Dispersant and method for improving magnetic property of permanent magnetic ferrite

A permanent magnet ferrite and magnetic performance technology, which is applied in the field of dispersant to improve the magnetic performance of permanent magnet ferrite, can solve problems such as difficult discharge, magnet cracking, and reduced efficiency and pass rate in the molding stage, so as to improve the use effect and increase Magnetic properties, the effect of excellent magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

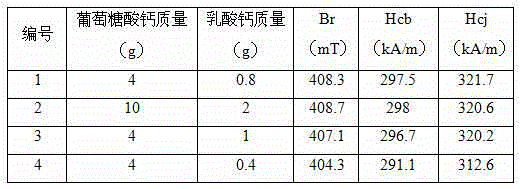

[0023] The dispersant in this example includes 4 experiments: wherein the mass ratios of calcium gluconate and calcium lactate are 5:1, 5:1, 4:1, and 10:1 in sequence.

[0024] The method for improving the magnetic performance of permanent ferrite comprises the following steps:

[0025] (1) Add 1kg of permanent magnet ferrite calcined material, 10g of calcium carbonate, 2.5g of quartz sand and 3g of alumina into the ball mill, then add 1.4kg of water, and then add dispersants (calcium gluconate and calcium lactate, please add See Table 1), start the ball mill until the particle size is 0.80 μm, and obtain the permanent magnet ferrite slurry; (2) precipitate and filter the permanent magnet ferrite slurry obtained in step (1) until the water content is 32wt%, and obtain the permanent magnet ferrite Filter the slurry; (3) inject the permanent magnet ferrite filter slurry obtained in step (2) into the mold, and pressurize at 380kg / cm under the condition of a magnetic field strengt...

Embodiment 2

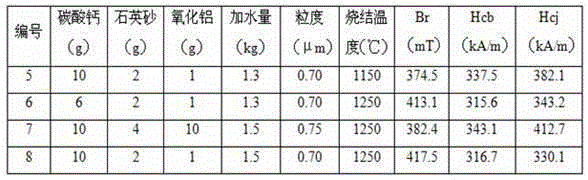

[0031] The mass ratio of the dispersant calcium gluconate and calcium lactate in this embodiment is 4:1.

[0032] The method for improving the magnetic performance of permanent ferrite comprises the following steps:

[0033] (1) Put 1kg of permanent magnet ferrite calcined material, calcium carbonate, quartz sand and alumina (see Table 2 for the amount added) into the ball mill, then add water (see Table 2 for the amount added), and then add the dispersant ( 4g calcium gluconate and 1g calcium lactate), start ball milling (see Table 2 for ball mill size), to obtain permanent ferrite slurry; (2) precipitate and filter the permanent ferrite slurry obtained in step (1) until the water content is 36wt%, to obtain the permanent magnet ferrite filter slurry; (3) inject the permanent magnet ferrite filter slurry obtained in step (2) into the mold, and pressurize 420kg / cm under the condition that the magnetic field strength is 780kA / m 2 Forming to obtain a permanent magnet ferrite gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com