A dynamic polymer with hybrid cross-linked network and its application

A hybrid cross-linking and cross-linking network technology, applied in the field of intelligent polymers, can solve the problems of limited dynamics and restrictions of dynamic covalent bonds, achieve excellent tensile toughness and tear resistance, and improve tolerance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

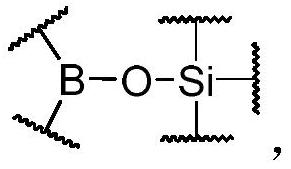

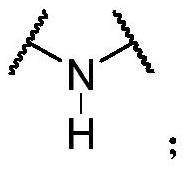

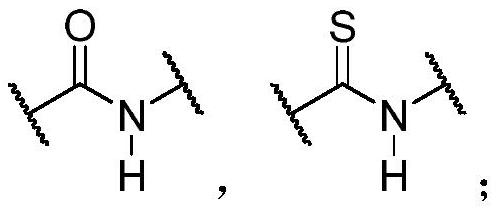

[0218] In the preparation process of dynamic polymers, for dynamic polymers with the first network structure (containing only one cross-linked network, and this cross-linked network contains organoboric acid silicon ester bond cross-links and supramolecular hydrogen bond cross-links) , which can be obtained by using at least one organoboron compound (I) and at least one silicon-containing compound (II) to participate in the reaction to generate organoborate silicon ester bonds and supramolecular hydrogen bonds for hybrid crosslinking; or use at least one compound ( III), or it participates in the reaction with at least one organoboron compound (I) and / or at least one silicon-containing compound (II) to generate organoboronic acid silicon ester bonds and supramolecular hydrogen bonds for hybrid crosslinking; or use at least one A compound (IV), or it participates in the reaction with at least one compound (V) to generate a common covalent bond to obtain hybrid crosslinking; wher...

Embodiment 1

[0314] A dynamic polymer with a single hybrid crosslinking network is prepared by using a macromolecular organoboron compound (I) and a small molecular silicon-containing compound (II).

[0315]

[0316] Add 20g of acrylamide-phenylboronic acid-urethane copolymer (a) in a three-necked flask (using methyl isocyanate and N-(2-hydroxyethyl) acrylamide as raw materials to prepare urethane mono Then use AIBN as an initiator to obtain acrylamide, 3-acrylamidophenylboronic acid, and carbamate monomers through RAFT free radical polymerization), 200ml deionized water / THF mixed solvent, heat to 50°C and stir After dissolving, slowly add 2.8g 1,1,3,3,5,5,7,7-octamethyl-1,7-tetrasiloxanediol (b), stir and mix for 30min, then add 2ml triethylamine , Continue to stir the reaction at 50°C for 2h. Then add 1.0g sodium dodecylbenzenesulfonate, 0.6g bentonite, 0.3g stearic acid, 0.3g oleic acid, then add 0.3g organic bentonite, 0.3g polydimethylsiloxane, 0.3g Dibutyltin dilaurate, 30mg lig...

Embodiment 2

[0318] A dynamic polymer with a single hybrid crosslinking network is prepared by using a macromolecular silicon-containing compound (II) and a small molecular organoboron compound (I).

[0319]

[0320]Take 7.5g of boric acid compound (b) (prepared by reacting 2-aminomethylphenylboronic acid and 1,6-hexamethylene diisocyanate) into a dry and clean reaction bottle, add 200ml of THF solvent, and heat to 60°C for Stir and dissolve, then add dropwise a small amount of 20% aqueous acetic acid solution, slowly add 30g of silane-modified polypropylene oxide copolymer (a) (with propylene glycol, propylene oxide, N-(2-ethylene oxide) under stirring base methyl) carbamate as raw material, and boron trifluoride ether as a catalyst, through cationic ring-opening polymerization to synthesize a propylene oxide copolymer with a carbamate group in the side group; -diphenylmethane diisocyanate, 3-aminopropyltrimethoxysilane reaction to obtain the final product) after stirring and mixing fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com