Antibacterial water pipe

A technology of water pipes and stainless steel pipes, applied in the field of antibacterial water pipes, can solve the problems of insufficient strength of plastic hot-melt pipes, easy breeding of bacterial derivatives, secondary pollution of water resources, etc., achieve good self-cleaning effect, small expansion coefficient, and guarantee Effect of Liquid Velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

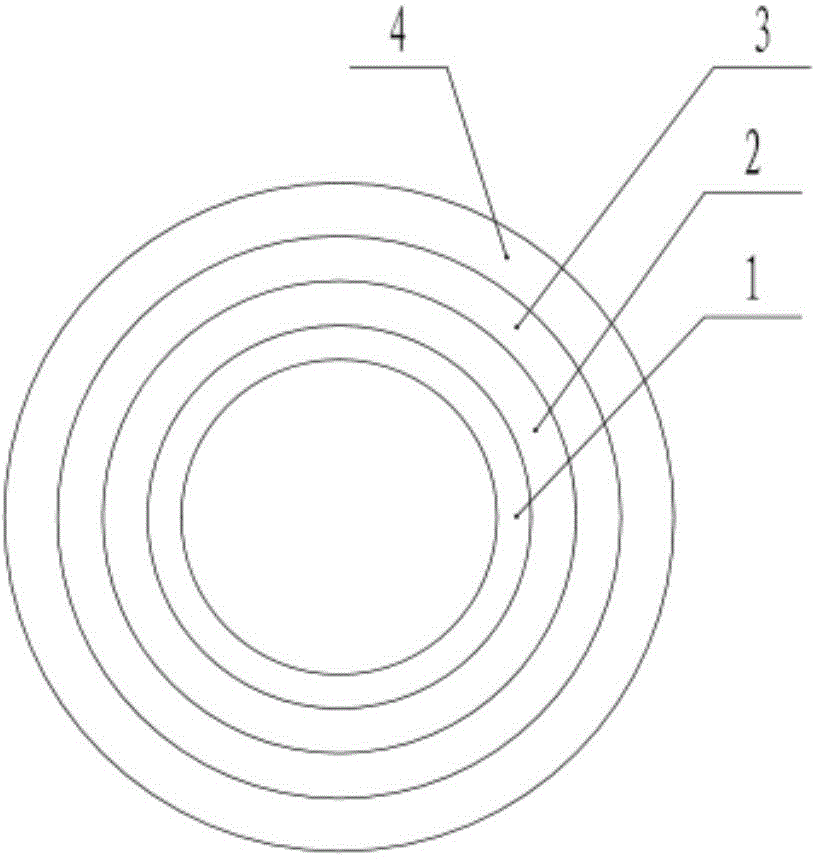

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] like figure 1 Shown: an antibacterial water pipe, comprising a stainless steel pipe main body 4, a glass fiber mesh layer 3 is arranged inside the stainless steel pipe main body 4, a polypropylene layer 2 is arranged inside the glass fiber mesh layer 3, and the inner side of the polypropylene layer 2 is coated with The nano-copper layer 1 has a thickness of 0.1-0.5 mm.

[0012] The present invention is provided with a glass fiber mesh layer 3, so that the water pipe is resistant to stretching, high in strength, and small in expansion coefficient, and the nano-copper layer 1 has an antibacterial effect, and can eliminate Staphylococcus aureus, Staphylococcus albicans, and Candida albicans to a certain extent , Bacillus subtilis, Escherichia coli, Neisseria gonorrhoeae, halophilic bacteria, Pseudomonas aeruginosa, typhoid bacillus, Streptococcus beta and other ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com