Iron and steel normal temperature rapid blackening solution and preparation method thereof

A normal temperature, steel technology, applied in the direction of metal material coating process, etc., can solve the problems of poor corrosion resistance, poor decoration, uneven color of the blackened film layer, etc., and achieve good synchronization, stable speed, and combination powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with specific examples.

[0036]

[0037] Examples 1-12 respectively provide the raw material composition of the rapid blackening solution of iron and steel at room temperature of the present invention, specifically as listed in Table 1 and Table 2, wherein the unit of each ingredient value is g / L, and the solution volume is 1L.

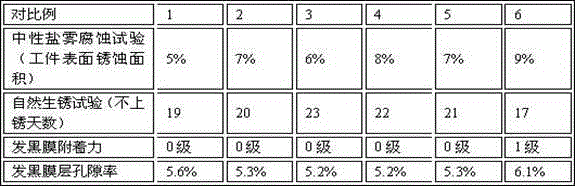

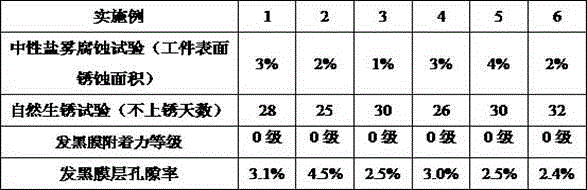

[0038] Table 1 embodiment 1-6 formula composition

[0039]

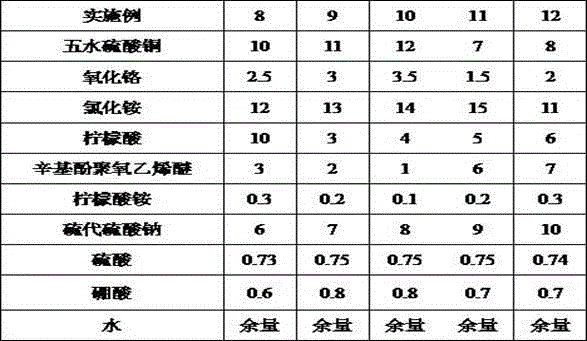

[0040] Table 2 Embodiment 7-12 formula composition

[0041]

[0042] The preparation method of above embodiment is as follows:

[0043] (1) Take two-thirds of the volume of water and add copper sulfate pentahydrate, sulfuric acid and ammonium chloride, and stir until completely dissolved;

[0044] (2) Add chromium oxide, stir until all dissolve, add boric acid, citric acid, ammonium citrate, sodium thiosulfate, stir until all dissolve;

[0045] (3) Add octylphenol polyoxyethylene ether, stir unti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com