Coating of water-based paint applied to engineering machinery product

A technology of construction machinery and water-based coatings, which is applied to the device for coating liquid on the surface, epoxy resin coatings, polyurea/polyurethane coatings, etc., to reduce coating costs, meet environmental protection requirements, and optimize comprehensive performance.

Inactive Publication Date: 2015-03-25

成都拜迪新材料有限公司

View PDF4 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the large construction machinery products and many parts, such as engineering tower cranes, there are many workpieces, so the scope of the spraying site is relatively large, and according to the requirements of the environmental protection department, general enterprises cannot invest more funds to rectify the painting site

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0012] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

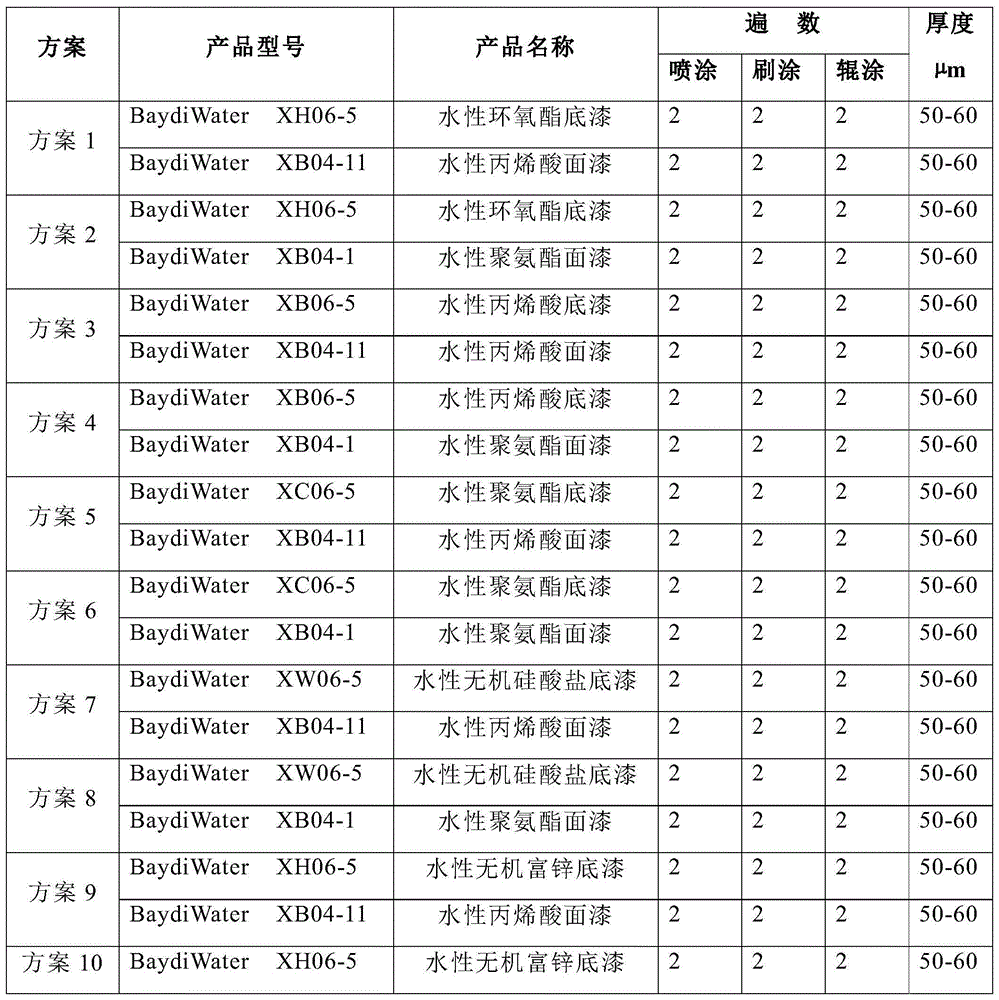

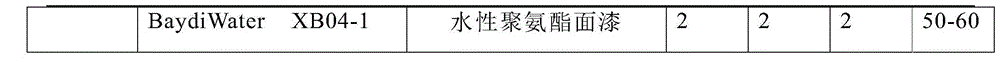

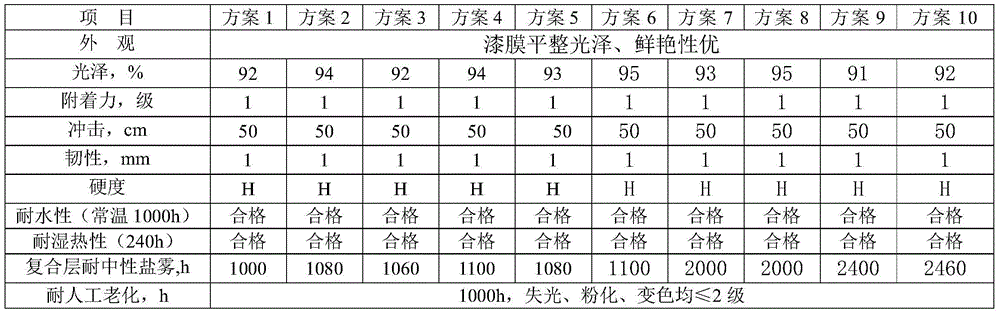

The invention provides coating of a water-based paint applied to an engineering machinery product; coating of the water-based paint provided by the invention comprises primers, intermediate paints and finishing paints; the primers comprise single-component primers and double-component primers; the single-component primers comprise a water-based epoxy ester primer, a water-based acrylic acid primer, a water-based polyurethane primer, a water-based inorganic silicate primer and a water-based inorganic zinc-enriched primer (single component); the double-component primers comprise a water-based epoxy primer, a water-based epoxy zinc-enriched primer, a water-based polyurethane acrylate primer and a water-based inorganic zinc-enriched primer; all the intermediate paints are double-component intermediate paints comprising a water-based epoxy mica iron intermediate paint and a water-based polyurethane acrylate intermediate paint; the finishing paints comprise single-component finishing paints and double-component finishing paints; the single-component finishing paints comprise a water-based acrylic acid finishing paint and a water-based polyurethane finishing paint; and the double-component finishing paints comprise a water-based polyurethane acrylate finishing paint. According to the invention, various environment-friendly requirements of the novel environment-friendly method to coating products are solved; simultaneously, the comprehensive properties of engineering machinery required by adopting the traditional oily coating are also optimized; and the coating cost is greatly reduced.

Description

technical field [0001] The invention relates to the field of paint production, in particular to the coating of a water-based paint applied to construction machinery products. Background technique [0002] Under the pressure of smog, the National People's Congress revised the Environmental Protection Law for the first time in 25 years. The revision of the "Environmental Protection Law" was passed, which increased the punishment of large polluters. The amendment clearly stipulates that polluting enterprises can be punished according to the original The amount is continuously punished on a daily basis. With the specific implementation of the revised Environmental Protection Law, the state has severely cracked down on various coating companies. Enterprises that have not carried out rectification according to the plan required by the national environmental protection department have been punished by means of rectification, punishment, and suspension of production. Since 2014, As...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D163/00C09D133/00C09D175/04C09D175/14C09D1/00B05D1/38

CPCC09D5/002B05D1/36C09D1/00C09D133/00C09D163/00C09D175/04C09D175/14

Inventor 任明华江拥

Owner 成都拜迪新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com