Energy absorption structure for corrugated sandwich panel

A technology of energy-absorbing structures and sandwich panels, which is applied to layered products, metal layered products, synthetic resin layered products, etc., can solve the problems of inability to effectively dissipate heat actively and uneven energy absorption of thin-walled tubes, etc. Achieve the effect of beautiful preparation, strong toughness and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments. However, it can be understood that the following specific embodiments are only preferred technical solutions of the present invention, and should not be understood as limiting the present invention.

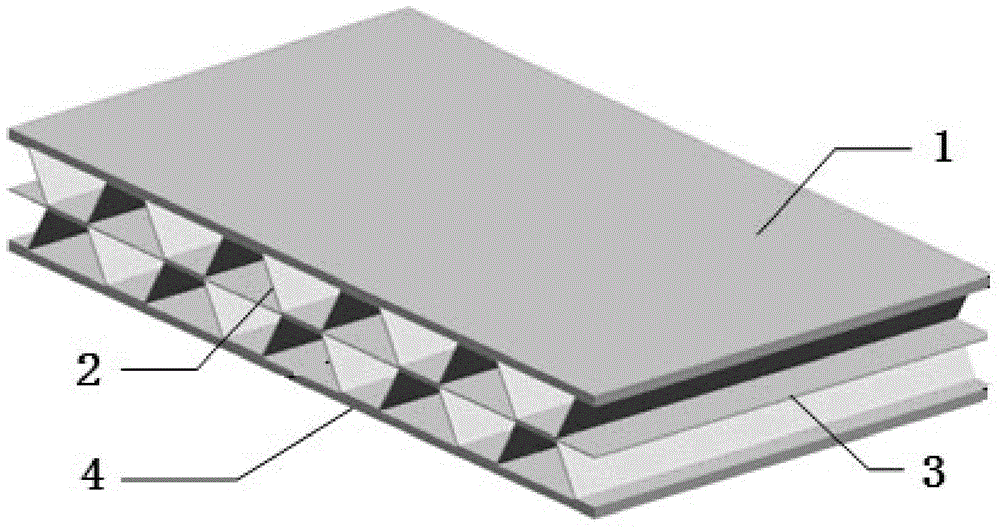

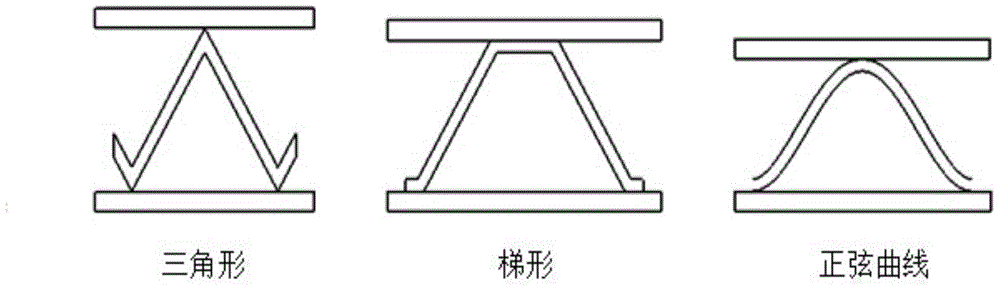

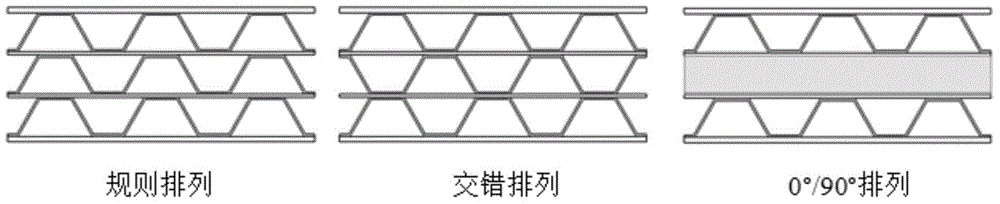

[0023] Such as figure 1 As shown, a corrugated sandwich panel energy absorbing structure, the energy absorbing structure is composed of an upper panel 1, a corrugated core 2, a sandwich panel 3 and a lower panel 4. Each part is stacked in sequence and glued by epoxy structural glue to form a whole structure The cross section of the corrugated core 2 is trapezoidal, the thickness of the upper panel 1 and the lower panel 4 is 0.5-1mm; the thickness of the sandwich panel 2 is 0.2-0.5mm; the thickness of the corrugated core 2 is 0.1-0.2mm, right-angled The side length is 0-7mm, the hypotenuse length is L 1 3-15mm, the angle ω between the corrugated core 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com