Particle size and shape detection optical system capable of improving detection accuracy

A technology of particle size and optical system, which is applied in the field of optical sensors, can solve problems such as limited acceptance angle range, poor light uniformity in photosensitive area, and influence on shape detection accuracy, so as to increase acceptance angle range, improve beam uniformity, and improve detection accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

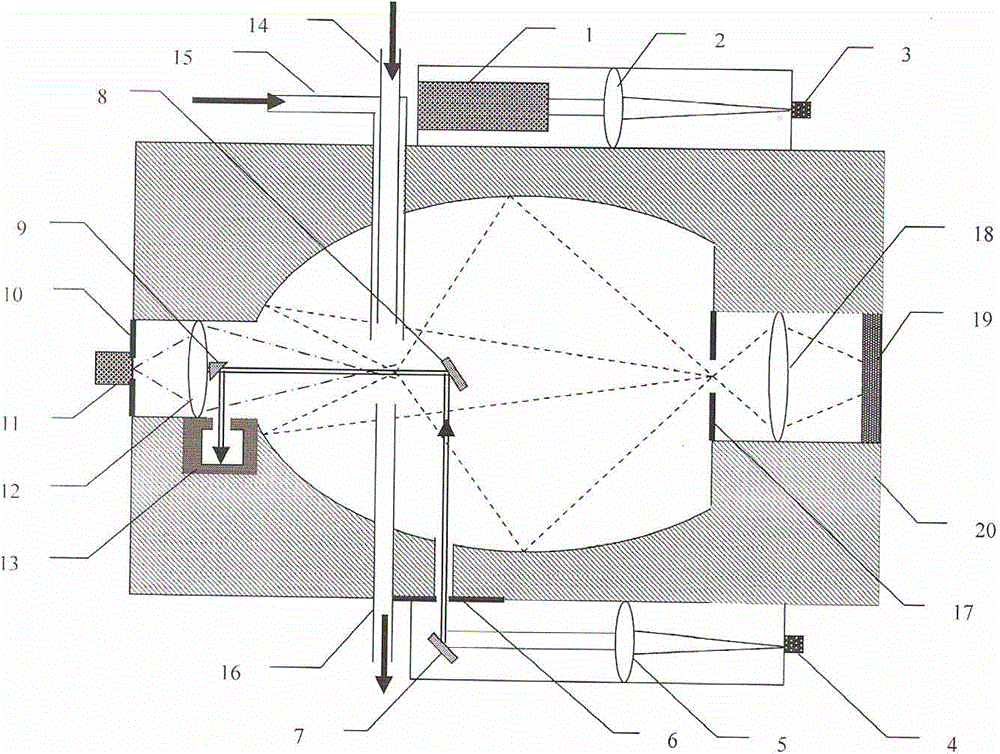

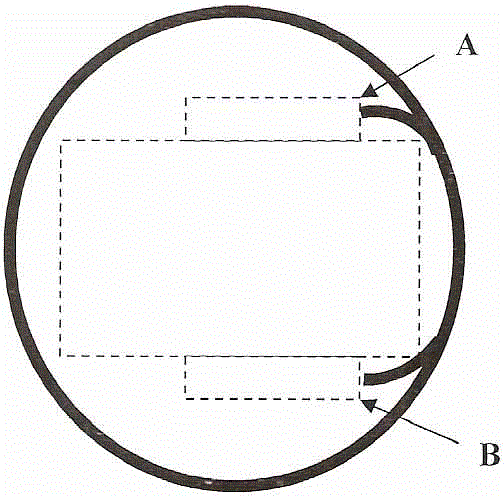

[0016] An optical system for detecting particle size and shape with a rotationally symmetrical elliptical cavity mirror, comprising a rotationally symmetrical elliptical cavity mirror 20, the elliptical cavity mirror is made of metal, and its inner surface is polished and coated with a reflective film. The laser is fixed on the outer frame, and after a certain optical path layout, it is collimated by the uniformity of the optical fiber to form a parallel beam with good uniformity, which is incident on the photosensitive area along the long axis of the rotationally symmetrical elliptical cavity mirror. The sample gas flow converges in the photosensitive area, that is, at a focal point of the rotationally symmetrical elliptical cavity mirror. The forward scattered light passes through the lens 12 and then passes through the first aperture 10 before being received by the photomultiplier tube 11. The incident beam from the original direction passes through the mirror 9 Inject into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com