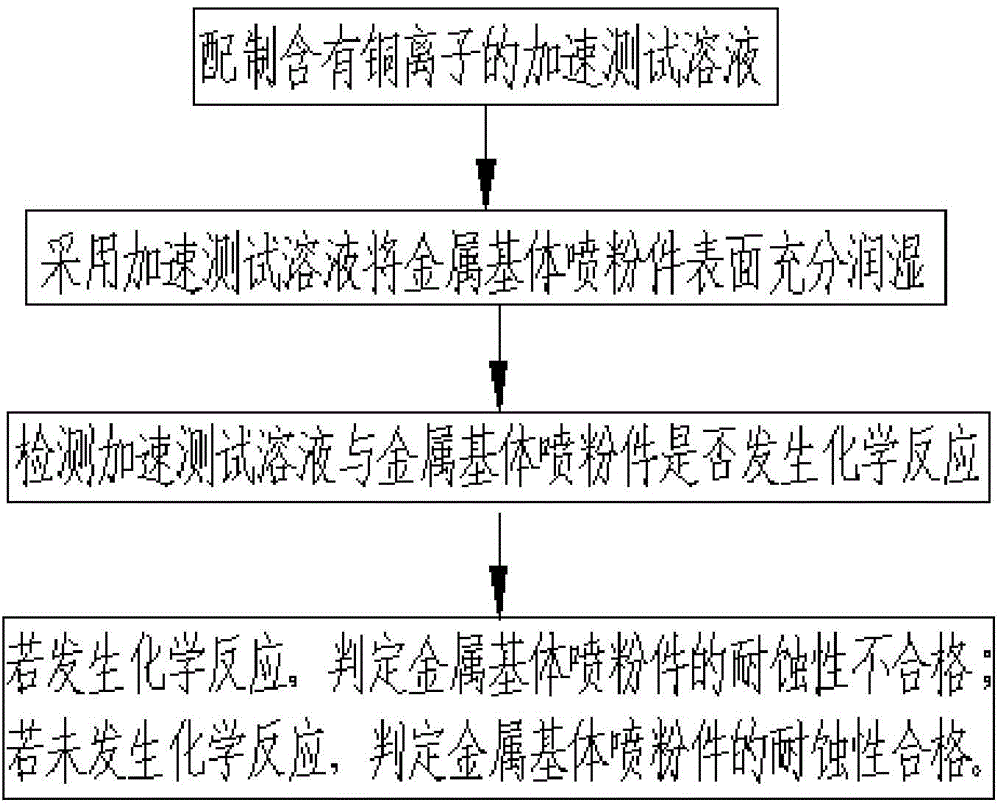

Acceleration test solution and method for detecting corrosion resistance of metallic substrate powder spraying part by adopting same

A technology of metal substrates and detection methods, which is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of low-cost and fast testing of powder-sprayed products, long test cycle, and large errors, etc., to achieve The effect of reducing experiment cost, convenient operation and reducing maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

