirring needle with a flat end face is used, and the austenitic steel is used as the forward side. The ferritic steel is used as the retreat side, the stirring head is located on the side of the austenitic steel, the distance between the center of the stirring head and the butt joint surface, that is, the offset is 0mm, the inclination of the stirring head is 2.5°, and the welding is carried out along the direction of the weld; press down The amount is 0.1mm...

Embodiment 2

[0025] use figure 1 The steps shown are for friction stir welding of ferritic / austenitic dissimilar steels. Preheating of the steel plates to be welded is not required before welding, and no heat treatment is required during welding. The thickness of the selected ferritic steel plates is 2 mm. The thickness of the austenitic steel plate is 2.2mm; the diameter of the shoulder is 12mm, the diameter of the tip of the stirring pin is 4mm, the diameter of the root is 8mm, and the length is 1.8mm; The element steel is used as the retreat side, the stirring head is located on the side of the austenitic steel, the distance between the center of the stirring head and the butt joint surface is 0.2mm, the inclination of the stirring head is 1.5°, and the welding is carried out along the direction of the weld; press down The amount is 0.2mm; the travel speed of the stirring head is 50mm / min, and the rotation speed is 500rpm; after the welding is completed, the fixing device is loosened af...

Embodiment 3

[0027] use figure 1 The steps shown are for friction stir welding of ferritic / austenitic dissimilar steels. There is no need to preheat the steel plate to be welded before welding, and no heat treatment is required during the welding process; the thickness of the selected ferritic steel plate is 3.8mm , the thickness of the austenitic steel plate is 3.9mm; the diameter of the shaft shoulder is 18mm, the diameter of the end of the stirring needle is 5mm, the diameter of the root is 9mm, and the length is 3.6mm; the flat-end tapered stirring needle is used, and the austenitic steel is used as the forward side. The ferritic steel is used as the retreat side, the stirring head is located on the side of the austenitic steel, the distance between the center of the stirring head and the butt joint surface is 0.3mm, the inclination angle of the stirring head is 3°, and the welding is carried out along the direction of the weld; The pressure is 0.3mm; the travel speed of the stirring h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com