Hardening composition

A composition and compound technology, applied in the direction of electric solid device, semiconductor/solid device parts, coating, etc., can solve the problem that the encapsulant does not have heat resistance and light resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

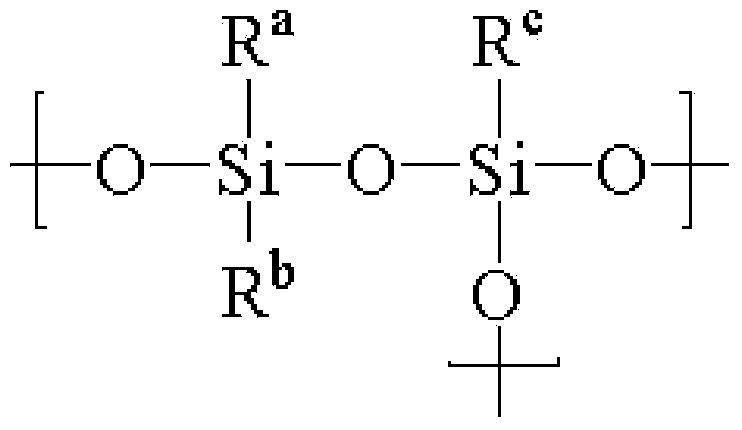

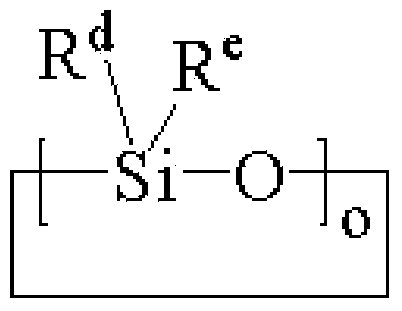

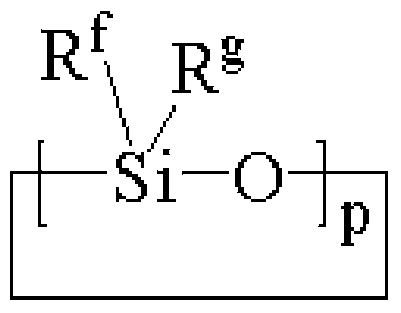

[0177] A curable composition that can be cured by hydrosilylation is prepared by mixing compounds represented by formula A to formula D (mixing amount: formula A: 70 g, formula B: 200 g, formula C: 70 g, formula D: 4 g). Here, in the presence of a catalyst (for example, tetramethylammonium hydroxide (TMAH)), at about 115°C, a mixture of octamethylcyclotetrasiloxane and octaphenylcyclotetrasiloxane is combined with two The vinyl tetramethyl disiloxane is reacted for about 20 hours to prepare the polyorganosiloxane of formula A, and other compounds other than the polyorganosiloxane of formula A are prepared by known synthetic methods. Subsequently, a catalyst (platinum(0)-1,3-divinyl-1,1,3,3-tetramethyldisiloxane) was mixed into the composition at a content of 10ppm Pt(0), and 20g Hollow imogolites with an outer diameter of about 2 mm and a length of about 400 nm are uniformly mixed to prepare a curable composition.

[0178] [Formula A]

[0179] (ViMe 2 SiO 1 / 2 ) 2 (Me 2 SiO 2 / 2 ) ...

Embodiment 2

[0187] A curable composition that can be cured by hydrosilylation is prepared by mixing compounds represented by formulas E, F, C and D (mixing amount: formula E: 70 g, formula F: 200 g, formula C: 70 g, formula D: 4 g) . Here, in the presence of a catalyst such as tetramethylammonium hydroxide (TMAH), a mixture of octamethylcyclotetrasiloxane and tetramethyltetraphenylcyclotetrasiloxane is combined with divinyltetrasiloxane The methyldisiloxane is reacted to prepare the polyorganosiloxane of formula E, and the compounds other than the polyorganosiloxane of formula E are prepared by known synthetic methods. Subsequently, a catalyst (platinum(0)-1,3-divinyl-1,1,3,3-tetramethyldisiloxane) was mixed into the composition at a content of 10ppm Pt(0), and approximately 20 g of hollow hallucinite with an inner diameter of about 50 mm and a length of about 8,000 nm was uniformly mixed to prepare a curable composition.

[0188] [Formula E]

[0189] (ViMe 2 SiO 1 / 2 ) 2 (PhMeSiO 2 / 2 ) 26 (...

Embodiment 3

[0197] A curable composition that can be cured by hydrosilylation is prepared by mixing compounds represented by formulas G, H, C and D (mixing amount: formula G: 70 g, formula H: 200 g, formula C: 70 g, formula D: 4 g) . Here, using a catalyst such as tetramethylammonium hydroxide (TMAH), at an appropriate temperature, by making octamethylcyclotetrasiloxane, octaphenylcyclotetrasiloxane, and octaphenyl-polyhedron low A mixture of polysilsesquioxane (octaphenyl-POSS) and divinyltetramethyldisiloxane is reacted to prepare polyorganosiloxane of formula G, and other compounds are prepared by known synthetic methods. Subsequently, a catalyst (platinum(0)-1,3-divinyl-1,1,3,3-tetramethyldisiloxane) was mixed into the composition at a content of 10ppm Pt(0), and approximately 20 g of hollow hallucinite with an inner diameter of about 30 mm and a length of about 10,000 nm was uniformly mixed to prepare a curable composition.

[0198] [Formula G]

[0199] (ViMe 2 SiO 1 / 2 ) 2 (Me 2 SiO 2 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com