Oriented silicon steel strip with diagonal stripes, and production method thereof

A technology of oriented silicon steel and oblique stripes, which is applied in the field of oriented silicon steel strip and its production, can solve the problems of difficult rapid discharge of water vapor in the inner ring of the steel coil, high tension of the coating coil, and limited effect, so as to achieve the color difference of the bottom layer and the finished product Improvement of color difference in stripes and improvement of air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

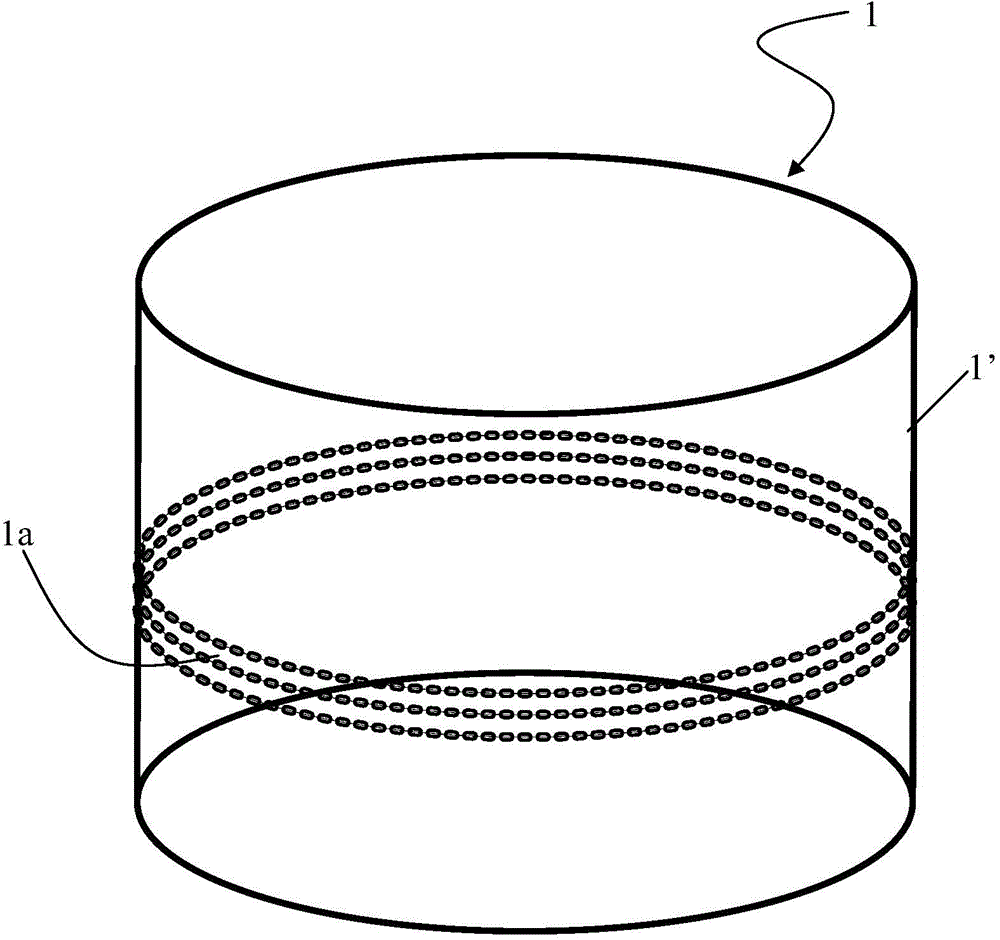

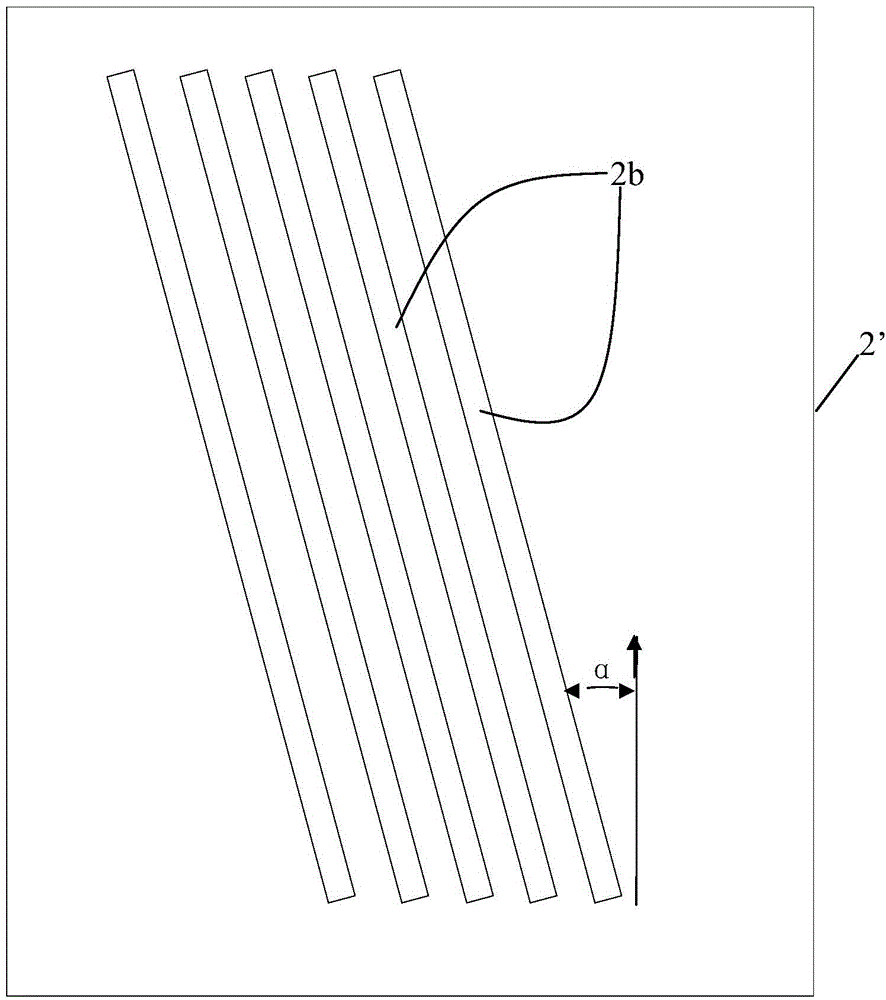

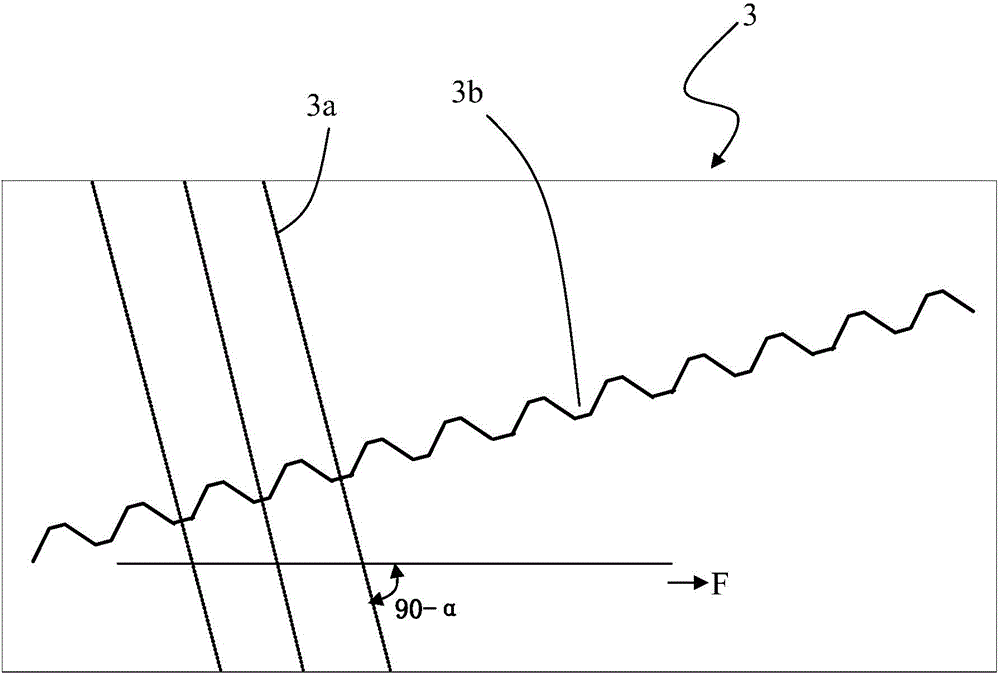

example 1

[0039] Obtain the oriented silicon steel decarburization annealed steel strip according to the conventional production method, select T-groove rolls, the groove depth h is 0.4mm, the groove top width m is 0.2mm, the groove bottom width n is 0.2mm, and the groove angle β is 45°. The groove pitch P is 1mm, and the center line of the groove depth is 45° to the length direction of the roll on the roll surface. , MgO coating with a width of 0.5-2mm and a depth difference of about 0.3mm, followed by high-temperature annealing, and finally an insulating coating and thermal stretch annealing to obtain the final oriented silicon steel product with diagonal stripes. The stripe angle on the finished surface is 43°≤α≤47°, and the stripe width is 1-3mm. 86 volumes were produced using the above method, and the quality of the final product was comparable to that of conventional products of the same period (with vertical stripes, such as figure 1 shown) were compared, and the results are sho...

example 2

