Envelope-type functional chocolate and making method thereof

A technology of chocolate and chocolate paste, applied in the field of chocolate, which can solve the problems of unsaturated fatty acids being easily oxidized, affecting product quality, shortening shelf life, etc., achieving the effects of mellow taste, enhancing immunity and reducing calories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

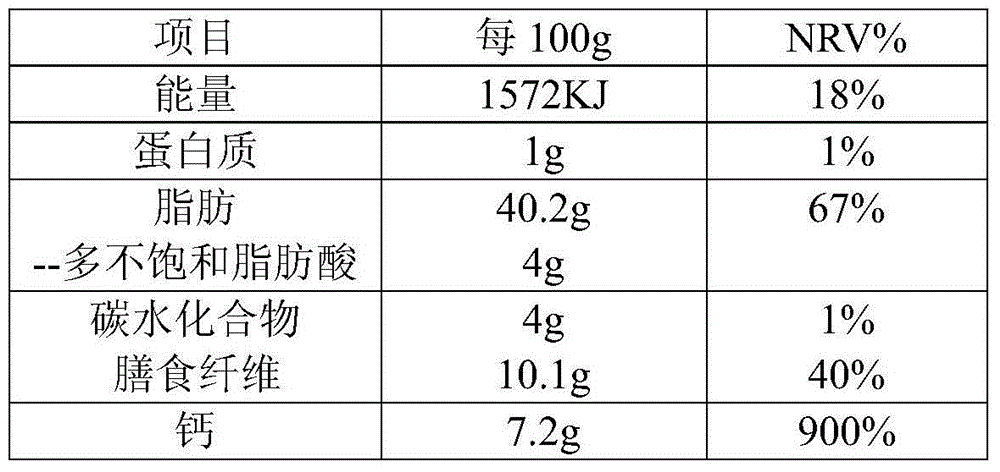

Embodiment 1

[0040] Ingredients for Chocolate Sauce:

[0041] Cocoa Butter 35kg Sugar Alcohol 10kg Milk Mineral Salt 30kg

[0042] Fruit Powder 10kg DHA Oil 5kg Resistant Dextrin 10kg

[0043] Film raw material formula:

[0044] Modified starch 20kg Gelatin 20kg Gellan gum 0.5kg

[0045] Brown sugar 2kg Glycerin 20kg Purified water 32.5kg

[0047] A method for making film-type functional chocolate, comprising the steps of:

[0048] 1) Preparation of chocolate sauce: according to the recipe of chocolate sauce, first place 35kg of cocoa butter in a water bath at 45°C, heat and melt. Then sugar alcohol and fruit powder (coconut powder) are pulverized, and the particle size can pass through a 100-mesh sieve for subsequent use. When the cocoa butter is completely melted, 30kg of milk mineral salt, 10kg of sugar alcohol, 10kg of fruit powder (coconut powder), 10kg of resistant dextrin and 5kg of DHA oil are sequentially added to the cocoa butter, and mixed with a...

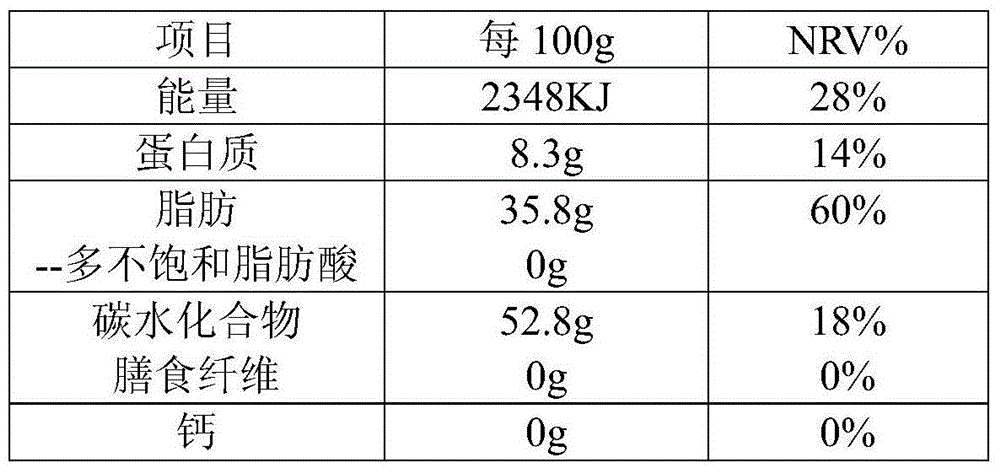

Embodiment 2

[0068] Ingredients for Chocolate Sauce:

