Method for preparing graphene through molten inorganic salt reaction bed

An inorganic salt and reaction bed technology, applied in the field of graphene material preparation, can solve the problems of high cost, poor compatibility, poor dispersion and the like, and achieve the effect of simple method and environmentally friendly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

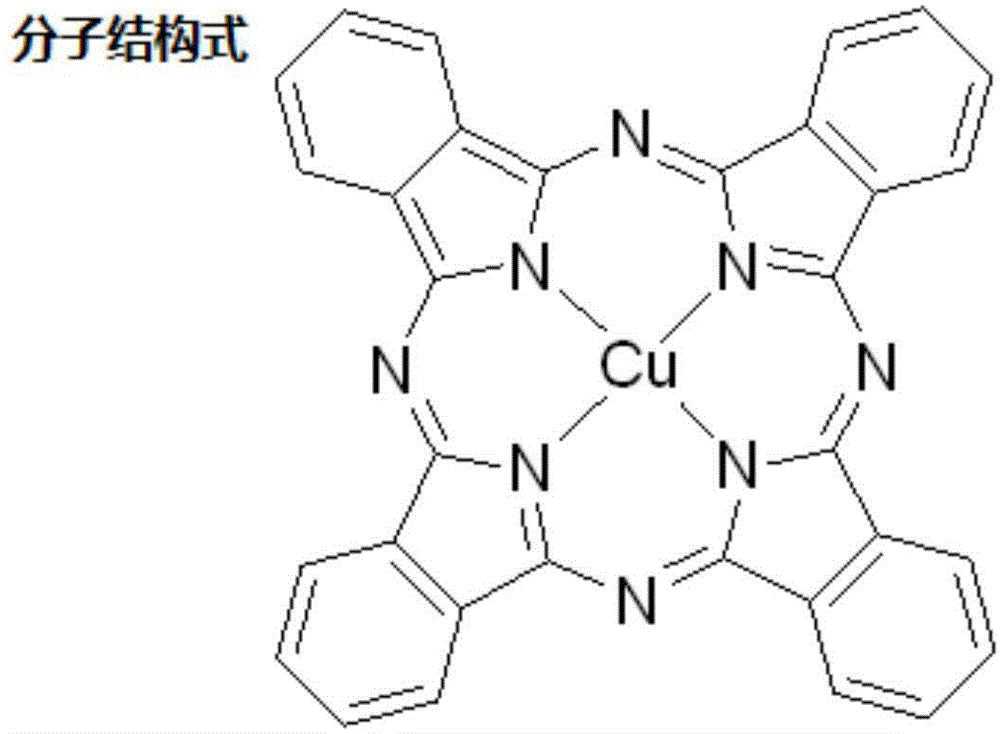

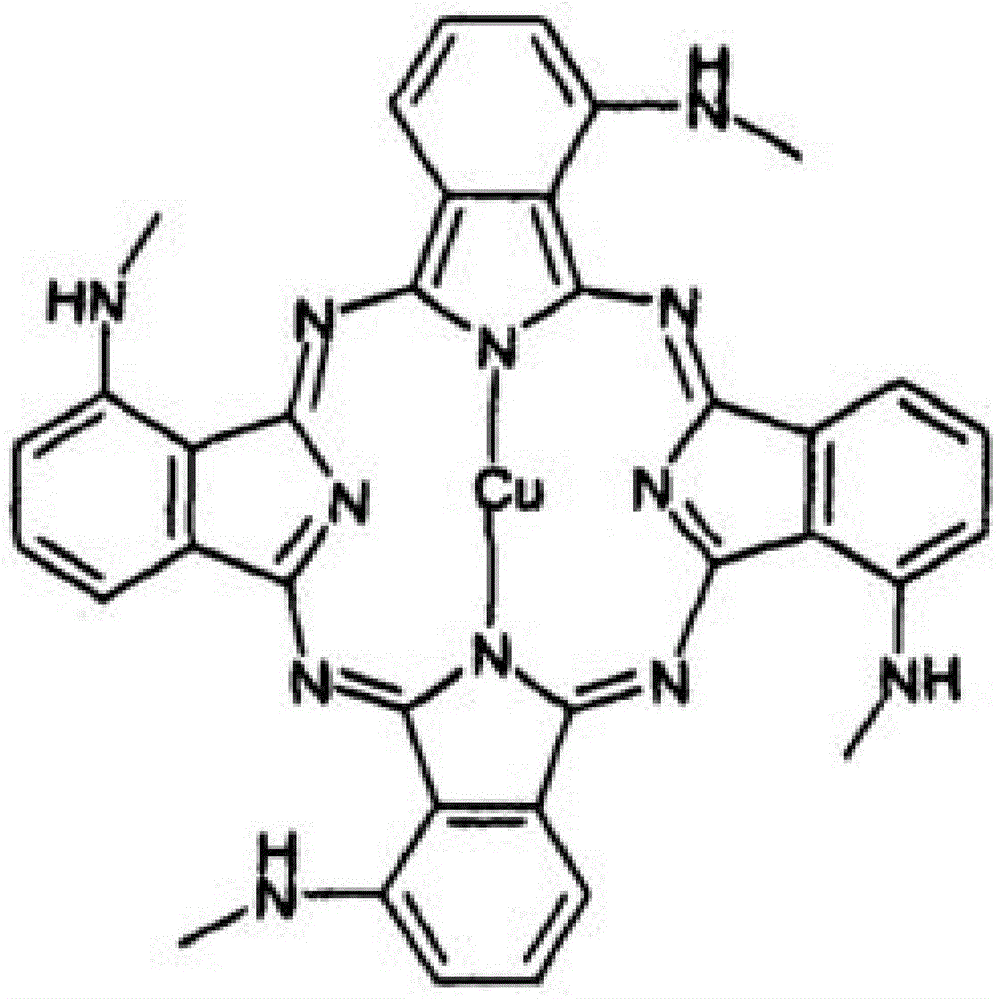

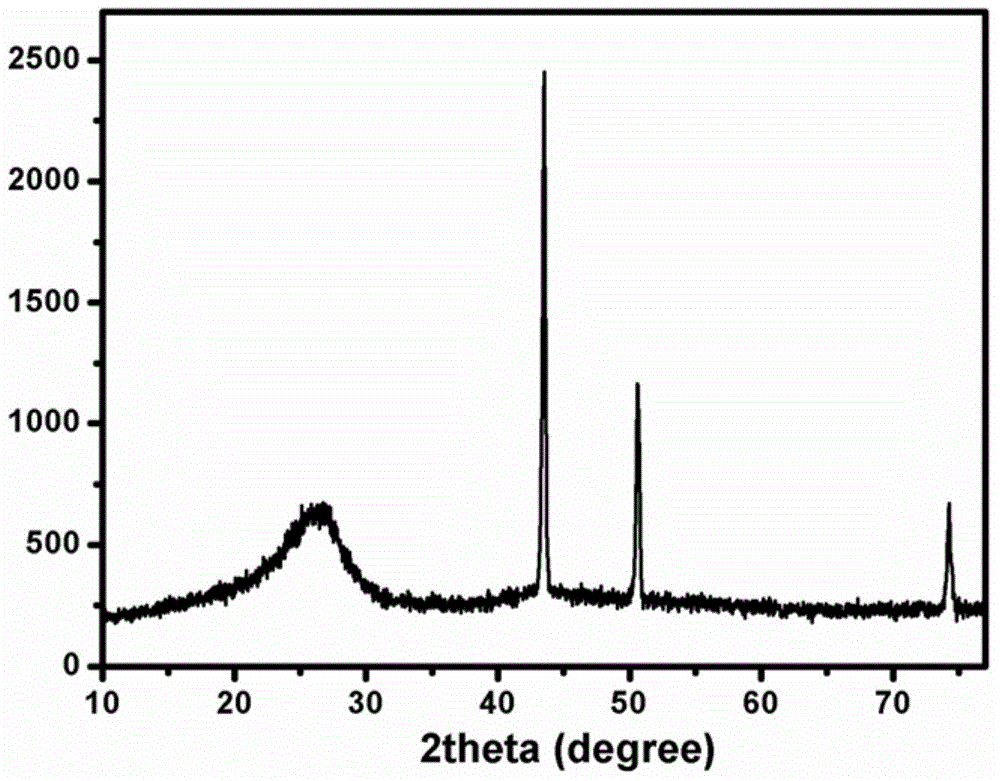

[0037] 30.0 g of commercially available copper phthalocyanine (CuPc) was used as a raw material without any purification treatment, and mixed evenly with sodium chloride, and the mass ratio of raw material to salt was 1:99. In a quartz tube furnace, under the protection of high-purity argon, the flow rate of argon is controlled at 50cm 3 min -1 , 20.7 grams of final metallic graphene-like materials were obtained by cracking under the following heating scheme. That is, the temperature is raised to 300 degrees at a slow heating rate of 5 degrees per minute, and 300 degrees is stable for 1 hour; the temperature is raised to 350 degrees at 5 degrees per minute, and 350 degrees is stable for 1 hour; hour; be heated up to 500 degrees at 3 degrees per minute, and stabilize at 500 degrees for 4 hours; be heated at 2 degrees per minute to 800 degrees, be stable at 800 degrees for 8 hours, and finally cool down to room temperature naturally, and the product is washed with water to remo...

Embodiment 2

