Preparation method of molecular sieve membrane

A molecular sieve and seed crystal technology, applied in molecular sieve compounds, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problems of complex operation, inability to realize large-scale application, and high requirements for condition control, and achieve good repeatability , High secondary growth activity, high success rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In this embodiment, the dynamic wetting method is used to coat the seed layer, and the secondary growth method is used to synthesize the TS-1 molecular sieve membrane.

[0051] The first step, the dynamic wetting method to prepare the seed layer:

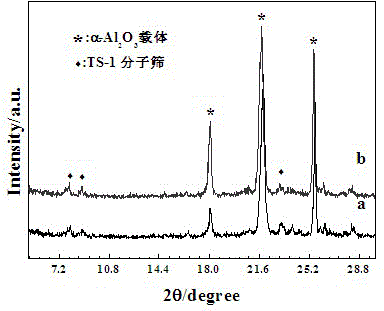

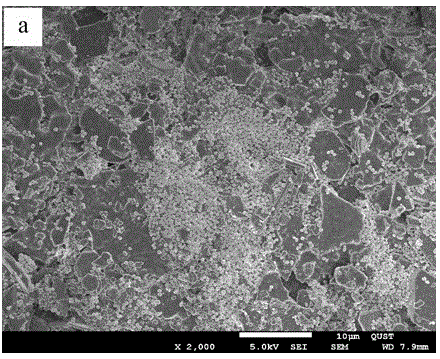

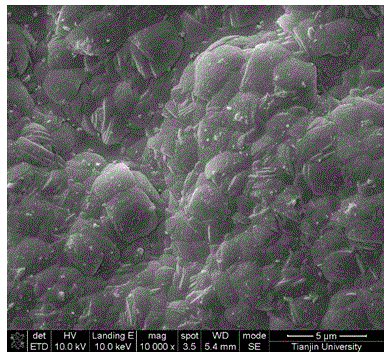

[0052]Disperse 0.20 g of TS-1 molecular sieve with a particle size of 400 nm in 19.80 g of absolute ethanol at 75°C to prepare a 1wt.% seed crystal suspension; then immerse the carrier in the seed crystal solution and take it out after 10 s; Drying: drying at 60 °C for 0.5 h; roasting: roasting at 600 °C for 3 h, the seeds are evenly dispersed in the surface defects of the carrier, and the XRD and SEM of the seed layer are shown in the attached figure 1 , 2 , a small amount of nano-crystal seeds are embedded on the surface of the carrier.

[0053] The second step, the secondary growth method to prepare TS-1 molecular sieve membrane:

[0054] The molar composition of the secondary growth solution is 1.00 TEOS : 0.05 TiO 2 ...

Embodiment 2

[0068] In this embodiment, the dynamic wetting method is used to coat the seed layer, and the secondary growth method is used to synthesize the Silicalite-1 molecular sieve membrane.

[0069] The same part of this embodiment and embodiment 1 will not be repeated, the difference is:

[0070] In the second step, the Silicalite-1 molecular sieve membrane is prepared by the secondary growth method,

[0071] Concrete synthetic steps are identical with example 1, but do not add titanium source. The structure of the synthesized Silicalite-1 molecular sieve membrane is similar to that of TS-1 molecular sieve membrane, and its XRD is shown in Figure 5 (d). Single-component He gas permeation experiment detects that its flux is less than 10 -10 mol / (m 2 ·s·Pa), indicating that the molecular sieve membrane has good compactness.

Embodiment 3

[0073] In this embodiment, the dynamic wetting method is used to coat the seed layer, and the secondary growth method is used to synthesize the TPAO-5 molecular sieve membrane.

[0074] The same part of this embodiment and embodiment 1 will not be repeated, the difference is:

[0075] In the first step, in the preparation of the seed layer by the dynamic wetting method, 0.20 g of semi-crystalline TAPO-5 molecular sieve was dispersed in 19.80 g of absolute ethanol at 75°C to obtain a 1wt.% seed crystal suspension; the remaining steps Same as Example 1. The seeds are uniformly dispersed in the surface defects of the carrier, and the seed layer XRD and SEM respectively see Figure 11 (a), Figure 12 .

[0076] The second step, the secondary growth method to prepare TAPO-5 molecular sieve membrane:

[0077] The molar composition of the growth solution is 0.05 TiO 2 : 1.00 Al 2 o 3 : 1.10 P 2 o 5 : 1.50 TEA : 105 H 2 O: 0.10H 2 o 2 . Phosphoric acid (H 3 PO 4 , 85...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com