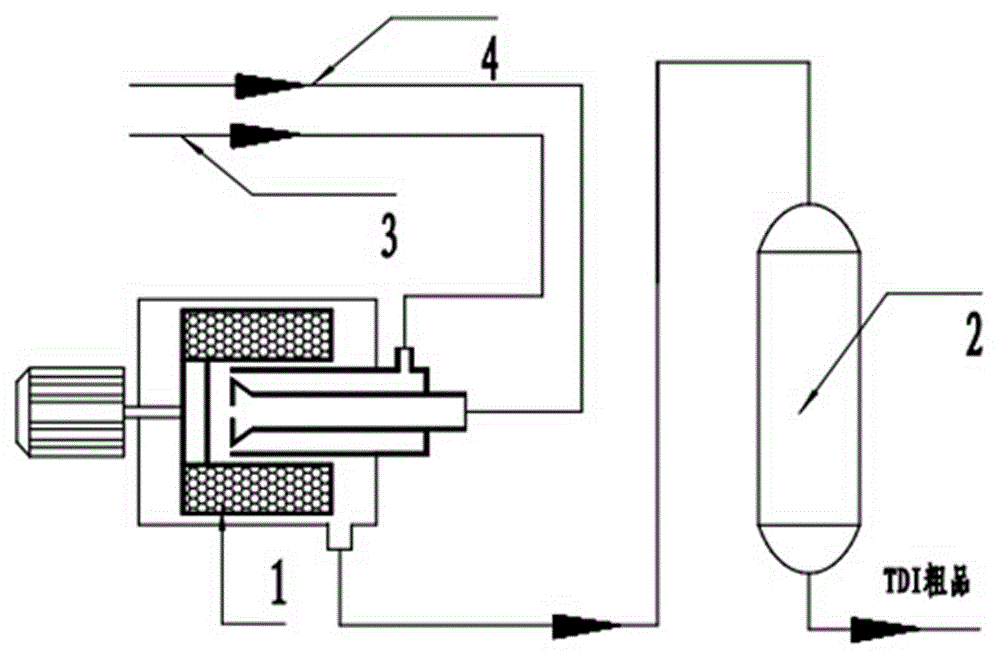

Single reflection hypergravity device and process for continuous preparation of toluene diisocyanate

A toluene diisocyanate and supergravity technology, applied in the field of single reflection supergravity devices, can solve the problems of poor reaction selectivity, decreased conversion rate, large difference in material volume flow ratio, etc., to avoid clogging and prevent urea substances. generated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

