Regeneration method of silica gel bleaching sand for petroleum or animal and vegetable oil refining

A technology of animal and vegetable oils and decolorized sand, which is applied in the petroleum industry, separation methods, filter regeneration, etc., can solve the problems of destroying the structure of silica gel decolorized sand, poor quality, and deactivation of white clay, so as to improve the operating environment and reduce labor intensity , to solve the effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

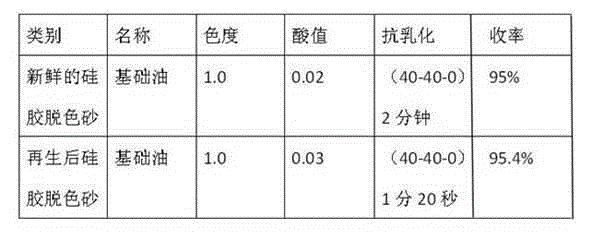

Examples

example 1

[0026] Example 1: One-time extraction: (1) Add 500ml of waste silica gel decolorizing sand to be processed into the extraction reaction kettle, and replace it with nitrogen for 3 times, then add 500ml of non-polar solvent SHD30 solvent oil into the extraction kettle at a temperature of 40 ℃, stirred for 15 minutes, after the stirring was completed, nitrogen pressure was filtered, and the pressure was controlled at 0.15Mpa. That is, 100 grams of waste silica gel decolorizing sand can extract 30 grams of oil), which is the first extraction; add 500 ml of mixed solution to the extraction reaction kettle, and the mixed solution is composed of 70% No. 120 solvent oil, 30% n-butyl acetate Ester, control the temperature at 40°C, stir for 40 minutes, the filtrate contains 7% oil, that is, 100 grams of waste silica gel decolorization sand can extract 7 grams of oil, the filtrate is dark red, filtered and dried, and the regeneration is completed.

example 2

[0027] Example 2: One-time extraction: (1) Add 600ml of waste silica gel decolorizing sand to be processed into the extraction reaction kettle, fill with nitrogen for 3 times, add 600ml of non-polar solvent 120 solvent oil into the extraction kettle, and the temperature is 40 ℃, stirred for 15 minutes, after the stirring was completed, nitrogen pressure was filtered, and the pressure was controlled at 0.15Mpa. That is, 100 grams of waste silica gel decolorizing sand can extract 25 grams of oil), which is the first extraction; add 600 ml of mixed solution to the extraction reaction kettle, and the mixed solution is composed of 70% SHD30 solvent oil, 30% n-butyl acetate Ester, control the temperature at 45°C, stir for 40 minutes, the filtrate contains 8% oil, that is, 100 grams of waste silica gel decolorization sand can extract 7 grams of oil, the filtrate color is dark red, filtered and dried, and the regeneration is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com