Catalyst for producing low-carbon olefins through efficient conversion of CO2

A low-carbon olefin and catalyst technology, which is applied in the field of catalysts for the efficient conversion of CO2 to low-carbon olefins, can solve the problems of high catalyst preparation cost, reduced selectivity of low-carbon olefins, low low-carbon olefins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

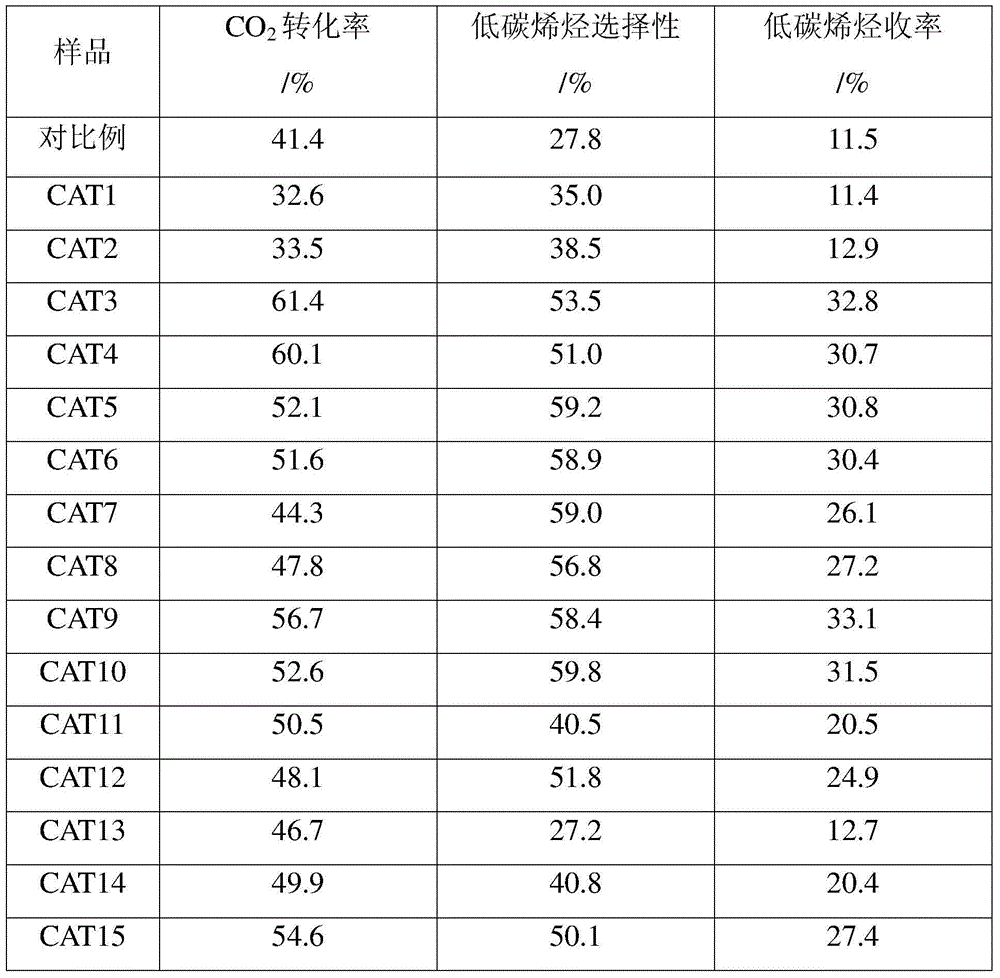

Examples

preparation example Construction

[0030] The preparation method of the catalyst provided by the present invention is mainly divided into two types: precipitation method and mechanical mixing method. Methods such as impregnation modification of alkali metals, alkaline earth metals and active Fe components are not excluded. The prepared catalyst precursor needs to be prepared before the reaction. Reduction, passivation and activation steps.

[0031] The structural formula of the catalyst of the present invention can be expressed as A-(B(C x Fe y )O z )-Fe / S, wherein x+y=2, z=3.2-4.2. A is an alkali metal or alkaline earth metal element (Na, K, Rb, Cs, Mg, Ca, Sr, Ba), B is a divalent ion of a transition metal element (Cr, Fe, Ni, Co, Cu, Zn, etc.), C is a trivalent ion of a transition metal element (Cr, Fe, Co, etc.); S is a carrier, and an oxide (Al 2 o 3 , SiO 2 , ZrO 2 etc.) or molecular sieves (Silicalite-1, ZSM-5, β molecular sieves, etc.). Catalysts for CO 2 Hydrogenation reaction to obtain linear...

Embodiment 1

[0053] Catalysts were prepared according to method one.

[0054] (1) Weigh 17.90g ZrO 2 solid, added to 100mL containing 0.22mol / L Fe(NO 3 ) 3 And 0.045mol / L KNO 3 solution, stir well and set aside.

[0055] (2) Weigh 1.44g FeSO 4 ·7H 2 O and 1.02g Fe(NO 3 ) 3 ·6H 2O, add it into 100mL water and stir well, raise the temperature to 358K under the protection of nitrogen, then slowly add 0.1mol / L NaOH solution for precipitation, after sufficient precipitation, cool down to room temperature, and pass in pure air for aging for 12h. Then add the suspension prepared in step (1), stir well, then dry the obtained suspension at 353K until there is no obvious moisture, further dry at 393K for 12h under nitrogen atmosphere, and then calcinate at 773K for 5h.

[0056] (3) The catalyst sample obtained in step (2) is compressed at 20 MPa, sieves 20 to 40 mesh particles, weighs 10.0 g, and reduces 5 h at 673 K with a hydrogen stream (nitrogen containing 5% hydrogen). After reaching ...

Embodiment 2

[0058] Weigh 38.84g ZrO(NO 3 ) 2 2H 2 O, added to 100mL containing 0.22mol / L Fe(NO 3 ) 3 And 0.045mol / L KNO 3 solution, stir well and set aside. Subsequent steps are the same as in Example 1, and the catalyst obtained is denoted as CAT2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com