Laminated packaging body based on glass adapter plate and preparation method of laminated packaging body

A technology of glass interposer and laminated packaging, which is applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., and can solve problems such as incomplete welding, electrical performance problems, and hidden cracks in welding areas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

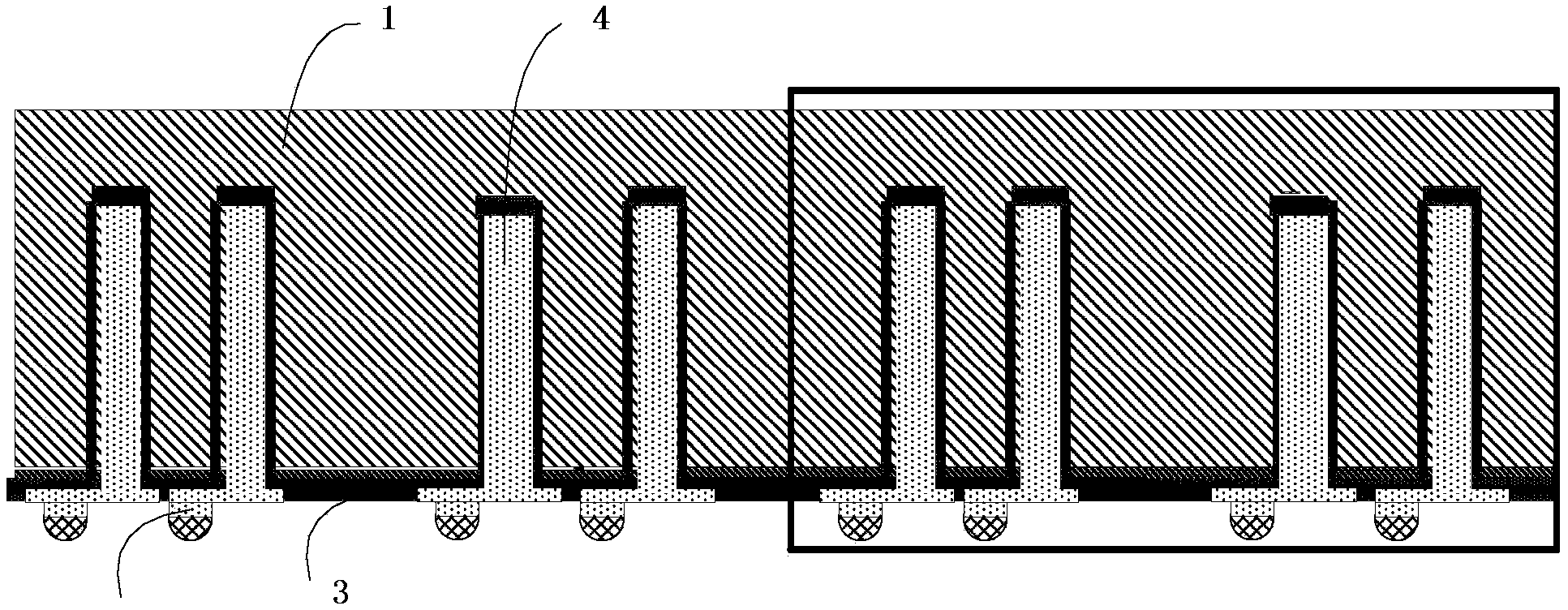

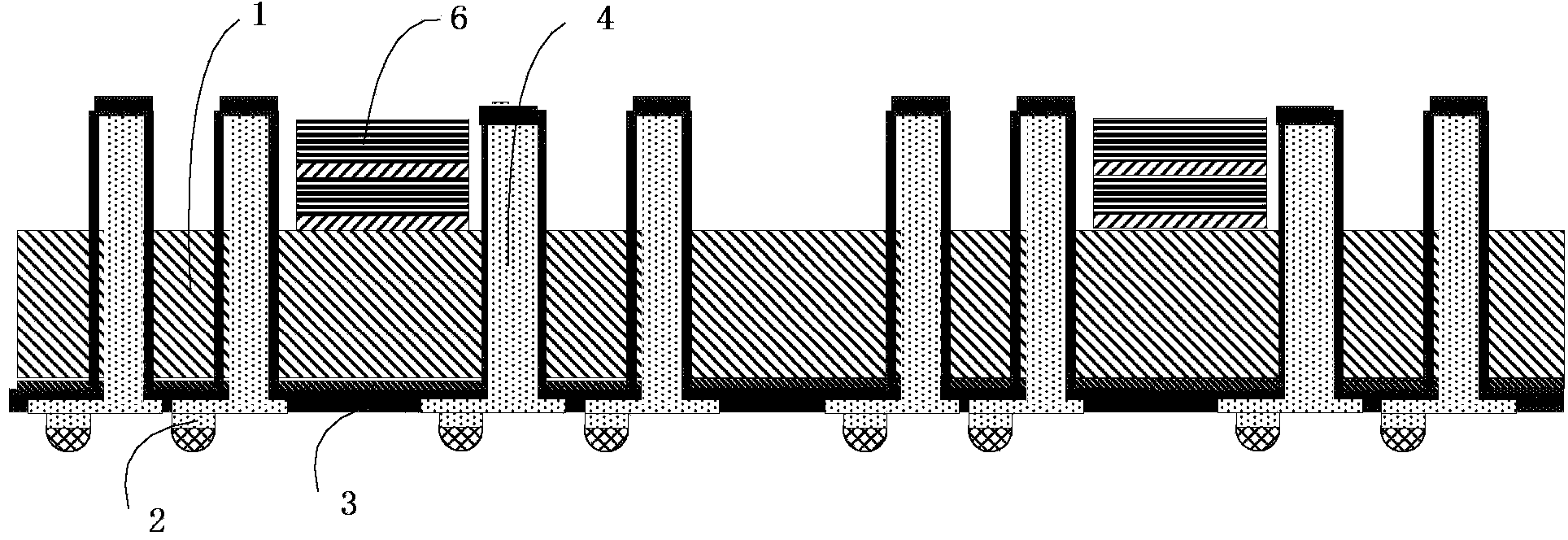

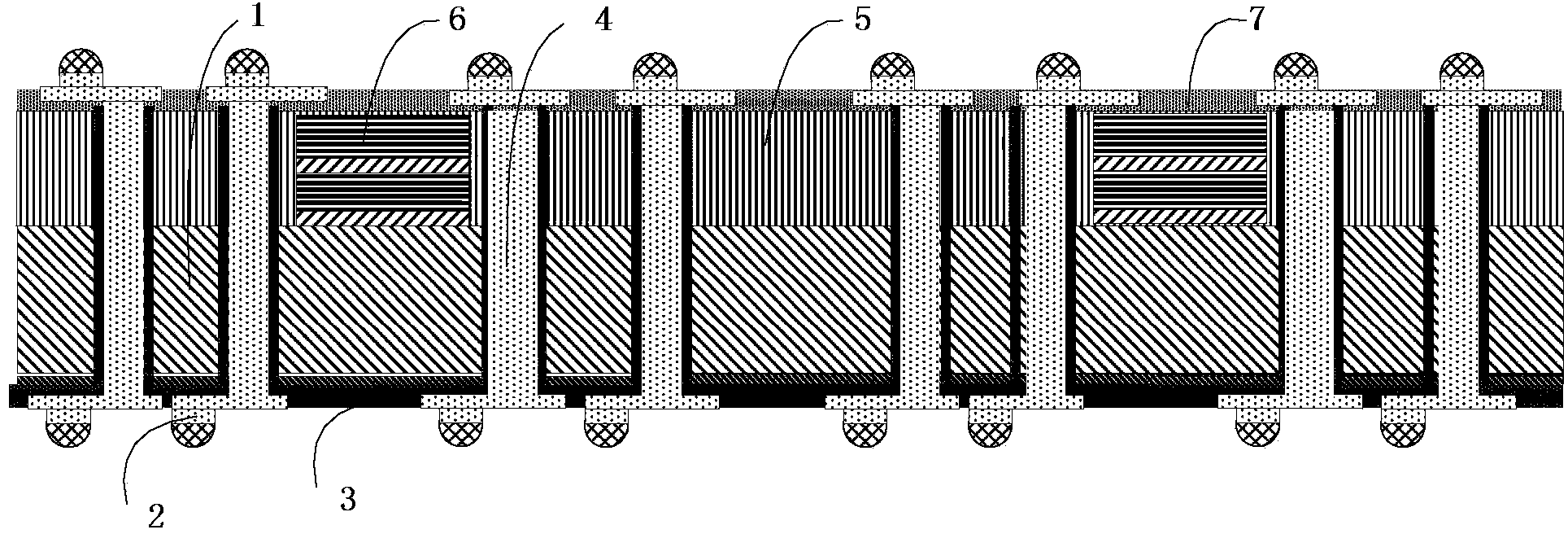

[0023] The first step of the method for preparing a laminated package based on the glass interposer provided by the present invention is to provide a glass interposer 1 . Vias are then made on it, using techniques such as wet etching, dry etching, deep reactive ion etching, or laser etching. Vias can have an aspect ratio of 10:1, a depth ranging from 30 to 300 microns, and a diameter as small as 5 microns. Subsequently, the filling of the metal in the through hole is completed to form the metal pillar 4. The filling method can be conventional electroplating filling or chemical vapor deposition, preferably electroplating filling. The filled metal material can be copper or tungsten, preferably copper. If the hole depth value is small. And prepare the front wiring 2 and the insulating layer 3, the schematic diagram of the structure after the end is as follows figure 1 As shown, the black box represents the area of a chip.

[0024] Next, the back side of the glass interposer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com