Anti-layering gel electrolyte for lead-acid storage battery and manufacturing method thereof

A colloidal electrolyte and lead-acid battery technology, applied in the direction of lead-acid batteries, can solve the problems of lead-acid battery capacity decline, end, hard top and soft battery life, etc., to reduce growth, inhibit passivation, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

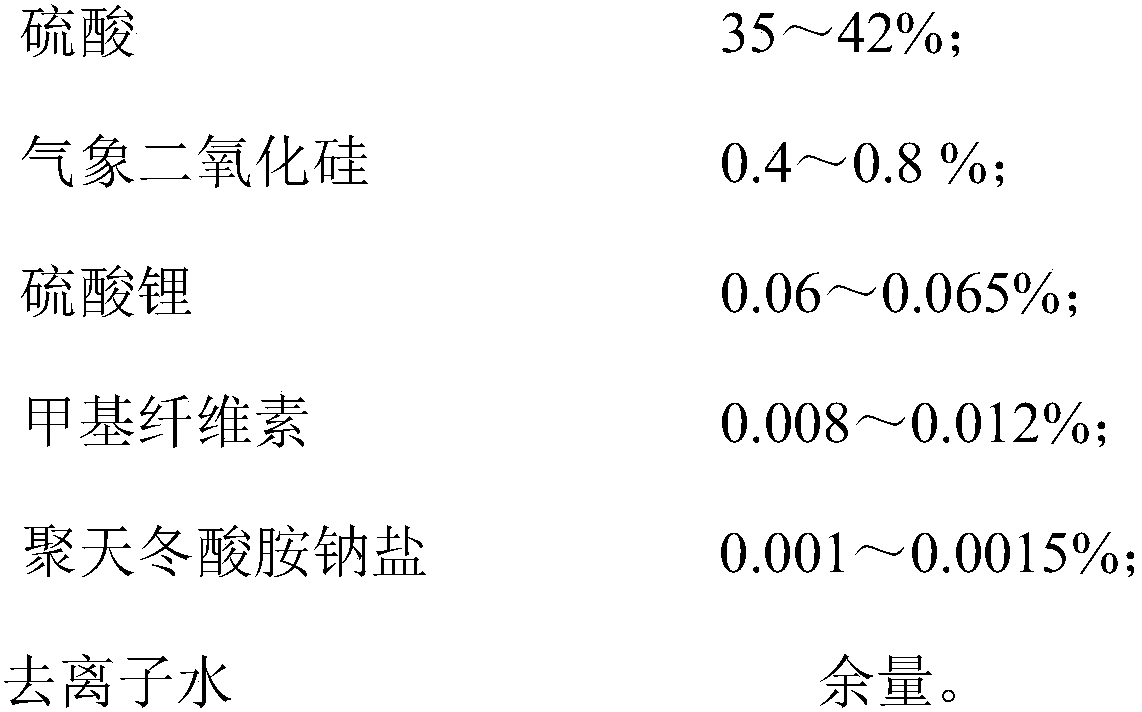

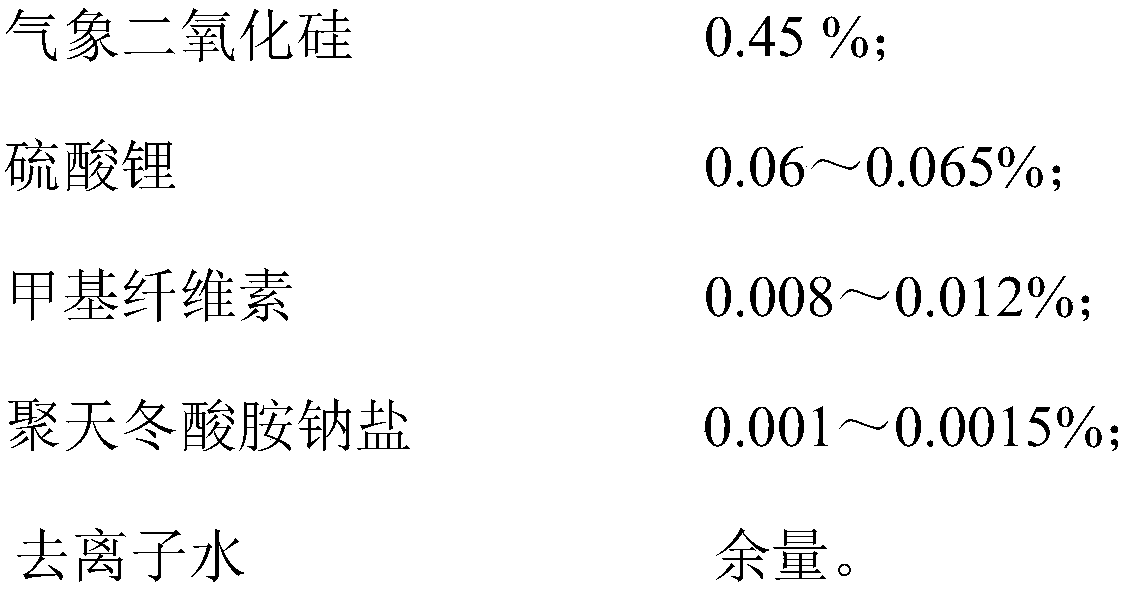

Method used

Image

Examples

Embodiment 1

[0031] Dissolve 0.55g of polyaspartic acid sodium salt in 5kg of deionized water, the stirring speed is 1200r / min, and the stirring time is 1min to obtain solution A; add 30.5g of lithium sulfate and heat up to 60°C, stop heating, and the stirring speed is 1200r / min, the stirring time is 10min to obtain solution B; add 4.1g methyl cellulose, the temperature is controlled at 50°C; the stirring speed is 4500r / min, the line speed is 15m / s, and the stirring time is 10min, to obtain solution C; add 45kg deionized water, the solution reaches room temperature, the stirring speed is 3500r / min, the linear speed is 15m / s, and the stirring time is 10min to obtain solution D, and 175g fumed silica is added to solution D while stirring, and the stirring speed is 3000r / min. The linear speed is 15m / s, the stirring time is 10min to obtain solution E, continue to stir for 30min after the addition is completed, slowly add 18kg of sulfuric acid to solution E, continue to stir for 30min after the ...

Embodiment 2

