Furnace

A heating furnace and optical fiber technology, which is applied in glass manufacturing equipment, instruments, glass fiber drawing devices, etc., can solve problems such as adhesion, carbon fiber falling off of brushes, and fiber strength reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

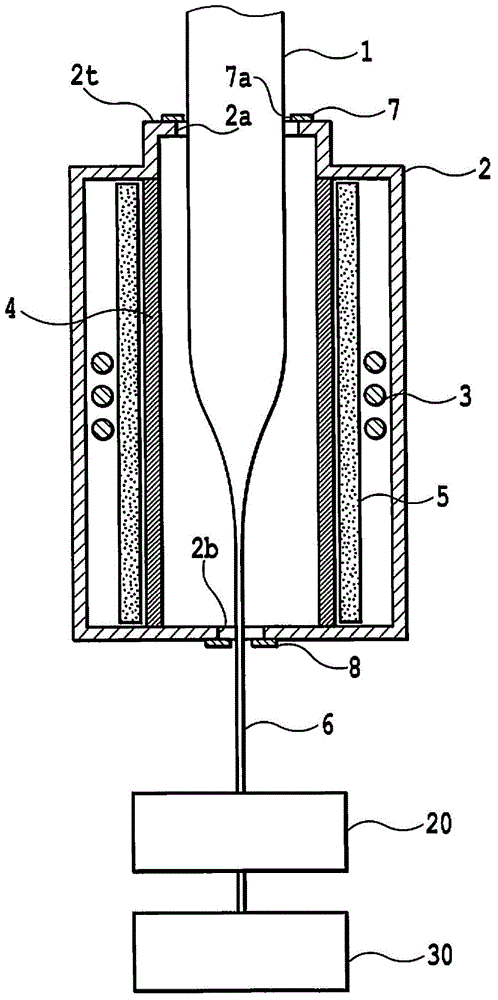

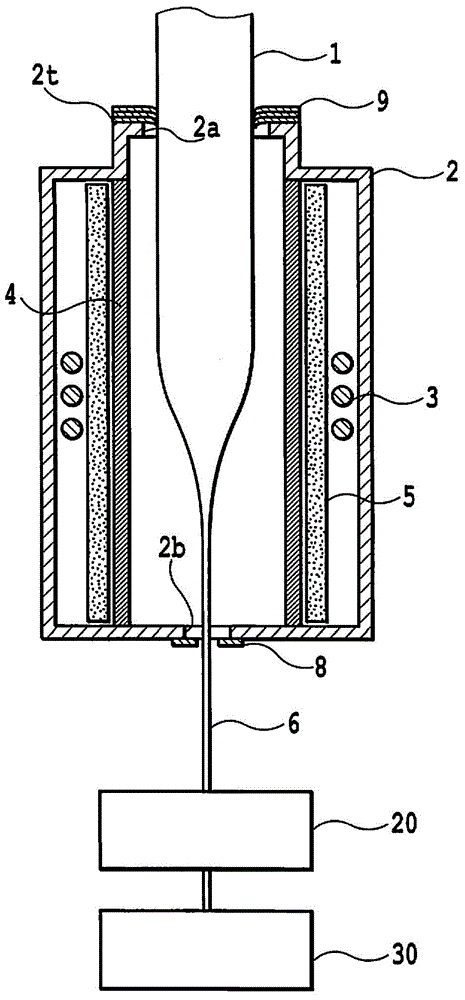

[0049] By using such as Figure 4 The shown heating furnace 2 heats ten glass preforms 1 having an average outer diameter of 64 mm, outer diameter fluctuations within ±2 mm, and a length of 1000 mm, and draws wires from the heated and melted ends of the glass preforms 1 optical fiber.

[0050] At the preform insertion port 2a of the heating furnace 2, ring-shaped sealing bodies produced under the following conditions were stacked.

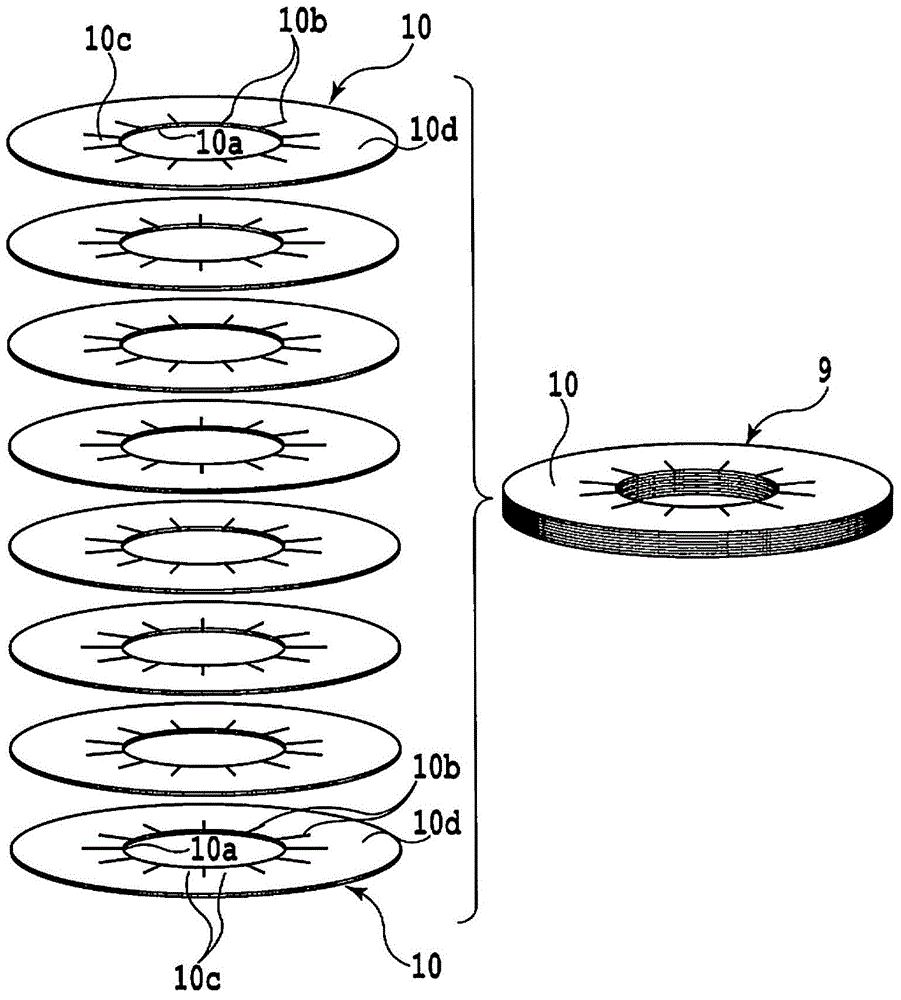

[0051] The annular disk 10 is made of a highly oriented pyrolytic graphite sheet with a thickness of 0.1 mm, and its insertion hole 10 a has a diameter of 60 mm. Twelve slits 10b having a length of 20 mm are formed in the annular disk 10 such that they extend radially from the inner edge of the insertion hole 10a of the annular disk 10 at angular intervals of 30° in the circumferential direction.

[0052] The annular sealing body 9 is formed by stacking eight annular disks 10 with the same structure, so that the adjacent annular disks are misalig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com