Casting mold and method for planet carrier for jack-up offshore platform lifting gear box

An offshore platform and self-elevating technology, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of complex manufacturing process, easy damage, unfavorable welding, etc., to improve the ability of damage resistance, repair The shrinkage channel is smooth and the effect of eliminating crack defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

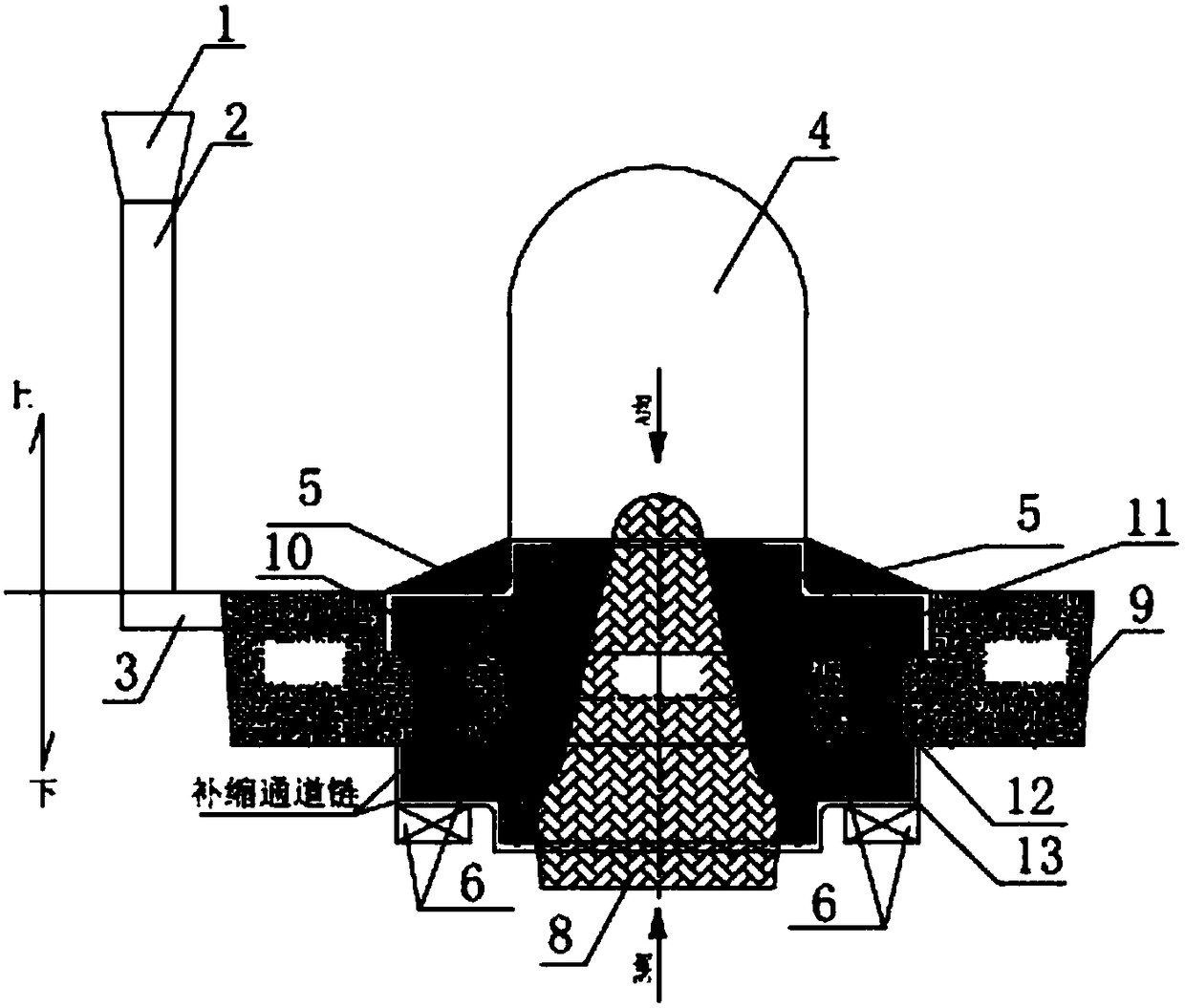

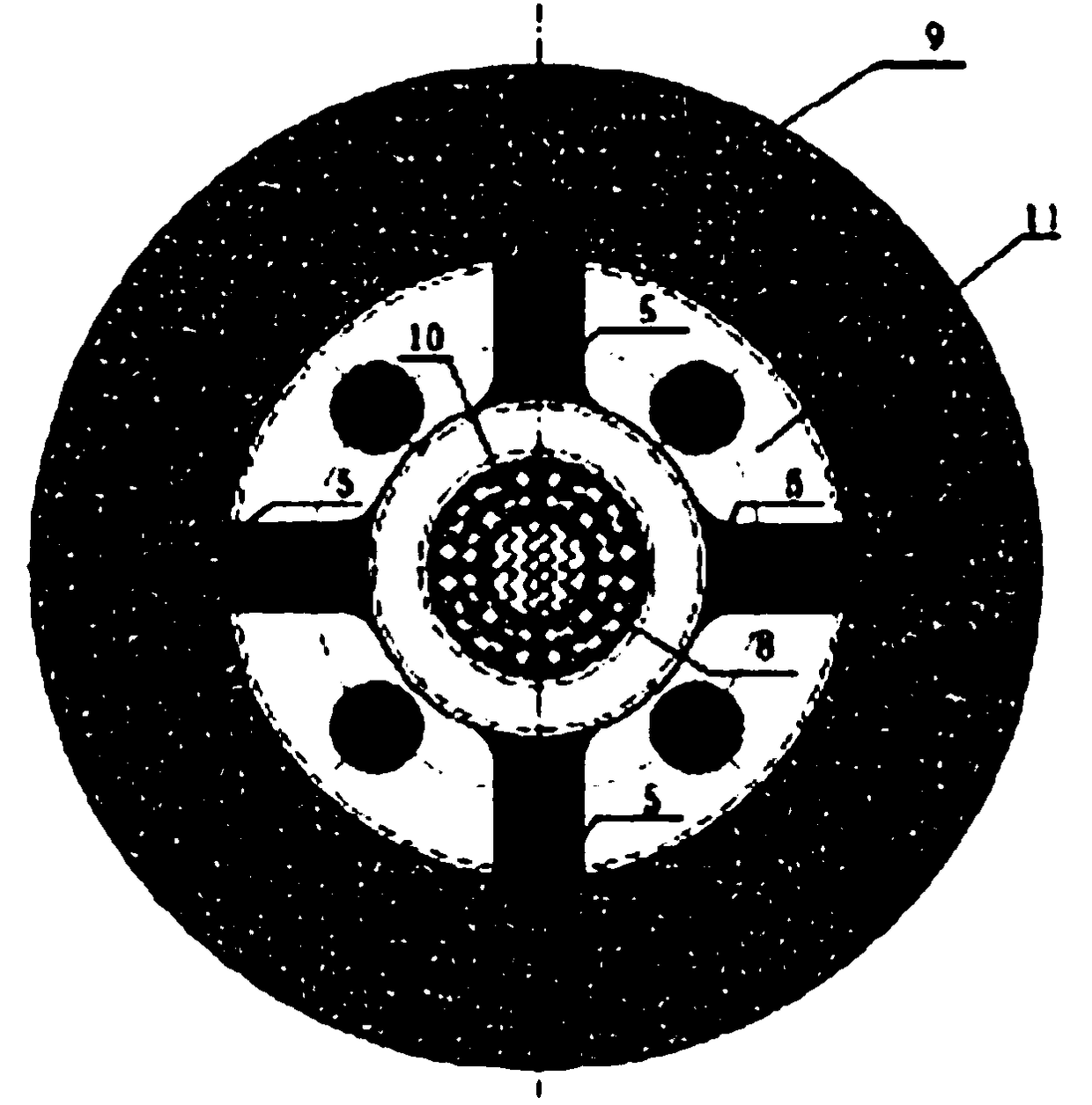

