Method for measuring temperature of polymer melt on screw rod surface

A melt temperature and polymer technology, applied in the field of mechanization and chemical industry, can solve the problems of complex data acquisition system, increase the complexity of experimental system or production equipment, etc., and achieve the effect of expanding the measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

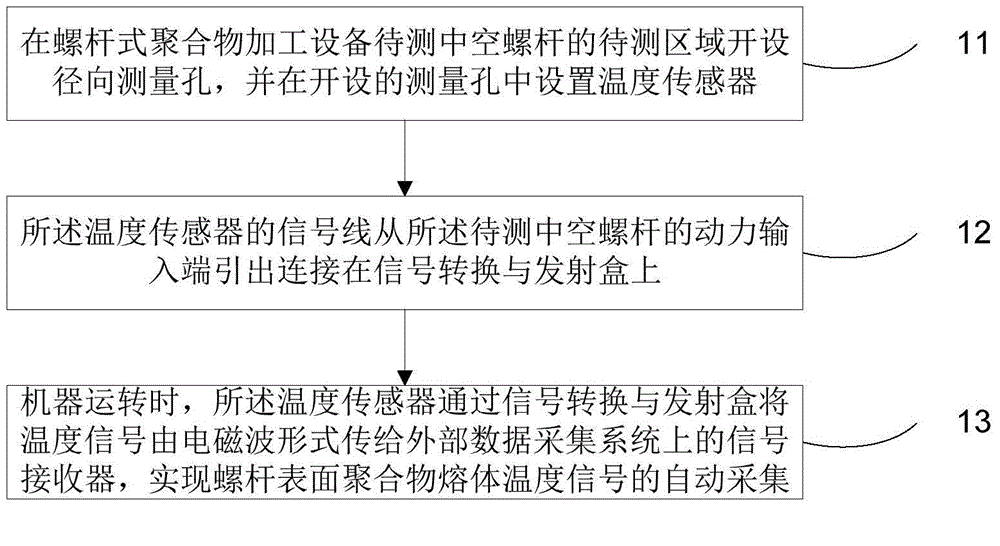

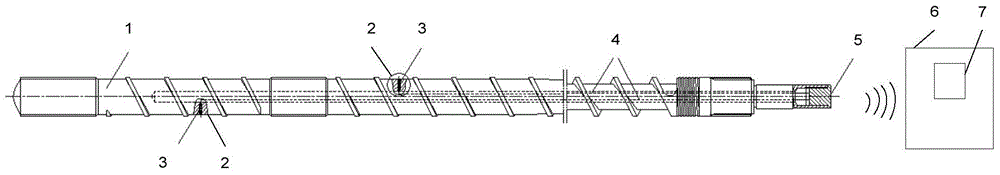

[0025] figure 1 It is a flowchart of a method for measuring the polymer melt temperature on the surface of a screw provided in Example 1 of the present invention. Such as figure 1 As shown, the method mainly includes the following steps:

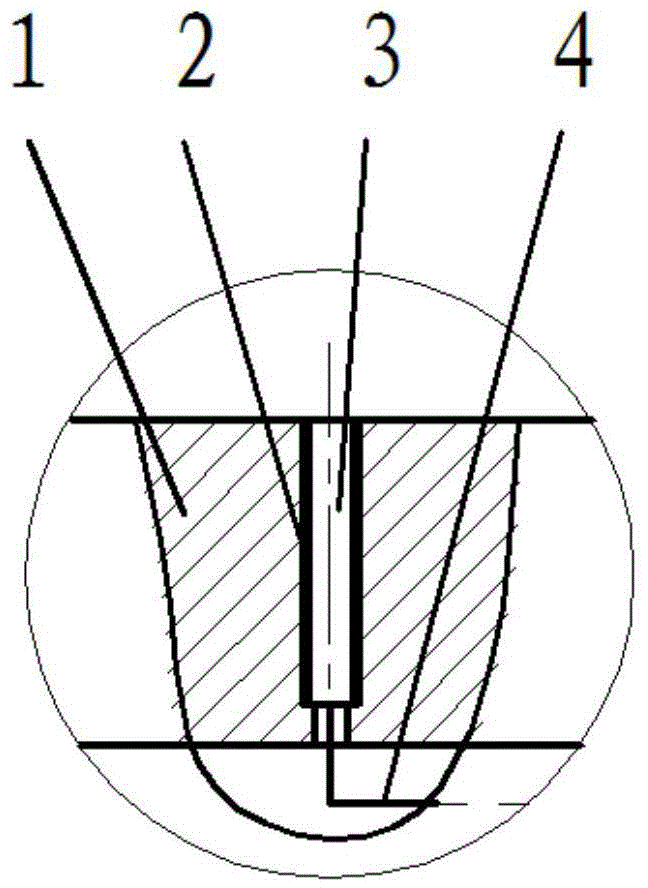

[0026] Step 11: Open a radial measuring hole in the area to be tested of the hollow screw of the screw-type polymer processing equipment to be tested, and set a temperature sensor in the opened measuring hole.

[0027] In the embodiment of the present invention, the screw-type polymer processing equipment is a polymer processing equipment with (hollow) screw elements, including: single-screw, twin-screw, multi-screw and planetary screw extruders, and twin-rotor continuous mixing machine and screw injection molding machine, etc.

[0028] The area to be tested on the hollow screw to be tested can be set on different functional elements of the hollow screw to be tested, including: a hollow screw conveying element, and functions such as melti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com