A kind of novel green solid superacid catalyst and application thereof for self-condensation reaction of cyclohexanone

A technology of solid super acid and cyclohexanone, applied in the field of catalysis, can solve the problems of difficult disposal of waste liquid, low dimer yield and increased reaction yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

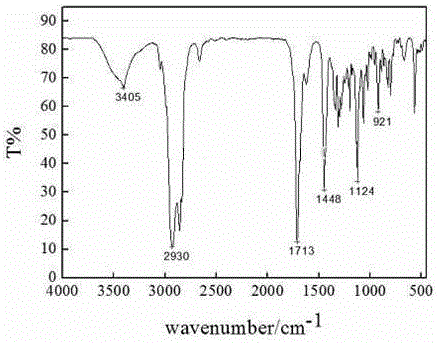

Image

Examples

Embodiment 1

[0033] Embodiment 1: first 1gLa (NO 3 ) 3 ·6H 2 O, 1gCe (NO 3 ) 3 ·6H2 O, 100g (NH 4 ) 2 SO 4 Dissolve in distilled water, then put 10g nanometer ZrO 2 , impregnated at 20°C for 36h, dried to anhydrous, and calcined at 550°C for 5h to obtain the catalyst SO 4 2- ·xLa 3+ ·yCe 3+ / zZrO 2 . Add 1.3L of cyclohexanone into a 2L reaction flask, add the prepared catalyst to be 5% of the quality of cyclohexanone, react at 160°C for 2.5h, analyze the reaction solution by gas chromatography to obtain a conversion rate of cyclohexanone of 85%, Dimer selectivity was 96.5%.

Embodiment 2

[0034] Embodiment 2: earlier 2gLa (NO 3 ) 3 ·6H 2 O, 2gCe (NO 3 ) 3 ·6H 2 O, 100g (NH 4 ) 2 SO 4 Dissolve in distilled water, then put 25g nanometer ZrO 2 , impregnated at 20°C for 36h, dried to anhydrous, and calcined at 550°C for 5h to obtain the catalyst SO 4 2- ·xLa 3+ ·yCe 3+ / zZrO 2 . Add 1.3L cyclohexanone into a 2L reaction flask, add the prepared catalyst to be 5% of the quality of cyclohexanone, react at 160°C for 2.5h, analyze the reaction solution by gas chromatography, and obtain a conversion rate of cyclohexanone of 93.2%. Dimer selectivity was 97.1%.

Embodiment 3

[0035] Embodiment 3: first with 5gLa (NO 3 ) 3 ·6H 2 O, 5gCe (NO 3 ) 3 ·6H 2 O, 100g (NH 4 ) 2 SO 4 Dissolve in distilled water, then put 100g nano ZrO 2 , impregnated at 20°C for 36h, dried to anhydrous, and calcined at 550°C for 5h to obtain the catalyst SO 4 2- ·xLa 3+ ·yCe 3+ / zZrO 2 . Add 1.3L cyclohexanone into a 2L reaction flask, add the prepared catalyst to be 5% of the quality of cyclohexanone, react at 160°C for 2.5h, analyze the reaction solution by gas chromatography to obtain a conversion rate of cyclohexanone of 98.3%, Dimer selectivity was 98.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com