Pilot electromagnetic valve

A pilot-operated solenoid valve and electromagnet technology, applied in valve details, valve devices, valve operation/release devices, etc., can solve the problems of spontaneous combustion and explosion of electromagnetic coils, inability to seal, and softening of sealing rings, etc., to reduce quality , prevent explosion, improve the effect of reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0040] technical parameter:

[0041] Effective diameter: 10mm

[0042] Working pressure: 15MPa

[0043]Working medium: air, nitrogen (filter precision ≤40μm)

[0044] Working environment: seawater immersion depth 70m

[0045] Working voltage: DC24V

[0046] Working current: <1.5A

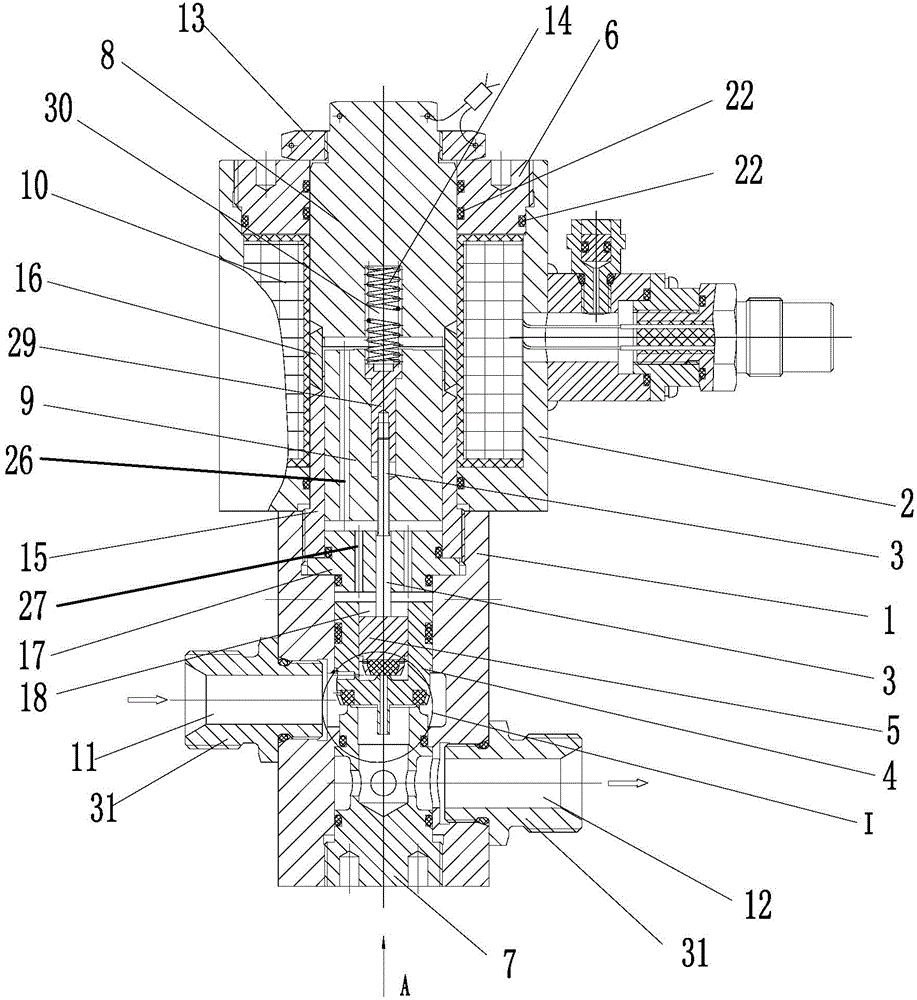

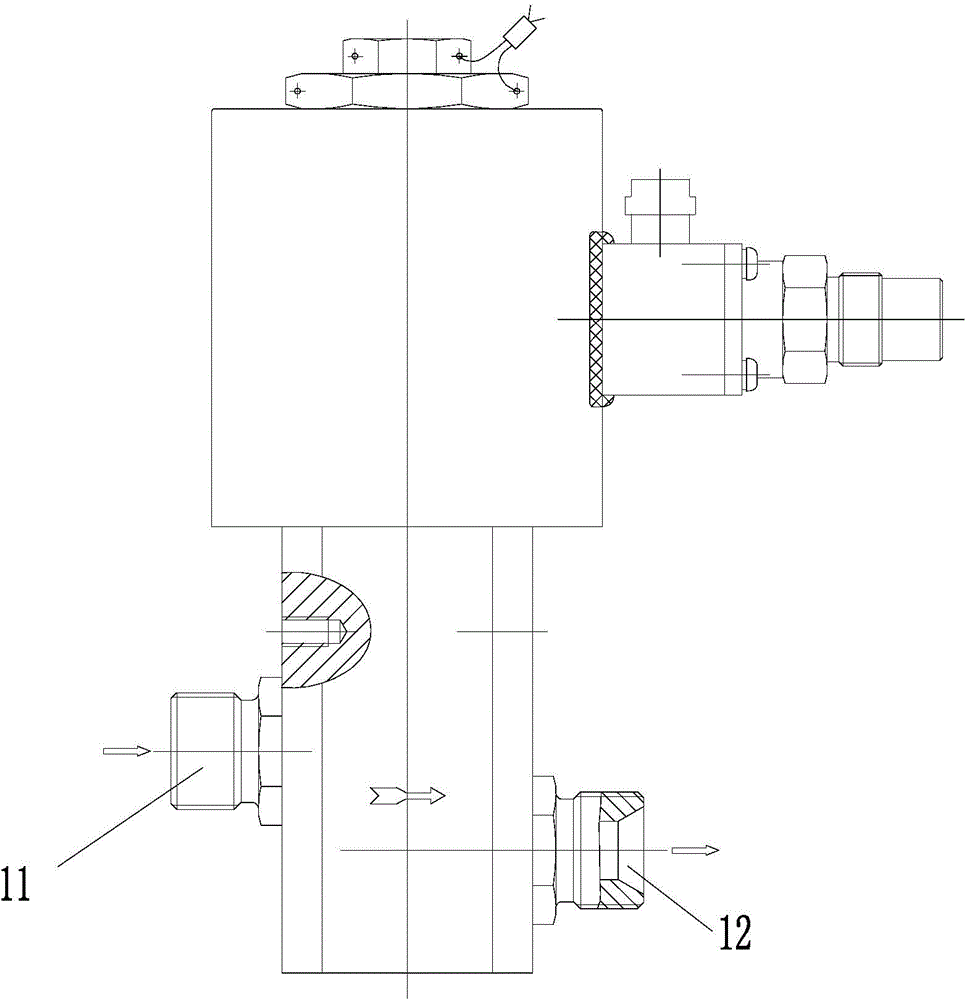

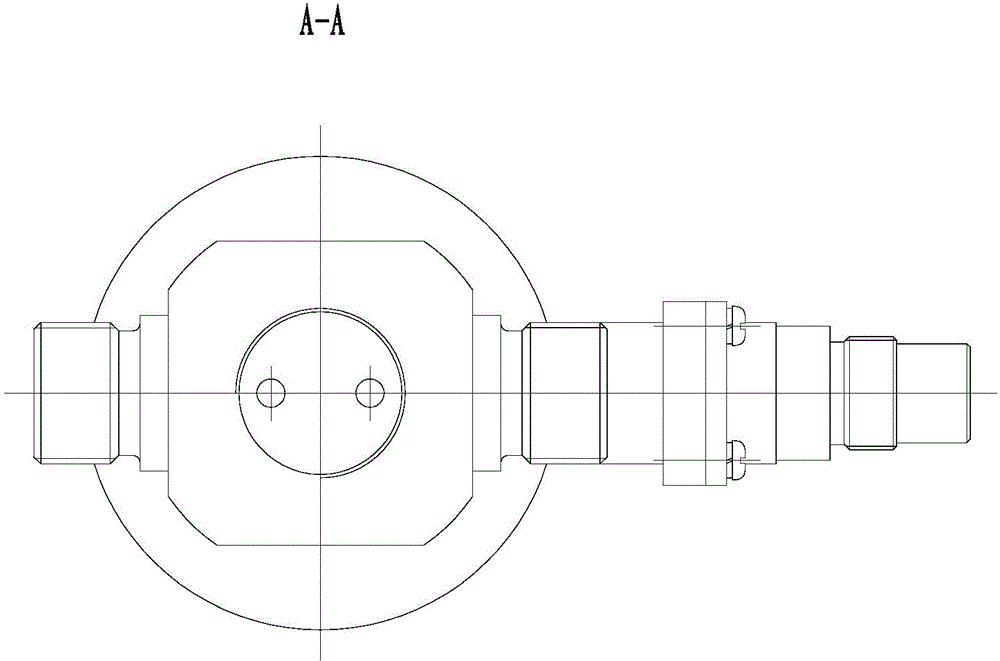

[0047] As shown in the figure, the present invention includes a valve body 1, an electromagnet casing 2, a valve stem 3, a main valve 4, an auxiliary valve 5, a yoke 6, a static iron core 8, a moving iron core 9, and an electromagnetic coil 10; the valve body 1 There are connected flow passages 11 and 12 inside, the electromagnet casing 2 is arranged on the top of the valve body 1, the yoke 6 is arranged on the upper end of the electromagnet casing 2, and the static iron core 8 is connected with the yoke 6; wherein, the main The valve 4 can be made of materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com