Sustained-released-type liquor aroma cigarette core line and preparation and application thereof

A slow-release, wine-flavored technology, applied in applications, e-liquid filters, tobacco, etc., can solve the problems of no improvement in the characteristic aroma and smoking quality of cigarettes, increase the moisturizing feeling of cigarettes, improve the tingling feeling, and improve the release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

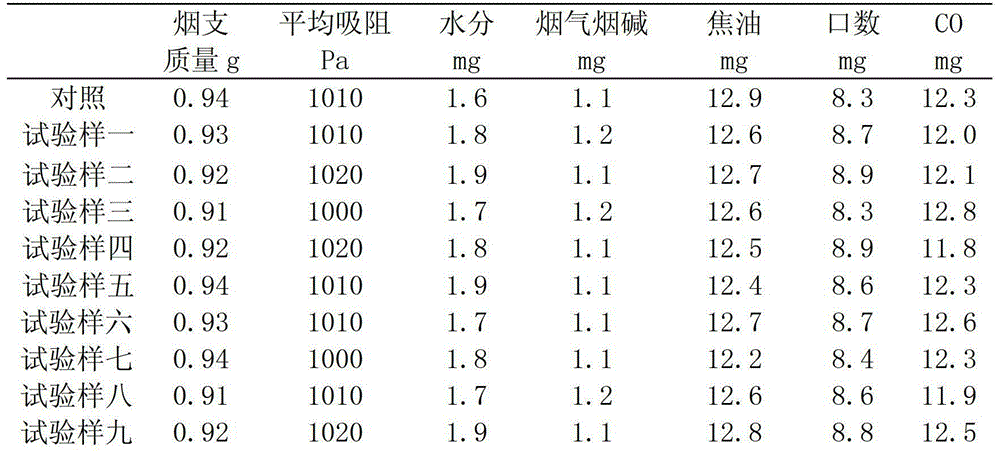

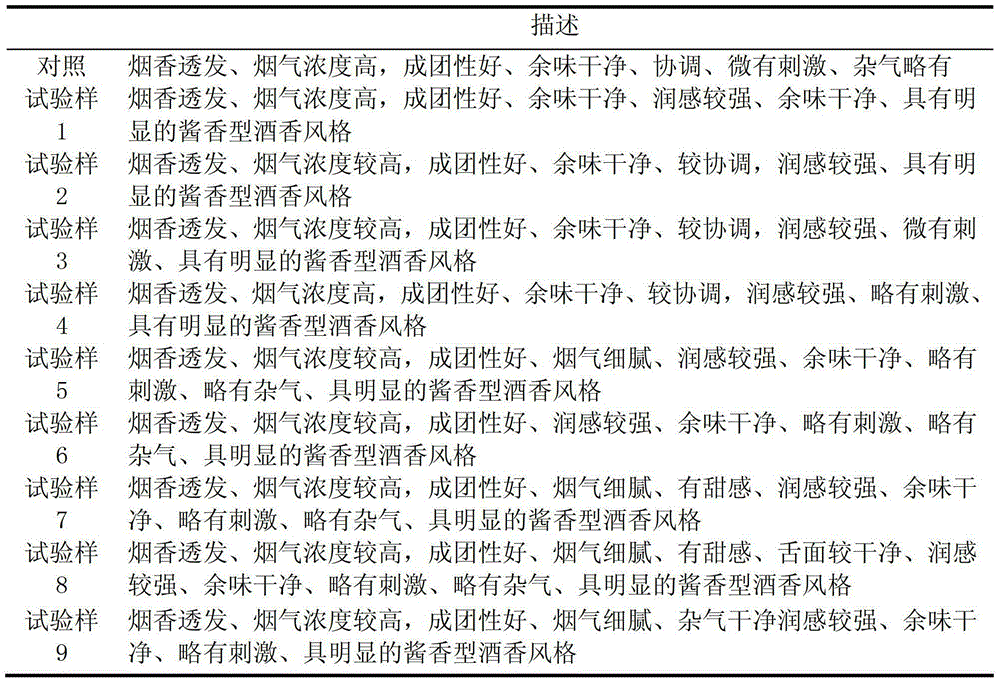

Examples

Embodiment 1

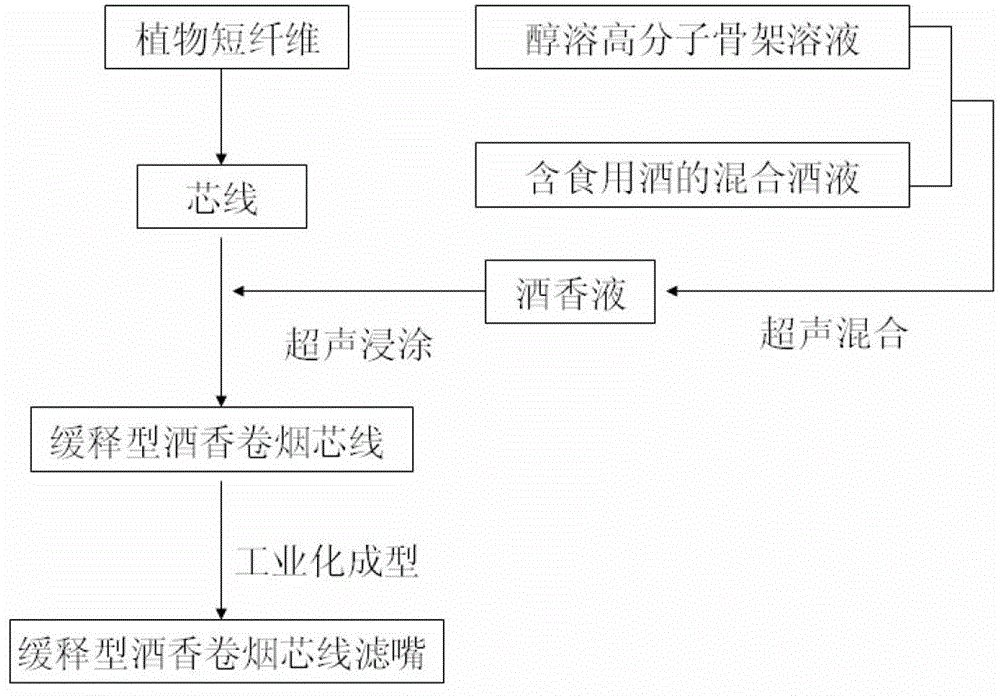

[0036] 1. Preparation of sustained-release liquor-flavored cigarette core wire

[0037] 1) Dissolving hydroxypropyl methylcellulose in ethanol solution to obtain a skeleton solution, the mass percentage of hydroxypropylmethylcellulose in the skeleton solution is 10wt%; dissolving Maotai wine in deionized water: ethanol weight ratio is In the 1:1 wetting agent, the mass ratio of Moutai to the wetting agent is 1:5 to obtain a mixed wine; add the skeleton solution to the mixed liquor, and the mass ratio of the skeleton solution to the mixed liquor is 2:1 , 20kHz ultrasonic mixing to obtain wine flavor liquid;

[0038] 2) Soybean short fiber and bamboo charcoal short fiber are spun into single yarn through the short fiber yarn forming system, and then 10 single yarns are combined and twisted to form strands, and finally 20 strands are further combined and twisted, get core wire;

[0039] 3) Continue to ultrasonically mix the wine aroma liquid in step 1), and place the core wire ...

Embodiment 2

[0045] 1. Preparation of sustained-release liquor-flavored cigarette core wire

