A method for repairing leakage at the top of a kiln

A repair method and kiln technology, applied in lining repair and other directions, can solve problems such as secondary leakage, and achieve the effect of extending service life, repairing real leakage points, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0015] A method for repairing leakage at the top of a kiln is characterized in that it comprises the following steps:

[0016] (1) Carry out all cutting and dismantling of the furnace roof steel shell;

[0017] (2) Remove the furnace top insulation brick or diatomite layer;

[0018] (3) Purging and cleaning the surface of the refractory brick of the furnace body, including manual cleaning or mechanical cleaning, air flow purging or other gas purging and cleaning, and the surface is required to be free of ash and other foreign matter;

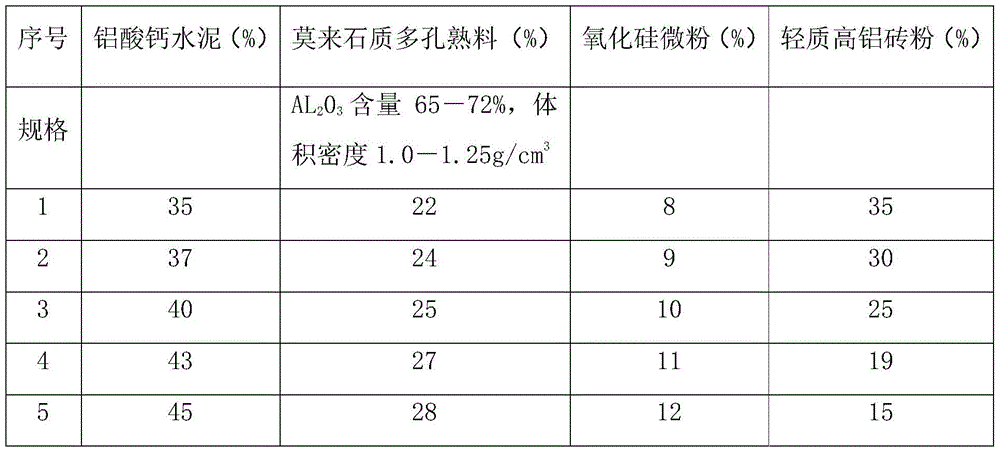

[0019] (4) Fill the gaps of refractory bricks with composite repair and plugging agent, and pour a layer of thickness 20-400mm on the furnace roof as a whole. After curing, lay a layer of light-weight thermal insulation material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com