[0044] Obtain oriented silicon steel decarburization annealed steel strip according to the conventional production method, select V-shaped groove roller to coat the release agent with MgO as the main component, then perform high temperature annealing, and finally apply insulating coating and thermal stretching annealing to obtain 2 kinds of angles The finished grain-oriented silicon steel products with oblique stripes have a stripe width of 1-3 mm, and 53 rolls and 86 rolls are produced respectively. One kind of finished product has a stripe angle of 47°≤α≤53°, and the other has a finished surface with a stripe angle of 13°≤α≤19°. The quality of the two products was compared, and the results are shown in 2:

[0045] Table 2

[0046]

[0047] It can be seen that the product quality corresponding to the priority angle of the invention example is better.

example 3

[0049] Obtain oriented silicon steel decarburization annealed steel strip according to the conventional production method, adopt T-shaped grooved rolls for selection, the groove depth centerline of the grooved rolls is 0° on the roll surface and the roll length direction, and coated with Al 2 o 3 The main component is the release agent, which forms on the steel strip a transverse Al with an angle of 90° to the strip length direction, a width of 0.5-2mm, and a height difference of 0.3mm. 2 o 3 Texture coating, high temperature annealing, and finally insulating coating and thermal stretching annealing to obtain a mirror-oriented silicon steel with a thickness of 0.26 mm. Final product quality compared with conventional mirror products in the same period (vertical Al 2 o 3 The quality of coating pattern) was compared, and the results are shown in Table 3:

[0050] table 3

[0051]

[0052] It can be seen that the magnetic performance corresponding to the inventive example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com