[0046] 1) Dissolving hydroxypropyl methylcellulose in ethanol solution to obtain a skeleton solution, the mass percentage of hydroxypropylmethylcellulose in the skeleton solution is 20wt%; dissolving Moutai in deionized water: propylene glycol weight ratio is In the wetting agent of 1:2, the mass ratio of Maotai wine and wetting agent is 1:3, and the mixed wine is obtained; the skeleton solution is added to the mixed liquor, and the mass ratio of the skeleton solution to the mixed liquor is 10:1 , 60kHz ultrasonic mixing to obtain wine flavor liquid;

[0047] 2) Spin ramie staple fiber and bamboo charcoal staple fiber into single yarn, then combine and twist 40 single yarns to make strands, and finally combine and twist 4 strands to obtain core yarn;

[0048] 3) Continue to ultrasonically mix the wine aroma solution in step 1), and place the core wire prepared in step 2) in the wine aroma solutio...

Embodiment 3

[0053] 1. Preparation of sustained-release liquor-flavored cigarette core wire

[0054] 1) Dissolve ethyl cellulose in an ethanol solution to obtain a skeleton solution. The mass percentage of ethyl cellulose in the skeleton solution is 50wt%; dissolve Moutai wine in a wetting agent with a ratio of 1:1 of deionized water: propylene glycol , the mass ratio of Moutai and wetting agent is 1:10 to obtain the mixed liquor; add the skeleton solution to the mixed liquor, the mass ratio of the skeleton solution to the mixed liquor is 6:1, 80kHz ultrasonic mixing to obtain the aroma of the liquor liquid;

[0055] 2) Spin soybean staple fiber and tencel staple fiber into single yarn, then combine and twist 20 single yarns to form strands, and finally combine and twist 32 strands to obtain core yarn;

[0056] 3) Continue to ultrasonically mix the wine fragrance solution in step 1), and place the core wire prepared in step 2) in the wine fragrance solution in ultrasonic mixing for ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com