Dry gas recovery system and dry gas recovery method for refinery plant

A refinery dry gas and recovery system technology, which is applied in the processing of gas mixtures, the petroleum industry, and the treatment of hydrocarbon oil, can solve the problems of large investment, high energy consumption, and limited process applicability, so as to reduce energy consumption and Investment, energy consumption reduction, ideal absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

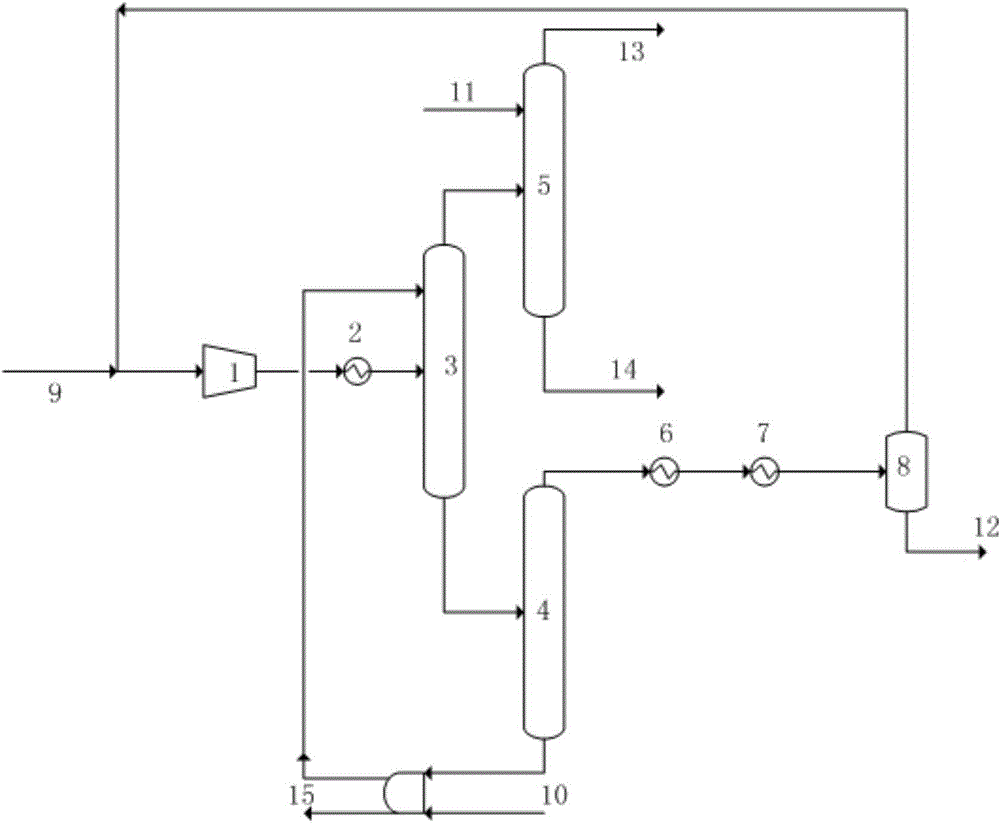

[0057] Such as figure 1 As shown, a refinery dry gas recovery system. Including: compressor 1, absorption tower 3, reabsorption tower 5, desorption tower 4, propylene refrigerant cooler 6, ethylene refrigerant cooler 7 and flash tank 8;

[0058] Compressor 1 is connected to heat exchanger 2 and then connected to absorption tower 3, the top of absorption tower 3 is connected to reabsorption tower 5, the bottom of absorption tower 3 is connected to desorption tower 4, and the top of desorption tower 4 is connected to propylene refrigerant cooler 6 and ethylene refrigerant cooling Device 7 and flash tank 8, the top of flash tank 8 is connected to the compressor 1 inlet; the absorption tower 2 is provided with an absorption tower still reboiler;

[0059] The dry gas composition is shown in Table 1,

[0060] Table 1

[0061] composition

[0062] The incoming material of refinery dry gas is 26700kg / h, and carbon four after ether is selected as the absorbent to recover e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com