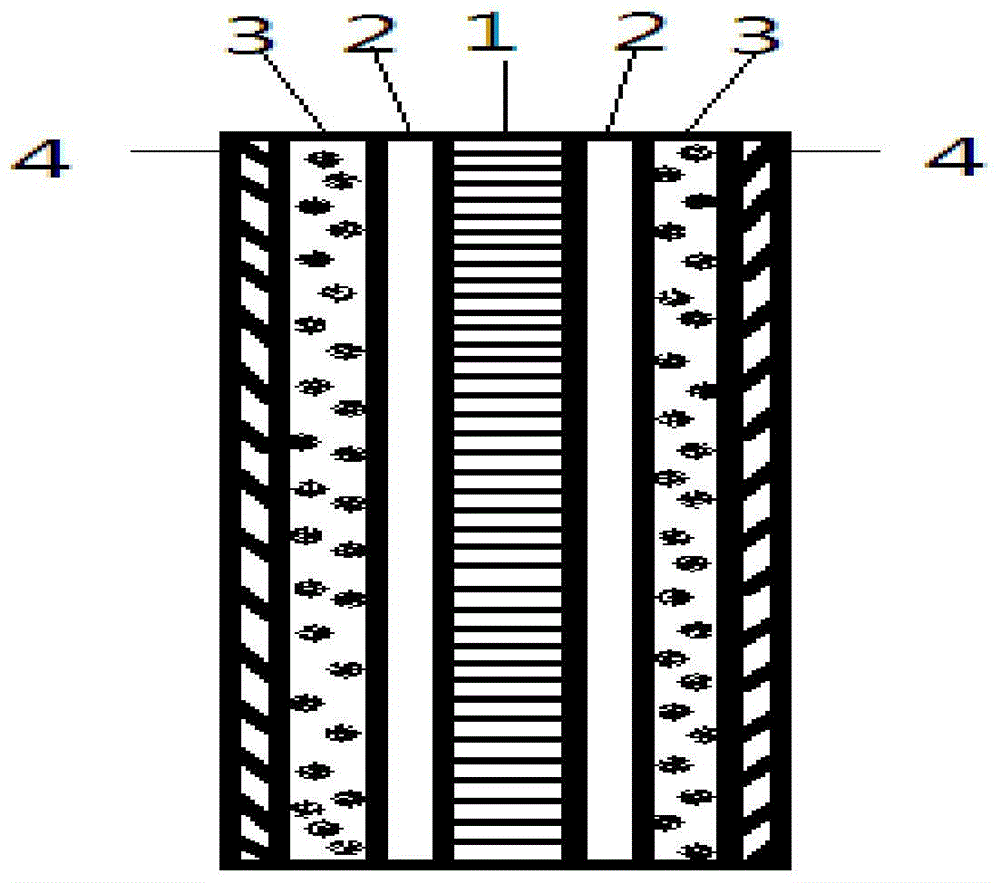

Preparation method of membrane electrode with transition layer for basic anion-exchange membrane fuel battery

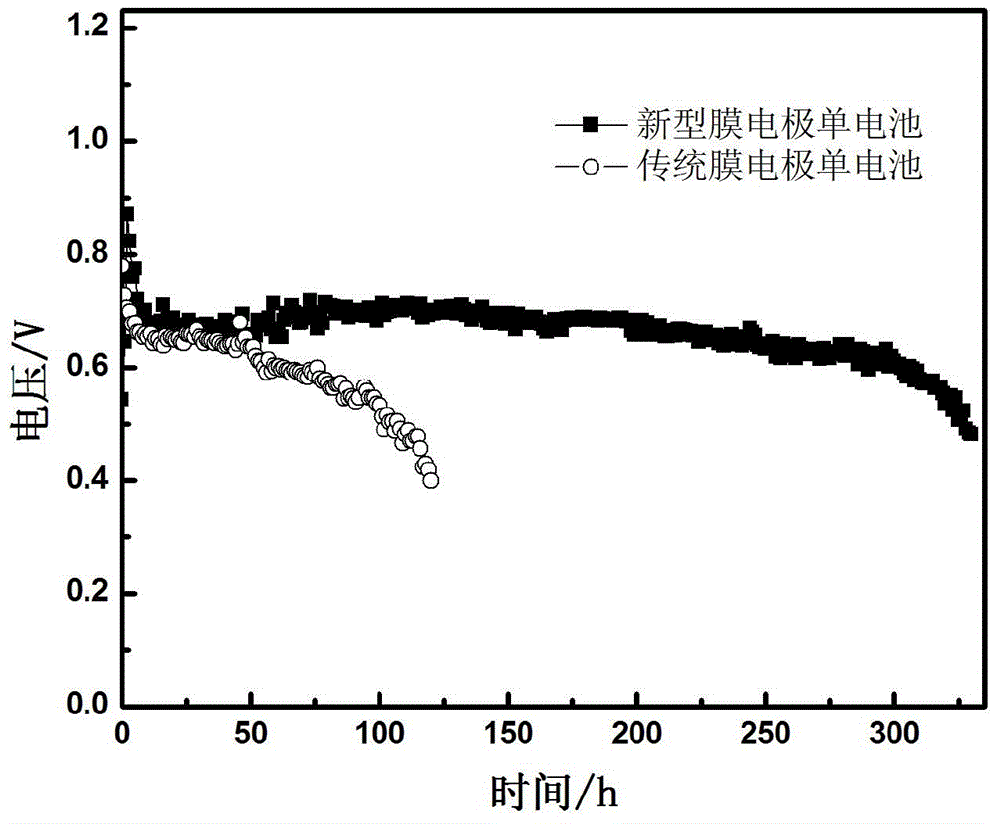

A basic anion and transition layer technology, applied in the direction of fuel cells, battery electrodes, circuits, etc., can solve the problems of catalysts falling off easily, achieve the promotion of OH- conduction, improve performance and stability, and expand the three-phase reaction interface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

