Manufacturing method of sanding-free burning-resistant superfine fireproof plate

A production method and technology of fireproof boards, which are applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as poor sales, rough outer surface, increased manufacturing time and labor costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The above and other technical features and advantages of the present invention will be described in more detail below with reference to the accompanying drawings and embodiments.

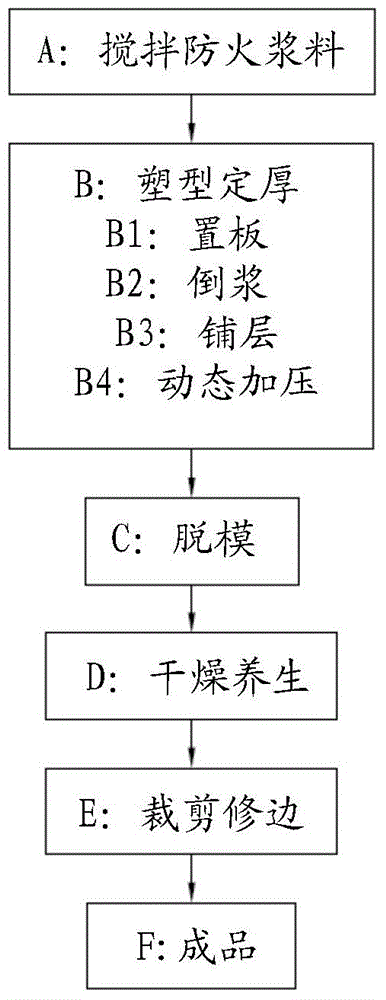

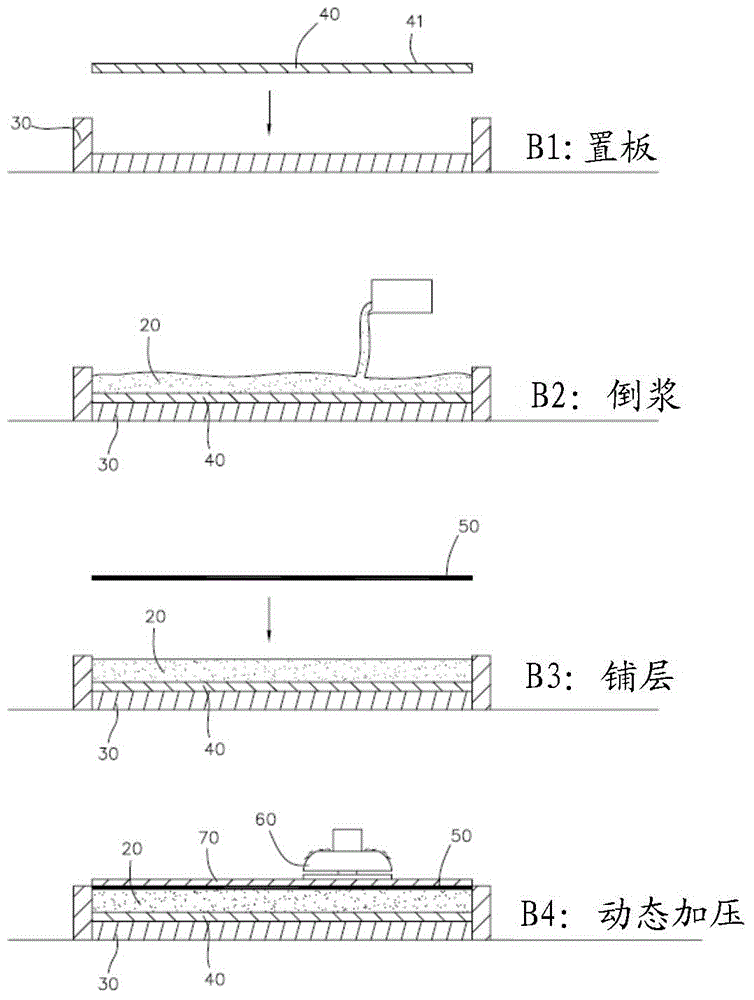

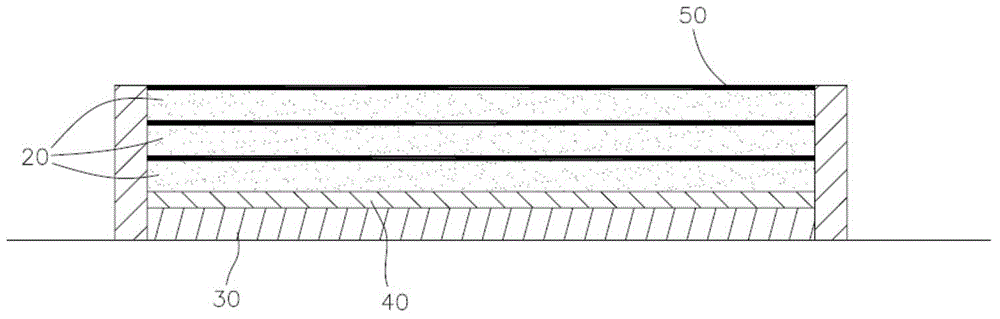

[0016] see Figure 1 to Figure 5 As shown, the manufacturing method of the non-sanding flame-resistant super-grade fireproof board of the present invention is applied to the manufacturing method of the fireproof board 10, especially a special manufacturing method that adds molding and thickness setting steps in the manufacturing process, so that the fireproof board 10 can be made After completion, its outer edge plate surface 11 can present a flat and smooth surface shape, and the articles and utensils required for making the fireproof board 10 include fireproof slurry 20, formwork 30, formwork 40, cladding layer 50 and pressurization equipment 60. The complete production method includes the following steps:

[0017] A: Stir the fireproof slurry 20, and stir the ingredients that make up the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com