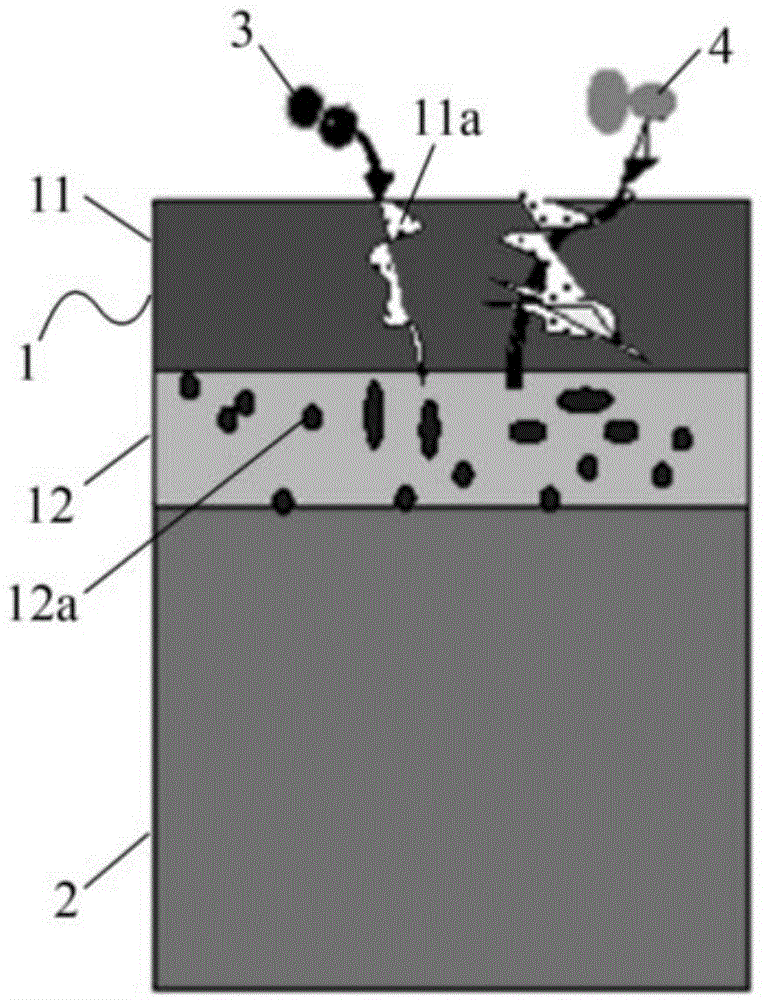

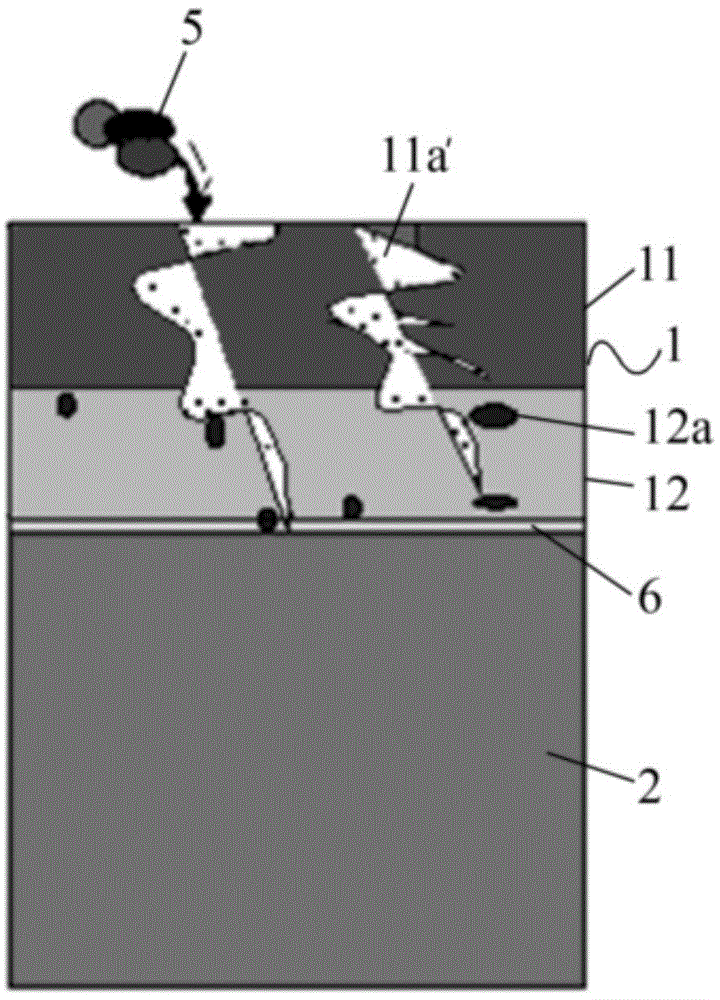

[0085] In this embodiment, according to the coating thickness of the metal base powder spraying parts, the metal base powder spraying parts with a coating thickness of 60 μm are marked as the first group, and the metal base powder spraying parts with a coating thickness of 100 μm are marked as the second group. Group, the metal matrix powder sprayed parts with a coating thickness of 150 μm are marked as the third group; and the surface of the metal matrix powder sprayed parts of the three groups is cleaned to make the surface free of dust and oil.

[0086] In the present embodiment, when preparing the accelerated test solution, the percentage by weight of each component is: 0.1% copper chloride: 3% sodium chloride: 0.5% surfactant: 96.4% deionized water, so that the accelerated test solution The pH value is 5.0, and the temperature is 75°C; then, divide the prepared accelerated test solution into three parts on average, and then immerse the three groups of metal substrate powde...

Embodiment 2

[0091] In the present embodiment, when preparing the accelerated test solution, the weight percentage of each component is: copper chloride 5%: sodium chloride 6.5%: surfactant 0.1%: deionized water 88.4%, the pH value of the accelerated test solution is 3.0, the temperature of the accelerated test solution is 20°C.

[0092] In this embodiment, the process of pre-treating the powder-sprayed parts of the metal base and the method of detecting whether the chemical reaction between the accelerated test solution and the powder-sprayed parts of the metal base are the same as those in Embodiment 1, and will not be repeated here.

[0093] Table 1 shows the color change of the surface of each group of powder-sprayed metal parts in this embodiment and the corresponding corrosion resistance evaluation results at different times.

Embodiment 3

[0095] When preparing the accelerated test solution in the present embodiment, the percentage by weight of each component is: copper chloride 0.3%: sodium chloride 5%: surfactant 0.5%: deionized water 94.2%, and the pH value of the accelerated test solution is 3.7 , the temperature of the accelerated test solution is 50°C.

[0096] In this embodiment, the process of pre-treating the powder-sprayed parts of the metal base and the method of detecting whether the chemical reaction between the accelerated test solution and the powder-sprayed parts of the metal base are the same as those in Embodiment 1, and will not be repeated here.

[0097] Table 1 shows the color change of the surface of each group of powder-sprayed metal parts in this embodiment and the corresponding corrosion resistance evaluation results at different times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com