[0039] 30.0 g of commercially available copper phthalocyanine (CuPc) was used as a raw material without any purification treatment, and mixed evenly with potassium chloride, and the mass ratio of raw material to salt was 1:99. In a quartz tube furnace, under the protection of high-purity argon, the flow rate of argon is controlled at 50cm 3 min -1 , 20.7 grams of final metallic graphene-like materials were obtained by cracking under the following heating scheme. That is, the temperature is raised to 300 degrees at a slow heating rate of 5 degrees per minute, and 300 degrees is stable for 1 hour; the temperature is raised to 350 degrees at 5 degrees per minute, and 350 degrees is stable for 1 hour; hour; be heated up to 500 degrees at 3 degrees per minute, and stabilize at 500 degrees for 4 hours; be heated at 2 degrees per minute to 800 degrees, be stable at 800 degrees for 8 hours, and finally cool down to room temperature naturally, and the product is washed with water to r...

Embodiment 3

[0041] 30.0 g of commercially available copper phthalocyanine (CuPc) was used as a raw material without any purification treatment, and mixed evenly with sodium chloride, and the mass ratio of raw material to salt was 10:90. In a quartz tube furnace, under the protection of high-purity argon, the flow rate of argon is controlled at 50cm 3 min -1 , 20.7 grams of final metallic graphene-like materials were obtained by cracking under the following heating scheme. That is, the temperature is raised to 300 degrees at a slow heating rate of 5 degrees per minute, and 300 degrees is stable for 1 hour; the temperature is raised to 350 degrees at 5 degrees per minute, and 350 degrees is stable for 1 hour; hour; be heated up to 500 degrees at 3 degrees per minute, and stabilize at 500 degrees for 4 hours; be heated at 2 degrees per minute to 800 degrees, be stable at 800 degrees for 8 hours, and finally cool down to room temperature naturally, and the product is washed with water to rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com