Manufacturing method of TA6 titanium alloy large-width thin plate

A titanium alloy and sheet technology, which is applied in the field of preparation of TA6 titanium alloy wide sheet, can solve the problems of unsuitable TA6 titanium alloy wide sheet, unstable product performance index, uneven structure, etc., so as to avoid surface or internal cracking , The effect of reducing internal defects and uniform organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

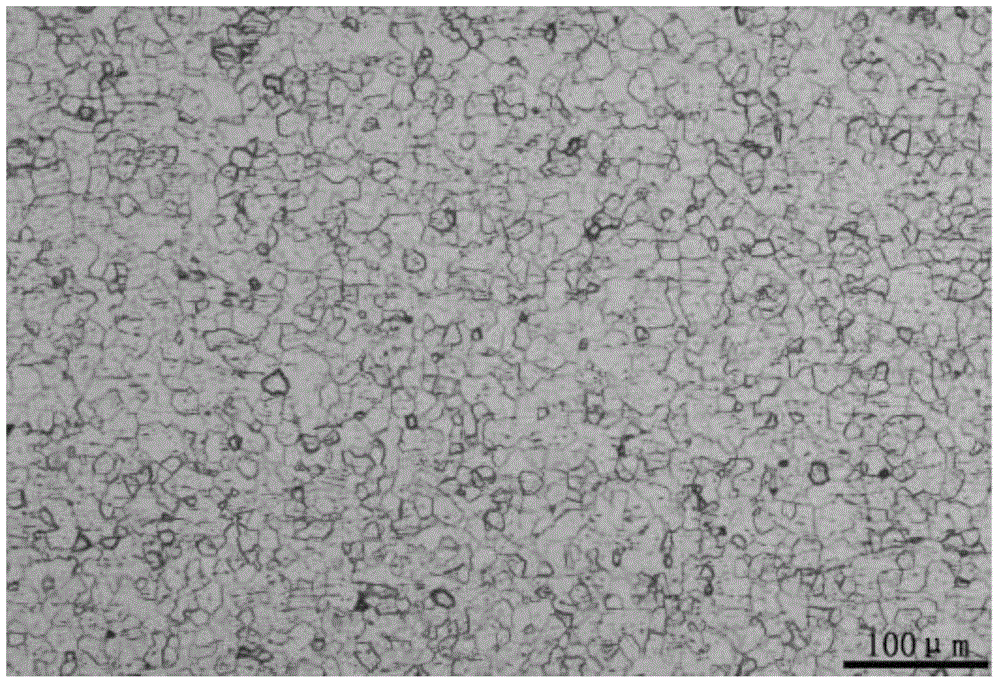

Embodiment 1

[0036] The method for preparing TA6 titanium alloy wide sheet in this embodiment comprises the following steps:

[0037] Step 1. Explosively compound a layer of pure titanium plate on the upper and lower surfaces of the TA6 titanium alloy plate with a thickness of 180 mm, a width of 1000 mm, and a length of 1200 mm to obtain a composite plate; the thickness of the pure titanium plate is 1.0 mm, and the width is 1030 cm. The length is 1230cm, and the grade of the pure titanium plate is TA1;

[0038] Step 2. Place the composite plate described in step 1 in a pusher-type natural gas heating furnace, and heat it for 200 minutes at a temperature of 70° C. above the β phase transition point of the TA6 titanium alloy for the first heat treatment;

[0039] Step 3. Send the composite plate after the first heat treatment in step 1 into a 2800mm hot rolling mill, and carry out the first fire rolling under the condition of the final rolling temperature of 920°C to obtain a thickness of 45...

