Graphite bearing disc used for production process of LED epitaxial wafer

A carrier plate and epitaxy technology, which is used in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve the problems of uneven brightness of epitaxial wafers, low luminous intensity, and increased non-radiative composite luminescence, so as to improve luminescence. The effect of low intensity, reduced eddy current area, and improved brightness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

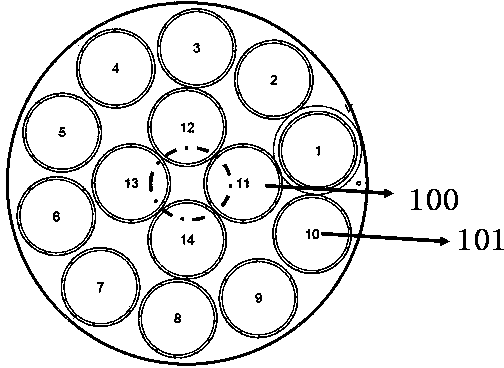

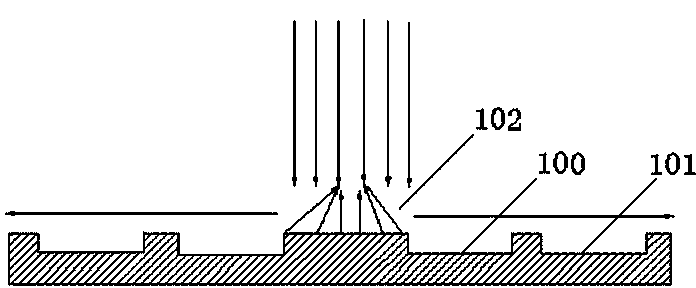

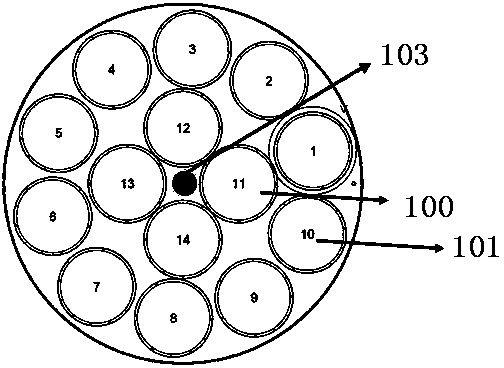

[0033] refer to Figure 3~Figure 4 As shown, a graphite carrier plate for LED epitaxial wafer manufacturing process includes: 14 4-inch wafer grooves arranged above the carrier plate, 4 wafer grooves 100 are distributed on the inner ring, and 10 wafer grooves are distributed on the outer ring The wafer groove 101 is used to place an epitaxial wafer substrate (not shown in the figure), wherein a convex structure 103 is provided in the center of the carrier plate, the center of which is high and the edge is low, serving as a flow guide layer for The vortex 102 at the center of the improvement.

[0034] In order to improve the vortex 102 at the center sufficiently and evenly, it is preferable that the protrusion structure is axisymmetric along the center of the carrier plate. In this embodiment, the shape of the protrusion structure is preferably hemispherical.

[0035] The material of the convex portion structure can be selected from graphite, silicon carbide, titanium metal, t...

Embodiment 2

[0039] refer to Figure 10 As shown, the difference from Example 1 is that the protrusion structure of this embodiment is curved, and the material of the protrusion structure is silicon carbide, which is formed on the central area of the carrier plate by bonding, thereby changing the central setting The gas flow rate and direction can be reduced to reduce the probability and area of thermal buoyancy convection, that is, eddy current, and improve the problem of low luminous intensity in the local area where the epitaxial wafer in the inner ring is facing the center of the carrier disk axis, thereby improving the uniformity of luminous intensity in the inner ring. Improve the overall brightness uniformity of the inner and outer ring epitaxial wafers.

Embodiment 3

[0041] refer to Figure 11As shown, different from Example 1, the convex structure of this example is triangular pyramid-shaped, as a guide layer, thereby changing the gas flow rate and direction arranged in the center, reducing the generation probability and area of thermal buoyancy convection, that is, eddy current, Improve the problem of low luminous intensity in the local area where the epitaxial wafers in the inner ring are facing the center of the carrier disk axis, thereby improving the uniformity of the luminous intensity of the inner ring and improving the overall uniformity of brightness of the epitaxial wafers in the inner and outer rings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com