SIS-b-PEO hot-melt pressure-sensitive adhesive and preparation method thereof

A hot-melt pressure-sensitive adhesive, sis-b-peo technology, applied in adhesives, adhesive types, polyether adhesives, etc., can solve the problem of affecting the adhesion performance of hot-melt pressure-sensitive adhesives and weakening system compatibility And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] As a comparative test, the commercially available SIS was used to prepare SIS-based hot-melt pressure-sensitive adhesive, and the specific steps were as follows: 2 In an airtight container, 80-100 parts by weight of C5 petroleum resin, 10-30 parts by weight of mineral oil and 1.0-2.0 parts by weight of antioxidant tetrakis[β-(3,5-di-tert-butyl -4-Hydroxyphenyl)propionic acid]pentaerythritol ester melted at 120-150°C for 10-20 minutes, then added 50-70 parts by weight of SIS, melted and mixed at 140-180°C for 10-30 minutes, and melted directly Coating, the adhesion performance is tested by the national standard (GB / T4851-1998), and the adhesion performance results are shown in the attached table.

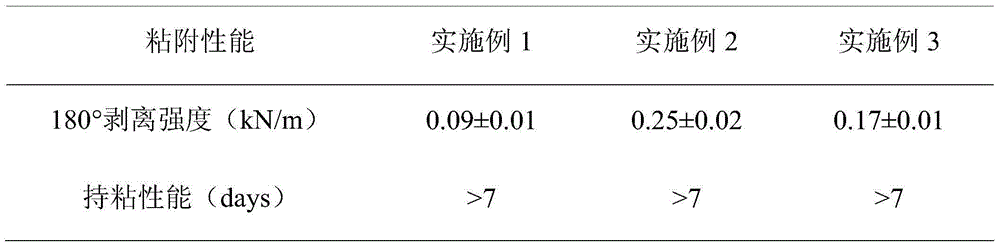

[0019] Attached Table Adhesion Properties of Hot Melt Pressure Sensitive Adhesives

[0020]

Embodiment 2

[0022] The preparation of SIS-b-PEO-based hot-melt pressure-sensitive adhesive, the specific steps are as follows: 2 In an airtight container, 80-100 parts by weight of C5 petroleum resin, 10-30 parts by weight of mineral oil and 1.0-2.0 parts by weight of antioxidant tetrakis[β-(3,5-di-tert-butyl -4-Hydroxyphenyl)propionic acid]pentaerythritol ester was melted and mixed at 120-150°C for 10-20 minutes, and then, 50-70 parts by weight of SIS-b-PEO with an ethylene oxide block content of 5wt% was added The copolymer is melt-mixed at 140-180°C for 10-30 minutes, and directly melt-coated. The adhesion performance is tested by the national standard (GB / T4851-1998). The adhesion performance results are shown in the attached table.

Embodiment 3

[0024] The preparation of SIS-b-PEO-based hot-melt pressure-sensitive adhesive, the specific steps are as follows: 2 In an airtight container, 80-100 parts by weight of C5 petroleum resin, 10-30 parts by weight of mineral oil and 1.0-2.0 parts by weight of antioxidant tetrakis[β-(3,5-di-tert-butyl -4-Hydroxyphenyl)propionic acid]pentaerythritol ester was melt-mixed at 120-150°C for 10-20 minutes, and then, 50-70 parts by weight of SIS-b-PEO with an ethylene oxide block content of 10wt% was added The copolymer is melt-mixed at 140-180°C for 10-30 minutes, and directly melt-coated. The adhesion performance is tested by the national standard (GB / T4851-1998). The adhesion performance results are shown in the attached table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com