Method for producing high-quality reconstituted tobacco according to improved papermaking technique

A reconstituted tobacco leaf, high-quality technology, applied in the direction of tobacco, tobacco preparation, application, etc., to achieve the effect of improving extraction efficiency, covering thoroughly, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0043] A method of improving the papermaking method to produce high-quality recombined tobacco leaves. It first soaks the tobacco leaves and tobacco stems, then extracts the water-soluble substances with water, and after the solid-liquid separation, the solid part is pulped to make a paper base, while the liquid part is concentrated Finally, the enzyme is inactivated under high temperature conditions, and then after the reaction of adjusting the fragrance, it is obtained by back coating on the paper base.

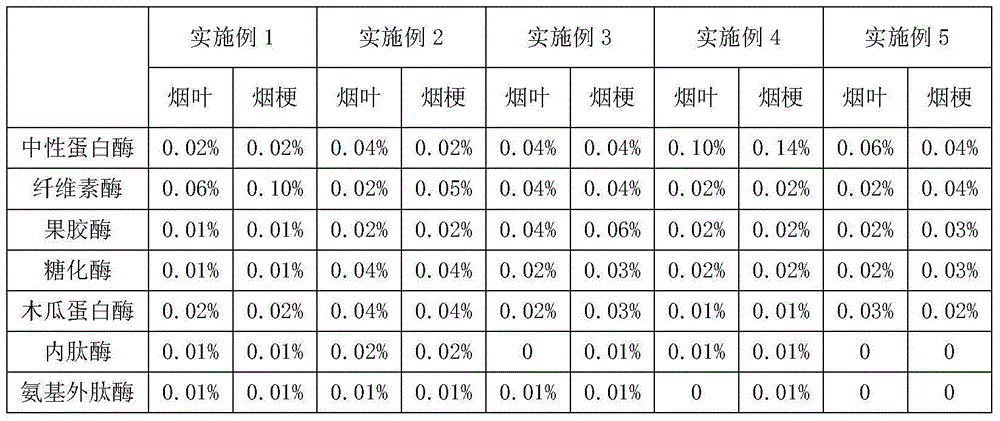

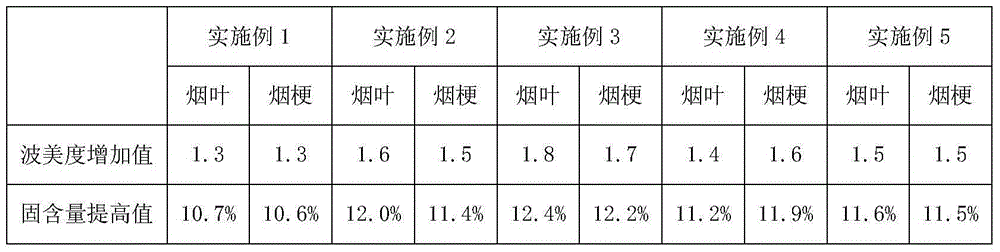

[0044] Mixed enzymes were added to the soaked tobacco leaves and tobacco stems respectively. Table 1 shows the weight percentage of the mixed enzymes in the raw materials of tobacco leaves and tobacco stems as described in Examples 1-5.

[0045]

[0046] Table 1 Mixed enzyme accounts for tobacco leaf raw material weight percentage and tobacco stem raw material weight percentage

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com