Novel efficient water supply heat recovery system for secondary reheating unit

A secondary reheating and reheating system technology, applied in the direction of feed water heaters, preheating, lighting and heating equipment, etc., can solve the problems of increasing exergy loss, damaging the energy saving effect of high parameters, and reducing the work of reheating, so as to improve High-pressure cylinder efficiency, reduce the risk of water shock, increase the effect of output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

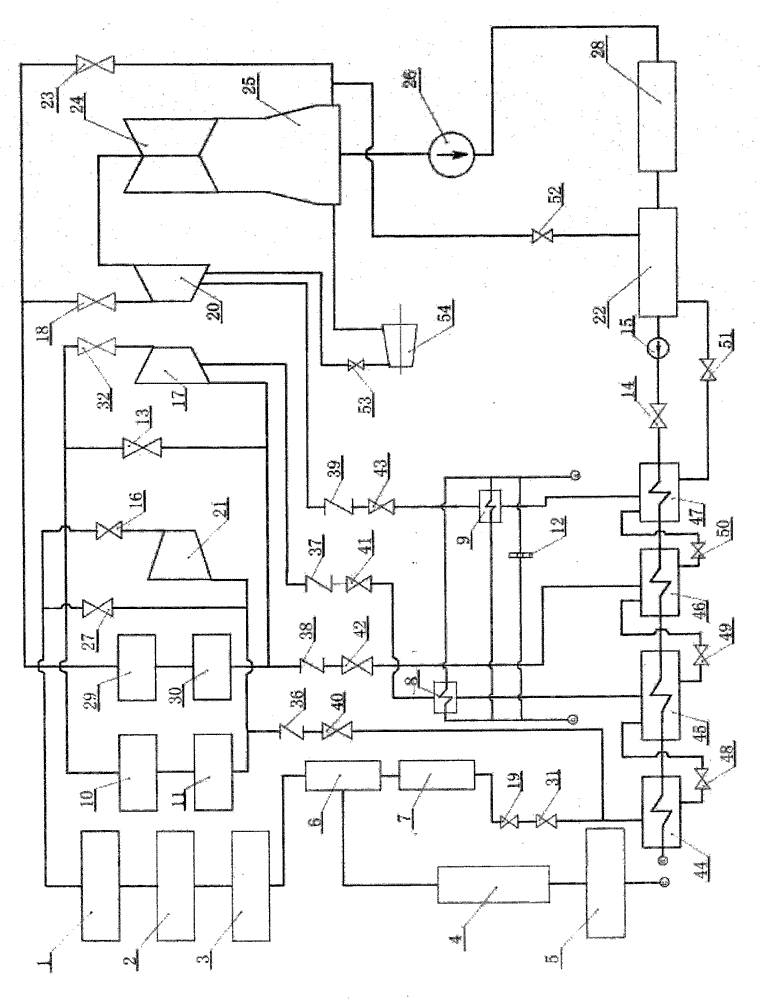

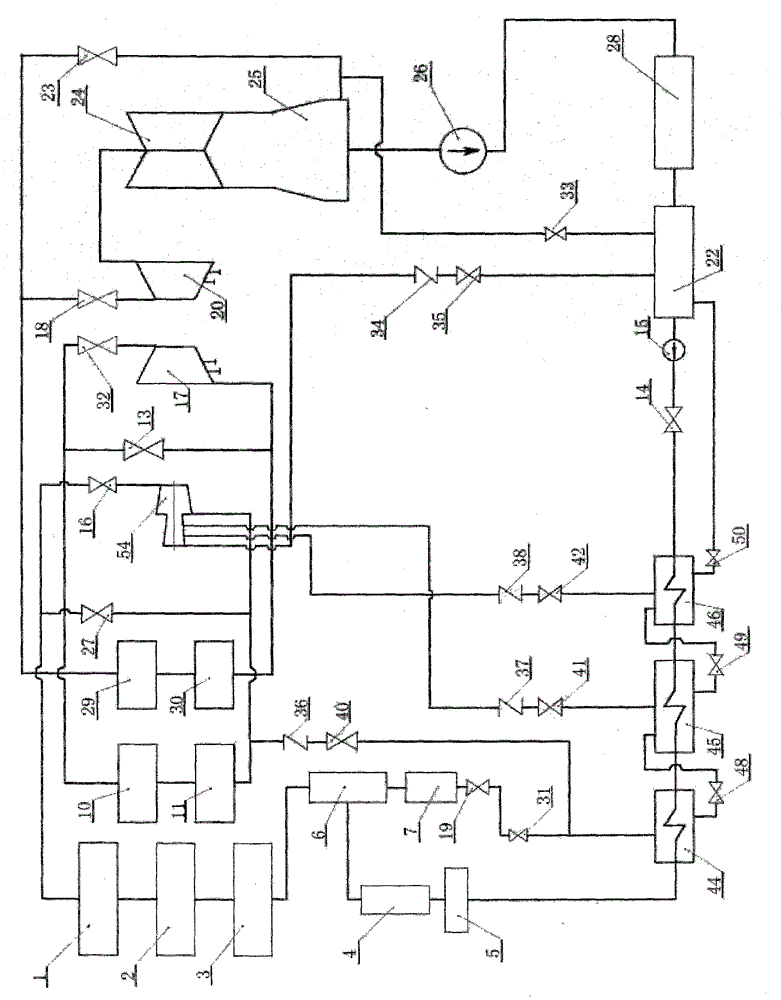

[0055] Combine now figure 2 , taking a 1000MW grade secondary reheat steam turbine unit with design values of main steam temperature / primary reheat steam temperature / secondary reheat steam temperature at 600°C / 620°C / 620°C as an example to illustrate the realization of the invention Preferred way. This type of double reheat steam turbine unit adopts 5 high-pressure heaters and 3 separate steam coolers. The high-pressure cylinder has an extra stage of extraction (steam extraction at the rear stage of the high-pressure cylinder) to send to the No. 3 high-pressure heater, and the high-pressure cylinder exhaust The steam is pumped into No. 4 high-pressure heater with 4 pumps, and the steam used by the deaerator and small machine is pumped with 6 pumps (steam extraction at the rear stage of the medium pressure cylinder).

[0056]A novel high-efficiency feed water recuperation system for secondary reheating units of the present invention includes: No. 1 high-fill steam inlet chec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com