Analysis method of acrylic resins

An acrylic resin and analysis method technology, applied in the direction of analysis materials, material separation, instruments, etc., can solve the problems of inability to meet the requirements of analysis, rough quantification, difficulty in simultaneous analysis of multiple components of homologs, etc., to save pretreatment costs, Simple and convenient operation, high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The accuracy of the method of the present invention is verified by a resin with a known monomer ratio, and a homemade methyl methacrylate and styrene copolymer with a ratio of 1:1 is obtained to obtain sample 1.

[0057] Take an appropriate amount of sample 1 for cracking, and obtain the cracking spectrum as Figure 5 .

[0058] Chromatographic conditions: the chromatographic column is DB-5MS chromatographic column;

[0059] Detector: ion source temperature: 230°C; interface temperature: 280°C

[0060] Programmed heating: 60~300℃

[0061] Cracking temperature 550°C

[0062] Drawn from the figure: the sample is a copolymer of methyl methacrylate and styrene, choose methyl methacrylate and styrene as the characteristic peak, and draw its integral ratio as 1.02:0.96;

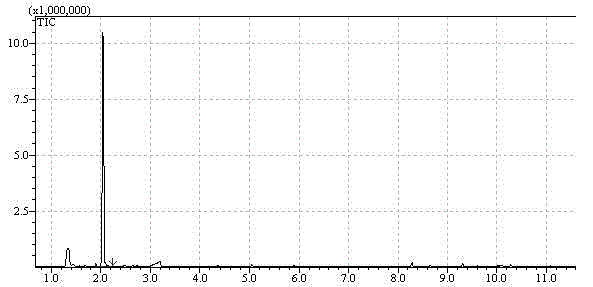

[0063] Get an appropriate amount of pure polymethyl methacrylate to crack, and obtain the cracking spectrum as figure 1 .

[0064] Chromatographic conditions: the chromatographic column is DB-5MS chro...

Embodiment 2

[0078] The accuracy of the method of the present invention is verified by a resin with a known monomer ratio, and a self-made butyl acrylate and styrene copolymer with a ratio of 4:1 is obtained to obtain sample 2.

[0079] Take an appropriate amount of sample 2 for cracking, and obtain the cracking spectrum as Image 6 .

[0080] Chromatographic conditions: the chromatographic column is DB-5MS chromatographic column;

[0081] Detector: ion source temperature: 230°C; interface temperature: 280°C

[0082] Programmed heating: 60~300℃

[0083] Cracking temperature 550°C

[0084] Drawn from the figure: the sample is a copolymer of butyl acrylate and styrene, and the peaks of butanol and styrene are selected as characteristic peaks, and the integral ratio is 1.0:0.9;

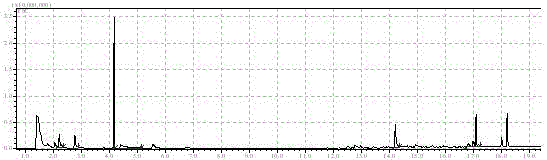

[0085] Take an appropriate amount of pure polybutyl acrylate for cracking, and obtain the cracking spectrum as image 3 .

[0086] Chromatographic conditions: the chromatographic column is DB-5MS chromatographi...

Embodiment 3

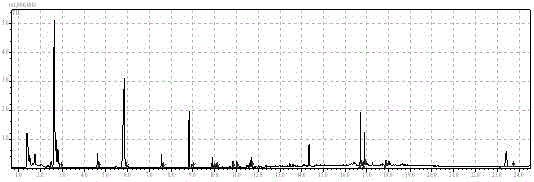

[0100] The accuracy of the method of the present invention is verified by a resin with a known monomer ratio, and a self-made copolymer of butyl acrylate, styrene and isooctyl acrylate, with a ratio of 2:3:5, to obtain sample 3.

[0101] Take an appropriate amount of sample 2 for cracking, and obtain the cracking spectrum as Figure 7 .

[0102] Chromatographic conditions: the chromatographic column is DB-5MS chromatographic column;

[0103] Detector: ion source temperature: 230°C; interface temperature: 280°C

[0104] Programmed heating: 60~300℃

[0105] Cracking temperature 550°C

[0106] It can be concluded from the figure that the sample is a copolymer of butyl acrylate, styrene and isooctyl acrylate, and the peaks of butanol, styrene and octanol are selected as the characteristic peaks, and the integral ratio is 0.47:2.88:9.41 ;

[0107] Take an appropriate amount of pure polybutyl acrylate for cracking, and obtain the cracking spectrum as image 3 .

[0108] Chrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com