Post-tensioned pre-stressing pipeline grouting agent

A technology of prestressed pipeline and grouting agent, which is applied in the field of building materials to ensure compactness, avoid settlement and cracking, and improve impermeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

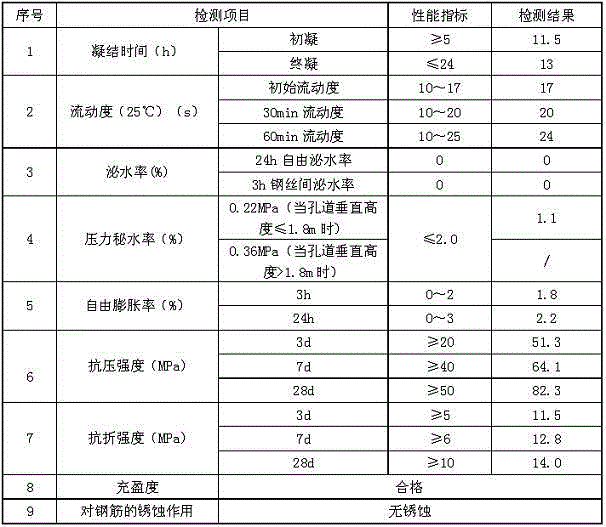

Embodiment 1

[0032] Example 1 A post-tensioning prestressed pipeline grouting agent, the grouting agent is obtained by stirring the raw material components in the following weight percentage (kg) at a speed of not less than 1000r / min: water-reducing component 4.7%, plasticity Expansion component 0.3%, mid-late expansion component 28.2%, stabilizing component 0.1%, retarding component 0.4%, defoaming component 0.3%, ultrafine active mineral admixture 47.1%; sulphoaluminate cement 18.9% %.

[0033] in:

[0034] The water-reducing component refers to the powdered polycarboxylate water-reducing agent with a water-reducing rate ≥ 20%, and the manufacturer is Suzhou Fuke New Building Materials Co., Ltd.

[0035] The plastic expansion component refers to the plastic expansion agent, and the manufacturer is Beijing Wanji Jianye Co., Ltd.

[0036] The middle and later expansion components refer to UEA expansion agent, and the manufacturer is Lanzhou Tianchuang Keyuan New Building Materials Co...

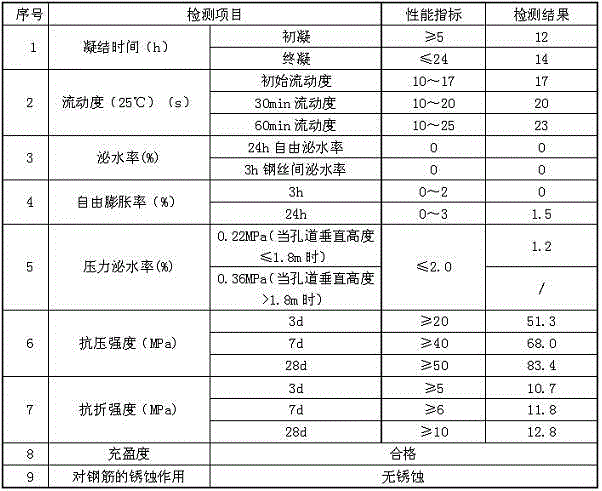

Embodiment 2

[0046] Example 2A post-tensioning prestressed pipeline grouting agent, the grouting agent is obtained by stirring the raw material components in the following weight percentage (kg) at a speed of not less than 1000r / min: water-reducing component 5.1%, plasticity Expansion component 0.5%, mid-late expansion component 30.1%, stabilizing component 0.2%, retarding component 0.5%, defoaming component 0.5%, superfine active mineral admixture 43.0%; sulphoaluminate cement 20.1% %.

[0047] in:

[0048] Water-reducing components, plastic expansion components, defoaming components, and sulphoaluminate cement are the same as in Example 1.

[0049] The middle and late expansion component refers to HEA expansion agent, and the manufacturer is Nanjing Pioneer Technology Industrial Co., Ltd.

[0050] The stabilizing component refers to hydroxypropyl methylcellulose, and the manufacturer is Gomez Chemical (China) Co., Ltd.

[0051] The retarding component refers to sodium gluconate, and...

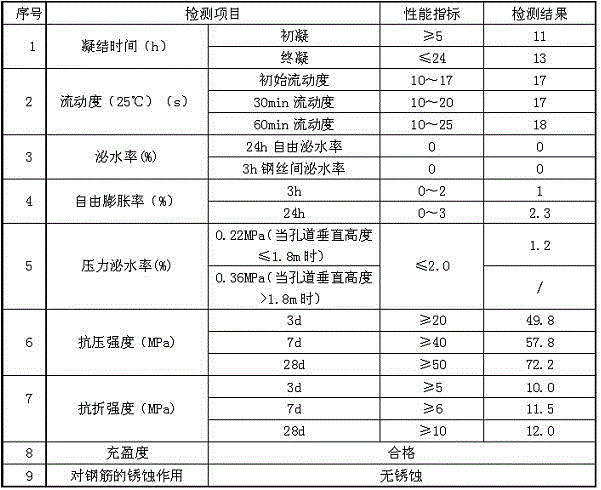

Embodiment 3

[0057] Example 3 A post-tensioning prestressed pipeline grouting agent, which is obtained by uniformly stirring the following raw material components in weight percentage (kg) at a speed of not less than 1000r / min: water-reducing component 5.0%, plasticity Expansion component 0.4%, mid-late expansion component 29.8%, stabilizing component 0.2%, retarding component 0.5%, defoaming component 0.4%, ultrafine active mineral admixture 43.3%; sulphoaluminate cement 20.4% %.

[0058] in:

[0059] Water-reducing components, plastic expansion components, defoaming components, sulphoaluminate cement, mid-late expansion components, stabilizing components, retarding components, superfine active mineral admixtures Example 1 .

[0060] When in use, the grouting agent is used to replace 11% of the amount of Portland or ordinary Portland cement with a strength not lower than 42.5, and the water-binder ratio is 0.27, and it is stirred evenly to make a grouting material for post-tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com