Sulphoaluminate cement composition, and preparation method and application thereof

A technology of sulfoaluminate cement and composition, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of slow cement hardening, high molding breakage rate, low production efficiency, etc., and achieves reduction of water consumption and strong structural strength. , the effect of sufficient response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

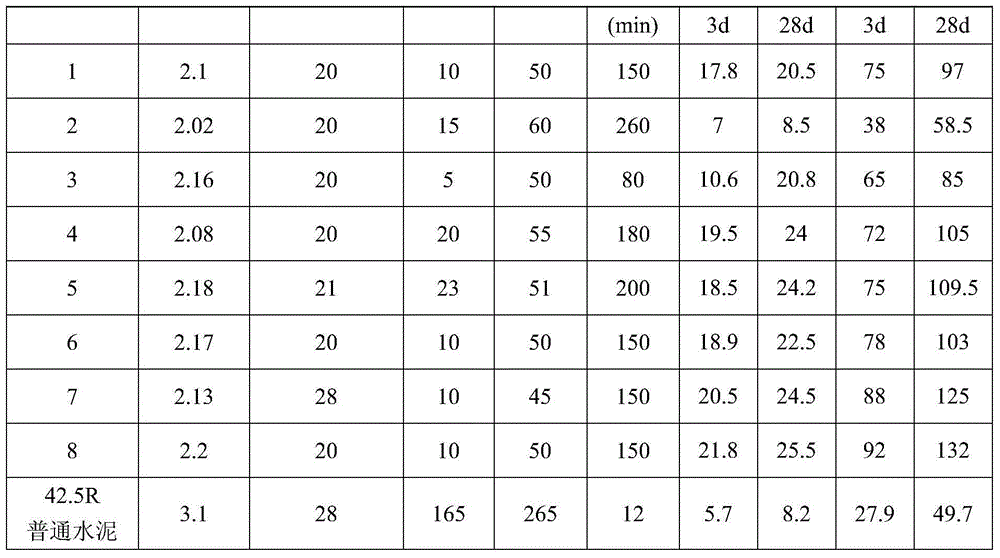

Embodiment 1

[0031] A sulphoaluminate cement composition provided in an embodiment of the present invention includes, in parts by weight, 100 parts of sulphoaluminate cement, 120 parts of quartz sand, 0.8 parts of short fibers, 1 part of sawdust, 1 part of nanometer Silica, 3 parts of water retaining agent, 1 part of cement quick-drying agent and 3 parts of polymer cement water reducer.

[0032] Among them, the short fiber is glass short fiber with a length of 5-8 mm. The nano-silica can be commercially available products, such as the nano-silica of Xuancheng Jingrui New Material Co., Ltd. The water retaining agent adopts hydroxypropyl methylcellulose. The cement quick-drying agent adopts commercially available GRC quick-hardening agent. The polymer cement water reducer adopts the commercially available β-naphthalene xanthate methylaldehyde polymer water reducer.

[0033] The sulphoaluminate cement composition of the present invention can harden quickly through the proportioning of raw ...

Embodiment 2

[0037] A sulfoaluminate cement composition provided in an embodiment of the present invention comprises, in parts by weight, 100 parts of sulfoaluminate cement, 100 parts of quartz sand, 0.5 parts of short fibers, 0.5 parts of sawdust, 0.2 parts of nanometer Silicon oxide, 2 parts of water retaining agent, 0.3 part of cement quick-drying agent and 0.5 part of polymer cement water reducer. Wherein, the short fiber is glass short fiber with a length of 2-10 mm. The nano-silica can be commercially available products, such as the nano-silica of Xuancheng Jingrui New Material Co., Ltd. The water retaining agent adopts hydroxypropyl methylcellulose. The cement quick-drying agent adopts commercially available GRC quick-hardening agent. The polymer cement water reducer is commercially available β-naphthalene xanthate methylaldehyde polymer water reducer or sodium lignosulfonate.

[0038] The preparation method of the sulphoaluminate cement composition in Example 2 of the present in...

Embodiment 3

[0040] A sulphoaluminate cement composition provided in an embodiment of the present invention includes, in parts by weight, 100 parts of sulphoaluminate cement, 150 parts of quartz sand, 1 part of short fiber, 2 parts of sawdust, 2 parts of nanometer Silica, 5 parts of water retaining agent, 2 parts of cement quick-drying agent and 5 parts of polymer cement water reducer. Wherein, the short fiber is glass short fiber with a length of 2-10 mm. The nano-silica can be commercially available products, such as the nano-silica of Xuancheng Jingrui New Material Co., Ltd. The water retaining agent adopts hydroxypropyl methylcellulose. The cement quick-drying agent adopts commercially available GRC quick-hardening agent. The polymer cement water reducer is commercially available β-naphthalene xanthate methylaldehyde polymer water reducer or sodium lignosulfonate.

[0041] The preparation method of the sulphoaluminate cement composition in Example 3 of the present invention is as de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com