[0069] Cocoa Butter 30kg Sugar Alcohol 10kg Milk Mineral Salt 16kg

[0070] Fruit powder 5kg DHA oil 12kg Dietary fiber 27kg

[0071] Film raw material formula:

[0072] Modified starch 30kg Gelatin 10kg Gellan gum 1kg

[0073] Brown sugar 5kg glycerin 10kg purified water 34kg

[0074] Sugar alcohol 10kg

[0075] A method for making film-type functional chocolate, comprising the steps of:

[0076] 1) Preparation of chocolate sauce

[0077] According to the raw material formula of the chocolate sauce, first place 30kg of cocoa butter in a water bath at 50°C and heat to melt. Then sugar alcohol and fruit powder (apple powder) are pulverized, and the particle size can pass through a 300-mesh sieve for subsequent use. When the cocoa butter is completely melted, add 16kg of milk mineral salt, 10kg of sugar alcohol, 5kg of fruit powder (apple powder), 27kg of dietary fiber (apple fiber) and 12kg of DHA oil into the cocoa butter in seq...

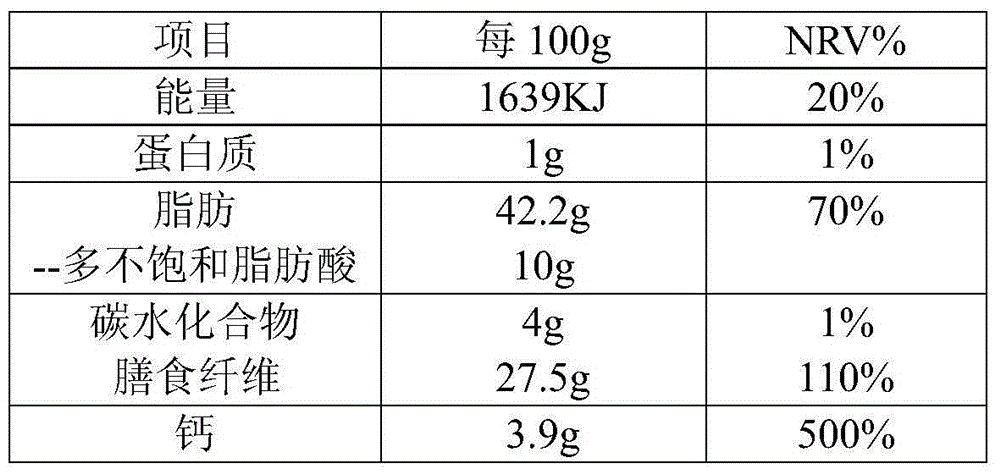

Embodiment 3

[0096] Ingredients for Chocolate Sauce:

[0097] Cocoa Butter 35kg Sugar Alcohol 6.4kg Milk Mineral Salt 40kg

[0098] Fruit powder 5kg DHA oil 5kg resistant dextrin 8kg

[0099] Iron pyrophosphate 0.6kg

[0100] Film raw material formula:

[0101] Modified starch 30kg Gelatin 10kg Gellan gum 1kg

[0102] Brown sugar 5kg glycerin 10kg purified water 34kg

[0103] Sugar alcohol 10kg

[0104] A method for making film-type functional chocolate, comprising the steps of:

[0105] 1) Preparation of chocolate sauce

[0106] According to the raw material formula of the chocolate sauce, first place 35kg of cocoa butter in a water bath at 50°C and heat to melt. Then sugar alcohol and fruit powder (blueberry powder) are pulverized, and the particle size can pass through a 300-mesh sieve for subsequent use. When the cocoa butter is completely melted, add 40kg of milk mineral salt, 6.4kg of sugar alcohol, 5kg of fruit powder (blueberry powder), 8kg of resistant dextrin, 0.6kg of ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com