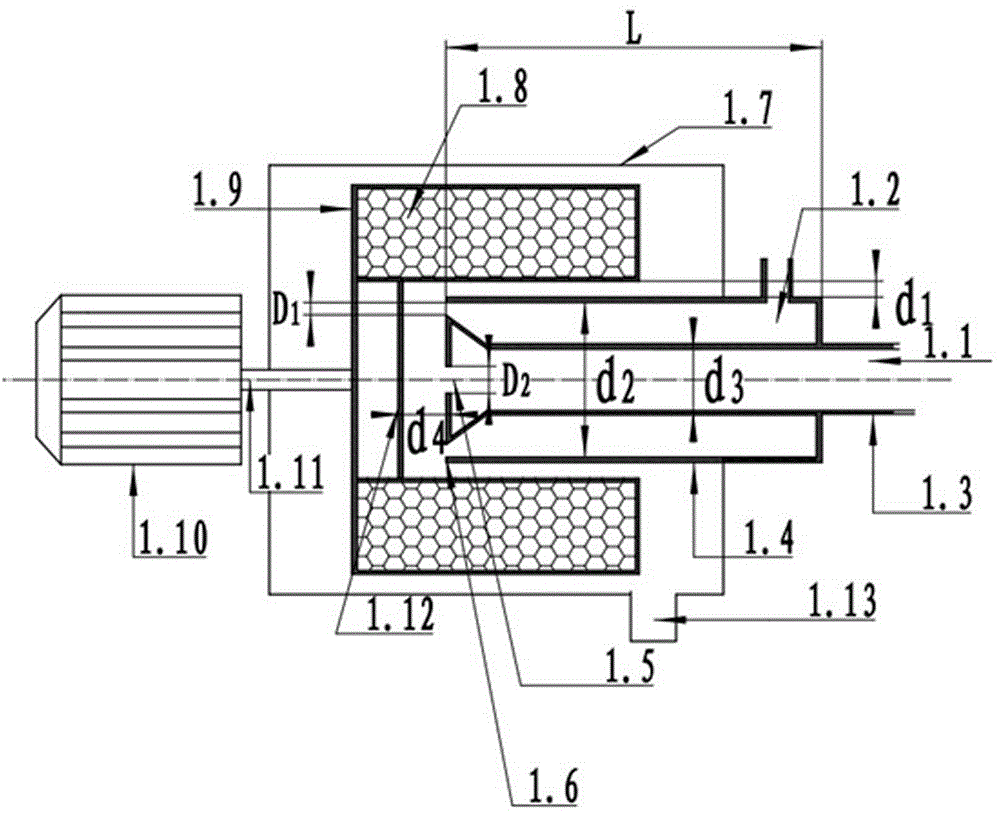

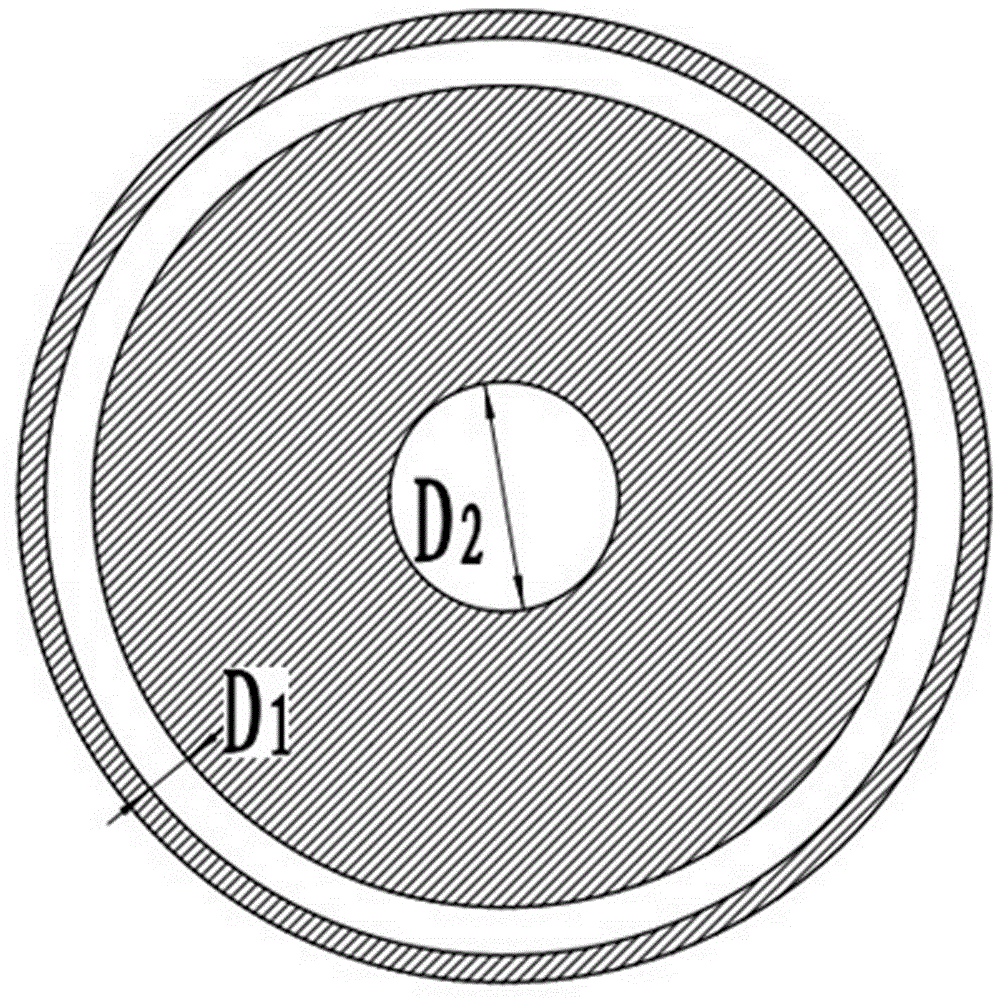

Embodiment 1

[0066] In a TDI manufacturer, the process and device of the present invention are used to carry out the pilot test, specifically as follows, using o-dichlorobenzene light solvent as the inert solvent, the temperature of the configured toluene diamine inert solvent solution is 110 ° C, the mass fraction is 40%, and the mass flow rate is 1000Kg / h; the temperature of phosgene inert solvent solution is 70°C, the mass fraction concentration of phosgene is 20%, the mass flow rate is 15240kg / h, the volume flow ratio of phosgene and toluenediamine inert solution is approximately 15:1, enter the cold The reactor is used for the reaction, and adopts a rotating packed bed type supergravity structure, and the filler is a wire mesh filler; the diameter of the casing is d 2 is 200mm, casing diameter d 2 and main feed pipe diameter d 3 With a ratio of 2, the diameter of the main feed pipe d 3 100mm; casing length L 1 with casing diameter d 2 The ratio is 10, the casing length L 1 is 20...

Embodiment 2

[0070] In a TDI manufacturer, the process and device of the present invention are used to carry out a pilot test, specifically as follows, using o-dichlorobenzene light solvent as an inert solvent, the temperature of the configured toluene diamine inert solvent solution is 150 ° C, the mass fraction is 10%, and the mass flow The rate is 9000kg / h; the temperature of the phosgene inert solvent solution is 110°C, the mass fraction concentration of phosgene is 50%, and the mass flow rate is 9500kg / h. Phosgene and toluene diamine inert solution have an approximate volume flow ratio of 1:1, and enter the cold reactor for reaction, adopting a stator-rotor type supergravity structure, and the filler is metal foam filler; the diameter of the casing is d 2 is 200mm, casing diameter d 2 and main feed pipe diameter d 3 With a ratio of 10, the diameter of the main feed pipe d 3 20mm; casing length L 1 with casing diameter d 2 The ratio is 1, the casing length L 1 is 200mm; the inner d...

Embodiment 3

[0073] In a TDI manufacturer, the process and device of the present invention are used to carry out a pilot test, specifically as follows with o-dichlorobenzene light solvent as an inert solvent, the temperature of the configured toluene diamine inert solvent solution is 140 ° C, the mass fraction is 40%, and the mass flow rate is 3020kg / h; the temperature of the phosgene inert solvent solution is 100°C, the mass fraction concentration of phosgene is 30%, and the mass flow rate is 10820kg / h. The volume flow ratio of phosgene and toluene diamine inert solution is approximately 3:1, enter the cold reactor for reaction, adopt spiral channel type supergravity structure, and the filler is metal foam filler; its characteristic is that the diameter of the sleeve is d 2 150mm, casing diameter d 2 and main feed pipe diameter d 3 With a ratio of 3, the diameter of the main feed pipe d 3 50mm; casing length L 1 with casing diameter d 2 Ratio is 2, sleeve length L 1 is 300mm; the inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com