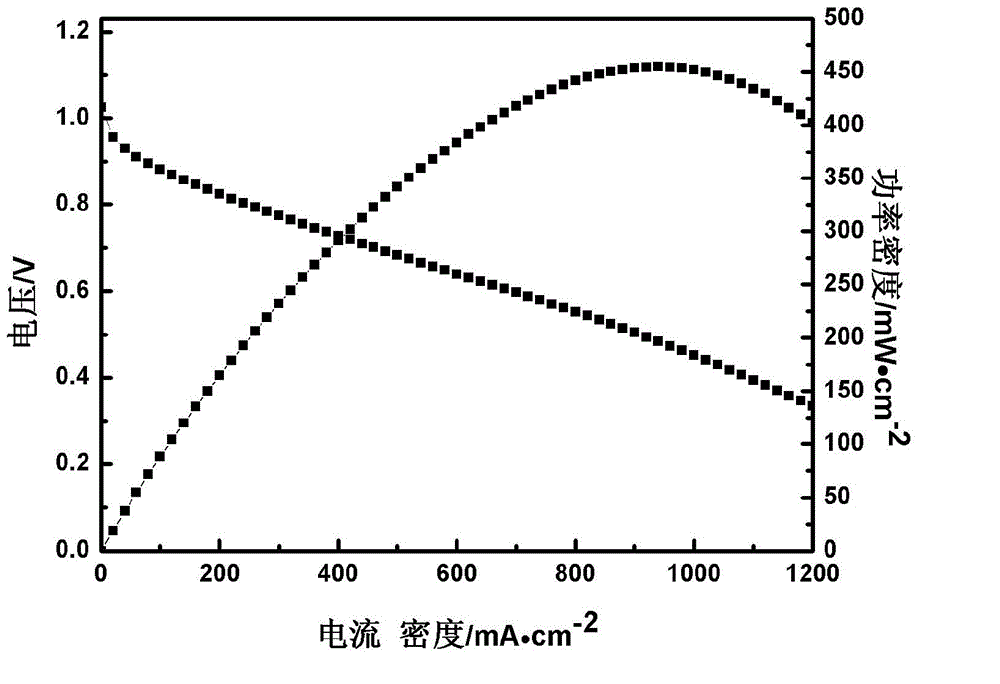

Examples

Embodiment 1

[0025] Described membrane electrode is made by following method:

[0026] Select A201 type alkaline anion exchange membrane from Tokuyama Company, Japan, 24cm 2 .

[0027] Take 0.035g of 5wt% AS-4 anion exchange resin produced by Tokuyama Corporation in Japan, add 0.78g of isopropanol, disperse for 40min by ultrasonic dispersion, and mix them evenly to obtain a mixed solution of anodic and anode transition layers.

[0028] Weigh 0.035g of a 70% Pt / C catalyst by weight, add 1.05g of isopropanol as a solvent, and disperse ultrasonically for 40 minutes, then add 0.10g of 5wt% AS-4 anion exchange resin, and disperse ultrasonically for 40 minutes to obtain a uniform catalyst slurry .

[0029] On a hot stage at 55°C, first spray the transition layer solution on both sides of the basic anion exchange membrane, and then spray the catalytic layer slurry on the surface of the basic anion exchange membrane with the transition layer. Cool to obtain a transition layer catalytic layer fi...

Embodiment 2

[0036] A201-CE basic anion exchange membrane from Tokuyama Company, Japan, with an area of 24cm 2 .

[0037] Take 0.04g of 5wt% AS-CEX anion exchange resin produced by Tokuyama Corporation in Japan, add 0.78g of isopropanol, and disperse for 40min by ultrasonic dispersion to make them evenly mixed to obtain a mixed solution of anodic and anode transition layers.

[0038] Weigh 0.035g of a 70% Pt / C catalyst by weight, add 1.05g of isopropanol as a solvent, and disperse ultrasonically for 40 minutes, then add 0.12g of 5wt% AS-CEX anion exchange resin, and disperse ultrasonically for 40 minutes to obtain a uniform catalyst slurry .

[0039] On a hot stage at 60°C, first spray the cathode and anode transition layer solution on both sides of the basic anion exchange membrane, and then spray the cathode and anode catalyst layer slurry on the surface of the alkaline anion exchange membrane with the cathode and anode transition layers, After the solvent is completely evaporated, i...

Embodiment 3

[0045] Self-crosslinked QAPS alkaline anion exchange membrane with an area of 24cm 2 .

[0046]Take 0.05g of a 5wt% AS-4 three-dimensional resin solution produced by Tokuyama Corporation in Japan, add 0.78g of isopropanol, and disperse for 40 minutes by ultrasonic dispersion to make it evenly mixed to obtain a mixed solution of an anode-cathode transition layer.

[0047] Weigh 0.035g of a 70% Pt / C catalyst by weight, add 1.05g of isopropanol as a solvent, and disperse ultrasonically for 40 minutes, then add 0.12g of 5wt% AS-4 anion exchange resin, and disperse ultrasonically for 40 minutes to obtain a uniform catalyst slurry .

[0048] On a hot stage at 70°C, first spray the cathode and anode transition layer solution on both sides of the basic anion exchange membrane, and then spray the cathode and anode catalyst layer slurry on the surface of the alkaline anion exchange membrane with the cathode and anode transition layers. After the solvent is completely evaporated, it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com