Composite wave-resisting seepage-proof wall for coast flexible direct-current convertor station and transformer substation and construction method

A flexible direct current, composite anti-seepage technology, applied in the direction of coastline protection, pier, quay wall, etc., can solve the problems of long construction period, large occupied area, complex foundation treatment, etc., to achieve convenient and reliable construction, small occupied area, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

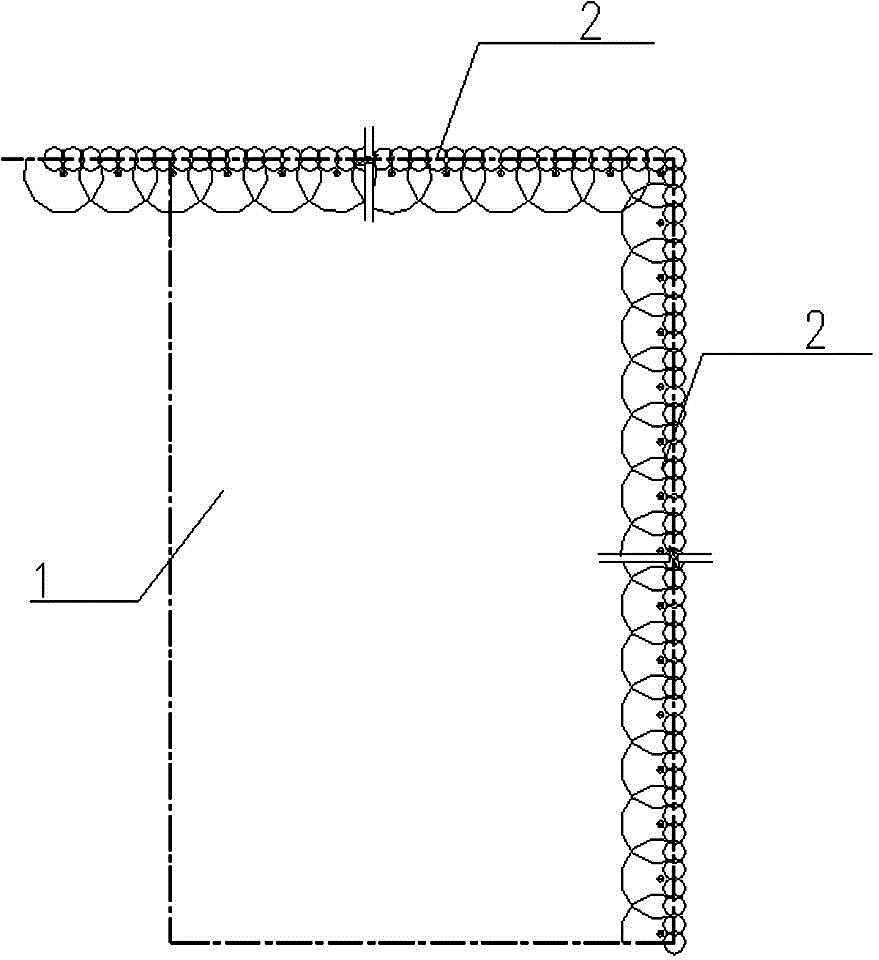

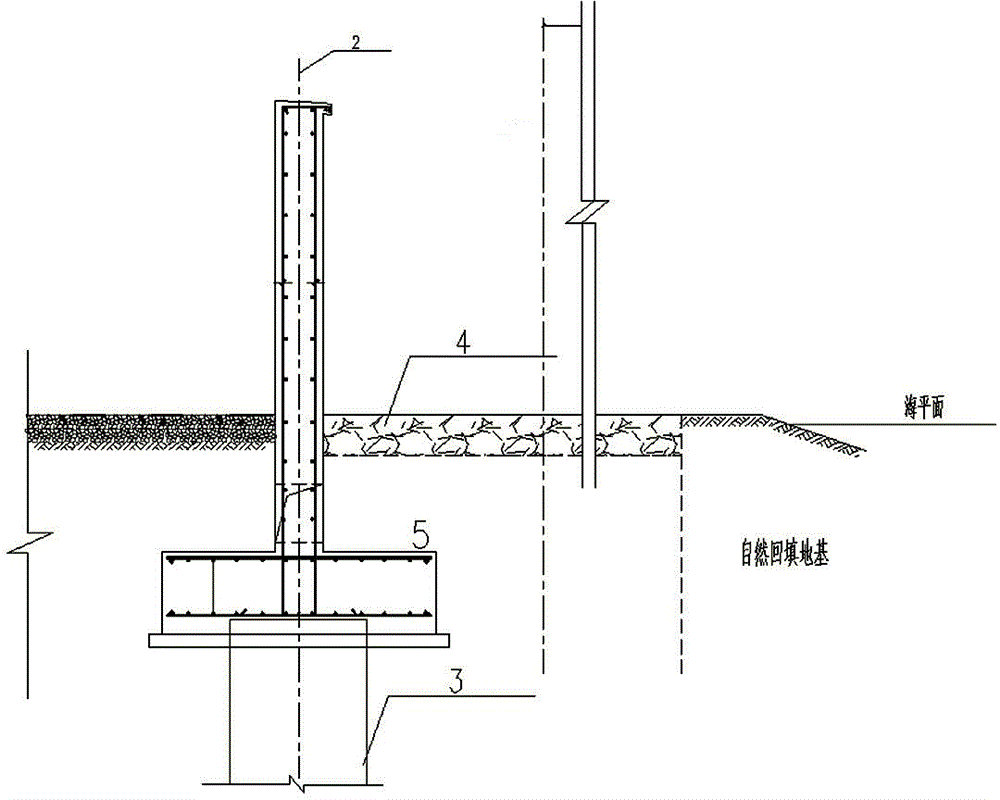

[0022] Embodiment: The present invention mainly builds the anti-wave wall and the surrounding wall together, and the gravity anti-wave wall doubles as the surrounding wall; the bottom or the outside of the anti-wave wall is provided with a composite anti-seepage body from the natural ground to the bedrock, and the method of the composite anti-seepage body is as follows: (1) Perform dynamic compaction or dynamic compaction replacement and compaction of easily scoured backfill soil and silt; (2) Close row-type cast-in-place piles for anti-scouring and anti-seepage on the basis of dynamic compaction; (3) After replacement Additional water-stop measures such as pre-filling thick grout and high-pressure grouting are adopted inside flow stations or substations. Through the above measures, a 3m wide anti-scouring and anti-seepage underground diaphragm wall with a width of about 3m is formed, which is mutually reinforcing and completely closed, to ensure the stability and reliability o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com