[0034] Dissolve 0.7g of polyaspartic acid sodium salt in 5kg of deionized water, the stirring speed is 1700r / min, and the stirring time is 10min to obtain solution A; add 32g of lithium sulfate and raise the temperature to 80°C, stop heating, and the stirring speed is 1700r / min, stirring time is 20min to obtain solution B; add 5.5g methyl cellulose, temperature control 60 ℃; stirring speed is 6000r / min, line speed 30m / s, stirring time is 120min, obtain solution C; add 45kg to Ionized water, the solution reaches room temperature, the stirring speed is 5000r / min, the line speed is 20m / s, and the stirring time is 20min to obtain solution D, and 375g fumed silica is added to solution D while stirring, the stirring speed is 4000r / min, and the line The speed was 20m / s, and the stirring time was 15min to obtain solution E. After the addition was completed, continue to stir for 50min. Slowly add 20.5kg of sulfuric acid to solution E. After the addition was completed, continue to stir ...

Embodiment 3

[0037]Dissolve 0.5g of polyaspartic acid sodium salt in 5kg of deionized water, the stirring speed is 1500r / min, and the stirring time is 8min to obtain solution A; add 31g of lithium sulfate and raise the temperature to 70°C, stop heating, and the stirring speed is 1500r / min, the stirring time is 15min to obtain solution B; add 5g of methyl cellulose, the temperature is controlled at 55°C; the stirring speed is 5000r / min, the line speed is 20m / s, and the stirring time is 15min, to obtain solution C; add 45kg deionized Water, the solution reaches room temperature, the stirring speed is 4000r / min, the line speed is 17m / s, and the stirring time is 15min to obtain solution D, and 300g fumed silica is added to solution D while stirring, the stirring speed is 3500r / min, and the line speed is 17m / s s, the stirring time is 13min to obtain solution E, continue to stir for 40min after the addition is completed, slowly add 38kg of sulfuric acid to solution E, continue to stir for 60min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com