Quantum dot/titanium dioxide composite nanodot array having visible-light response and preparation method of quantum dot/titanium dioxide composite nanodot array

A nano-dot array, titanium dioxide technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of cytotoxic genes, mutations, etc., and achieve a simple and easy-to-implement preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Add 62 μL of acetylacetone, 36 μL of deionized water, 100 μL of tetrabutyl titanate, and 0.4 g of polyvinylpyrrolidone to 5 mL of ethanol in sequence, stir at room temperature, and dilute to 10 mL in ethanol to obtain a precursor sol.

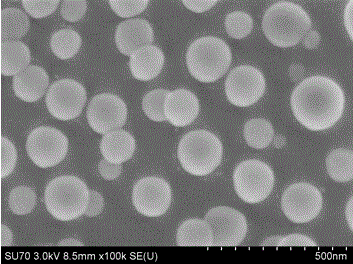

[0028] 2) Spin-coat 20 μL of the above precursor sol on the surface of quartz glass at a speed of 8000 rpm; place the sample in a muffle furnace, keep it at 500 °C for 1 h, take it out, rinse with deionized water, and dry to obtain titanium dioxide nanodots array (see figure 1 ). Its UV-Vis curve see Figure 4 Solid line, absorption limit at 401 nm.

Embodiment 2

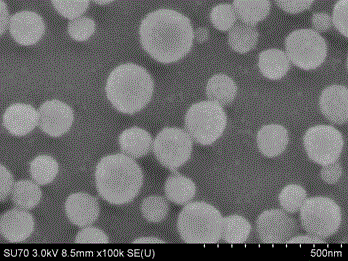

[0030] 1) Add 100 μL of acetylacetone, 1 μL of deionized water, 36 μL of C quantum dots with an excitation wavelength of 360 nm and a concentration of 5 μg / mL in 5 mL of ethanol, 680 μL of tetrabutyl titanate, 0.1 g of poly Vinylpyrrolidone was stirred at room temperature, and the volume was adjusted to 10 mL with ethanol to obtain a precursor sol.

[0031] 2) Spin-coat 15 μL of the above precursor sol on the surface of the silicon metal substrate at a speed of 6000 rpm; place the sample in a muffle furnace, keep it at 700 °C for 0.5 h, take it out, rinse it with deionized water, and dry it to obtain C quantum dot / titania composite nanodot array (see figure 2 ). The titanium dioxide nanodots range in size from 70 to 200 nm. Figure 4 The dashed line is the UV-Vis curve of the C quantum dot / titanium dioxide composite nanodot array with an excitation wavelength of 360 nm, and its absorption limit is 419 nm, compared with the titanium dioxide nanodot array without visible ligh...

Embodiment 3

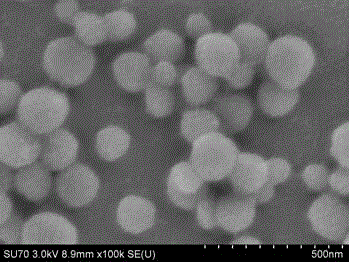

[0033] 1) Add 62 μL of acetylacetone, 100 μL of deionized water, 30 μL of C quantum dots with an excitation wavelength of 470 nm and a concentration of 5 μg / mL in 5 mL of ethanol, 1000 μL of tetrabutyl titanate, 0.5 g of poly Vinylpyrrolidone was stirred at room temperature, and the volume was adjusted to 10 mL with ethanol to obtain a precursor sol.

[0034] 2) Spin-coat 10 μL of the above precursor sol on the surface of the tantalum metal substrate at a speed of 10,000 rpm; place the sample in a muffle furnace, keep it at 400°C for 10 h, take it out, rinse it with deionized water, and dry it to obtain C quantum Dot / TiO2 composite nanodot array ( image 3 ). The titanium dioxide nanodots range in size from 70 to 200 nm. Figure 4 The dotted line is the UV-Vis curve of the C quantum dots / titanium dioxide composite nanodot array with an excitation wavelength of 470 nm, and its absorption limit is 431 nm, which is obviously red-shifted compared with the titanium dioxide nanodo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com