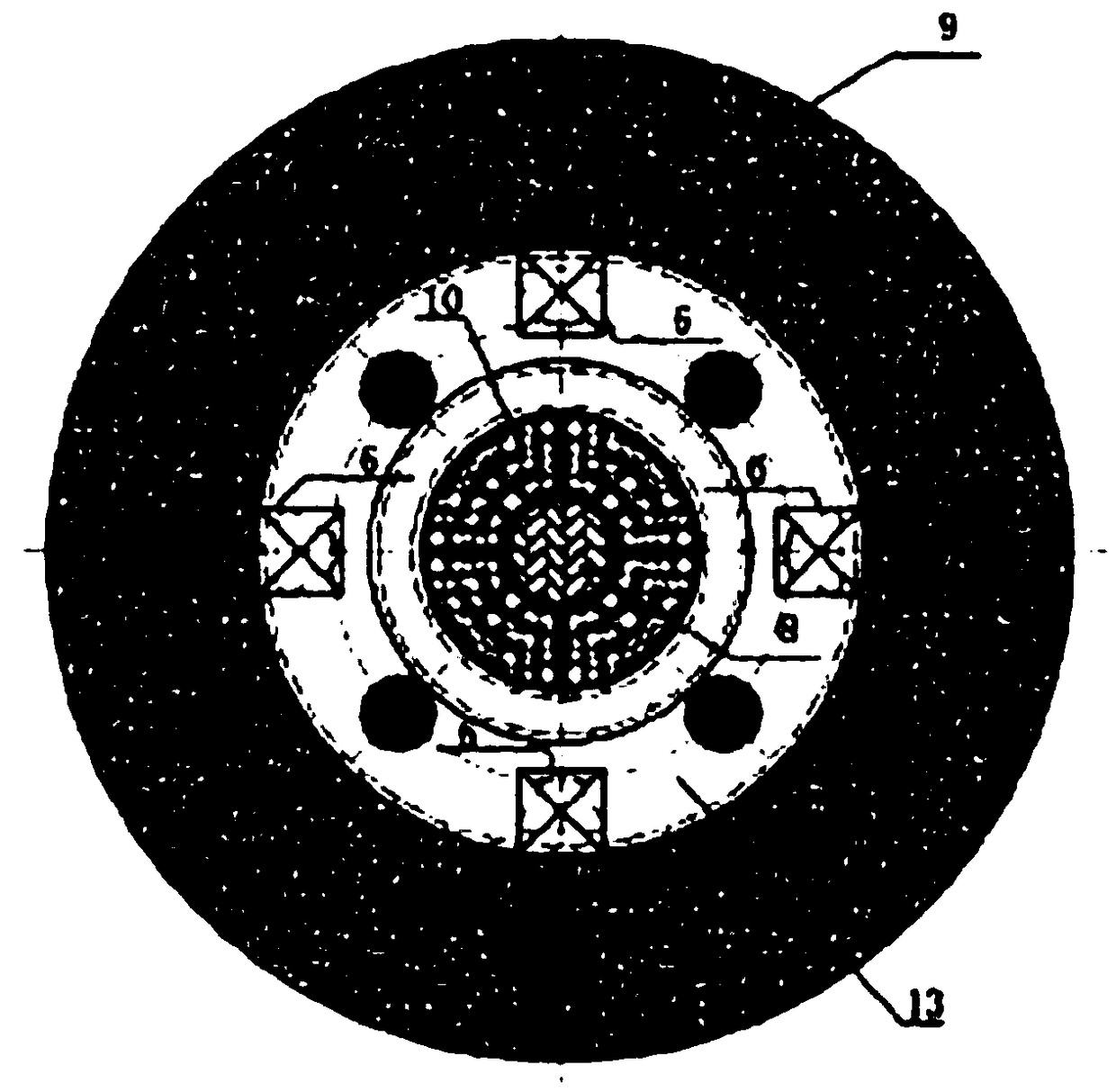

[0026] Embodiment 1: with reference to attached Figure 1-3. A casting die for a planet carrier with a large speed ratio and super high torque self-elevating offshore platform lifting gearbox. There are four wedge-shaped subsidies 5 at the positions of the four pins in the area of the upper flange 11 and together with the upper flange 11. It constitutes a movable block, which is inlaid in the upper middle of the core head 9 round table, four pins 12, the main feeding channel subsidy 10 and the connection area with the upper flange 11 and the lower flange 13 and covers the center core head 8, the core The head 9 is integrally formed with the upper and lower flanges and the central core head 8. The central core head 8 is a tapered cylinder with a small upper part and a larger lower part. Above the upper flange 11 is an insulation riser 4 . There is an ingate 3 on the side of the core head 9, the ingate 3 communicates with the sprue 2, and the sprue cup 1 is located at the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com