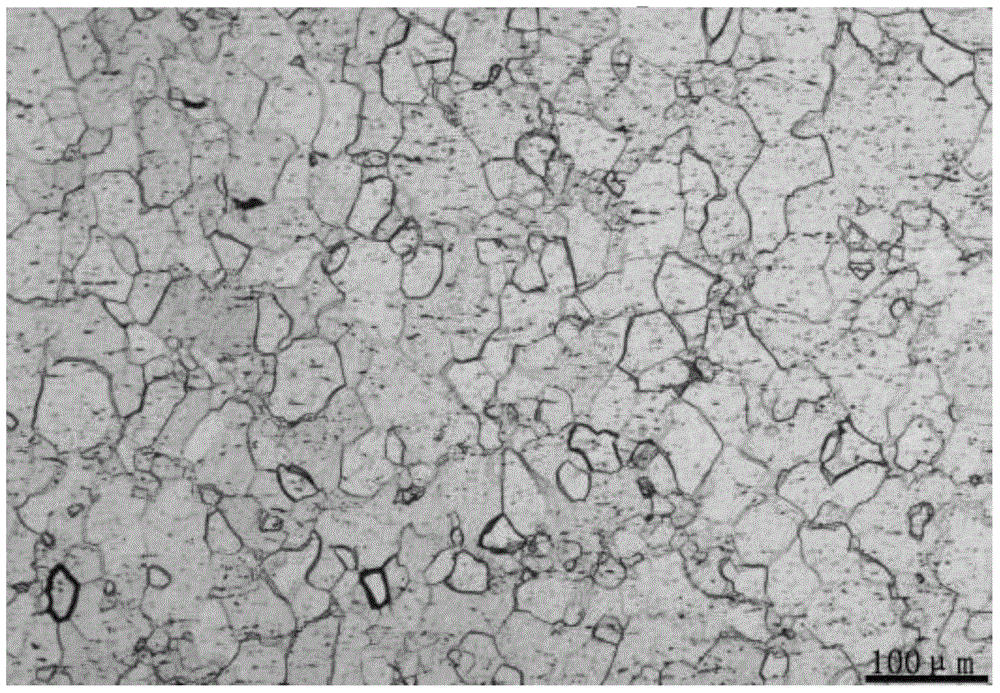

Embodiment 2

[0053] The method for preparing TA6 titanium alloy wide sheet in this embodiment comprises the following steps:

[0054] Step 1. Explosively compound a layer of pure titanium plate on the upper and lower surfaces of the TA6 titanium alloy plate with a thickness of 150mm, a width of 1200mm, and a length of 1200mm to obtain a composite plate; the thickness of the pure titanium plate is 0.8mm, and the width is 1220cm. The length is 1220cm, and the grade of the pure titanium plate is TA2;

[0055] Step 2, placing the composite plate described in step 1 in a pusher-type natural gas heating furnace, and performing the first heat treatment at a temperature of 50°C above the β phase transition point of the TA6 titanium alloy for 180 minutes;

[0056] Step 3. Send the composite plate after the first heat treatment in step 1 into a 2800mm hot rolling mill, and carry out the first fire rolling under the condition of the final rolling temperature of 910°C to obtain a thickness of 40mm and...

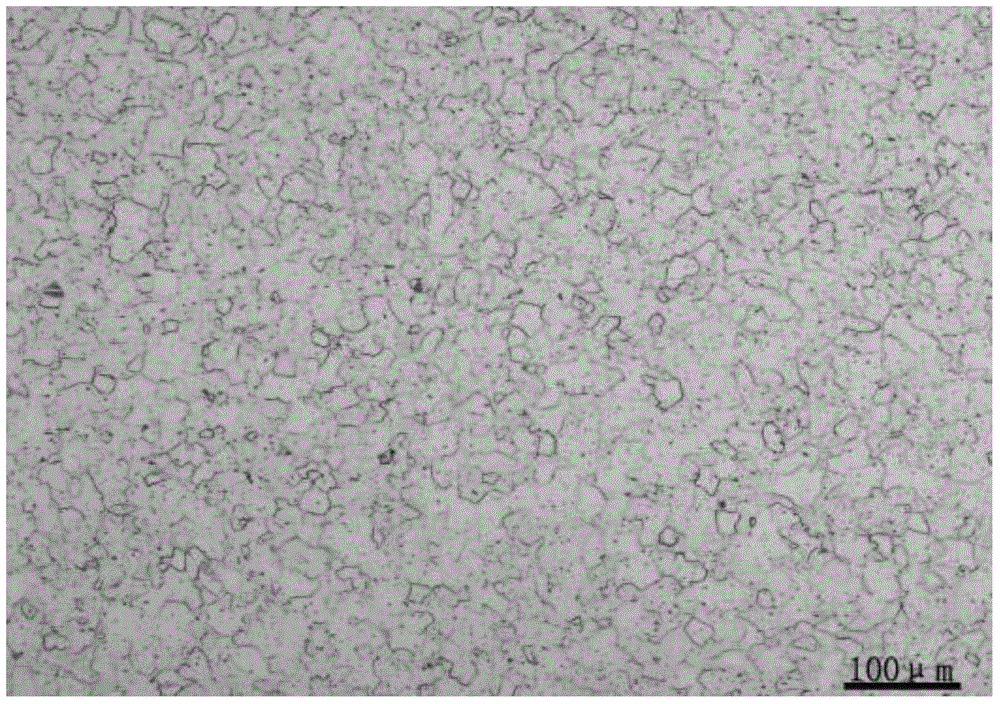

Embodiment 3

[0070] The method for preparing TA6 titanium alloy wide sheet in this embodiment comprises the following steps:

[0071] Step 1. Explosively compound a layer of pure titanium plate on the upper and lower surfaces of the TA6 titanium alloy plate with a thickness of 200mm, a width of 1200mm, and a length of 1500mm to obtain a composite plate; the thickness of the pure titanium plate is 1.0mm, and the width is 1225cm. The length is 1525cm, and the grade of the pure titanium plate is TA2;

[0072] Step 2. Place the composite plate described in step 1 in a pusher-type natural gas heating furnace, and carry out the first heat treatment at a temperature of 100°C above the β phase transition point of the TA6 titanium alloy for 240 minutes;

[0073] Step 3. Send the composite plate after the first heat treatment in step 1 into a 2800mm hot rolling mill, and perform the first fire rolling under the condition of the final rolling temperature of 910°C to obtain a thickness of 50mm and a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com