Fan-out type packaging structure based on multiple layers of chips of organic substrate and packaging method

A multi-layer chip and packaging structure technology, applied in photovoltaic power generation, electrical components, climate sustainability, etc., can solve the problems of difficulty in applying large-scale mass production requirements, small application range, and low processing cost, and achieve improved heat dissipation Performance and electromagnetic shielding performance, wide application range, low CTE effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific drawings and embodiments.

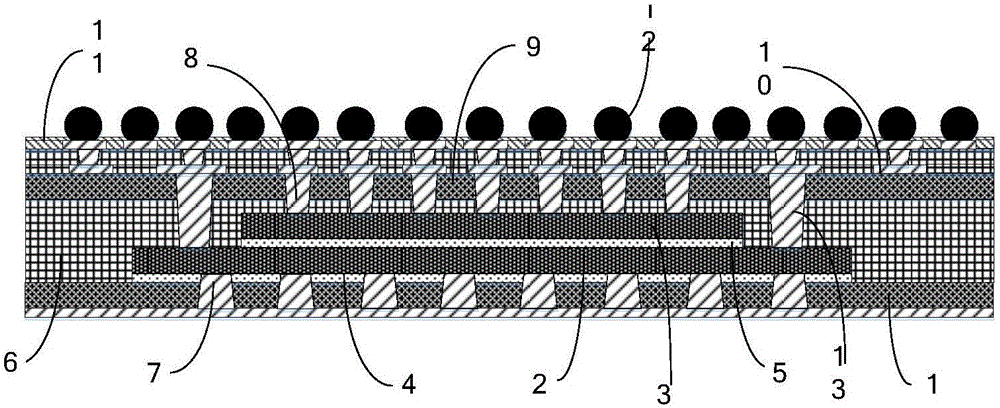

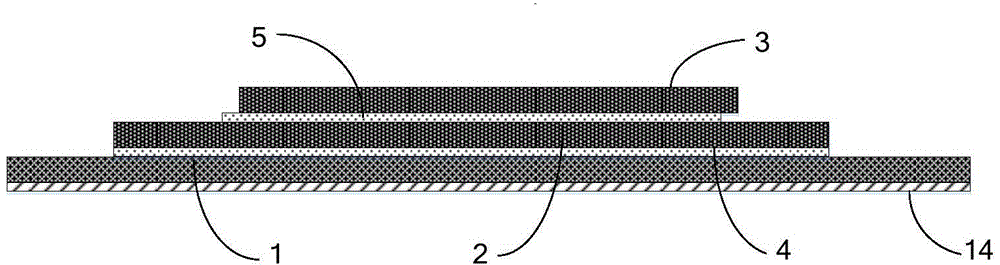

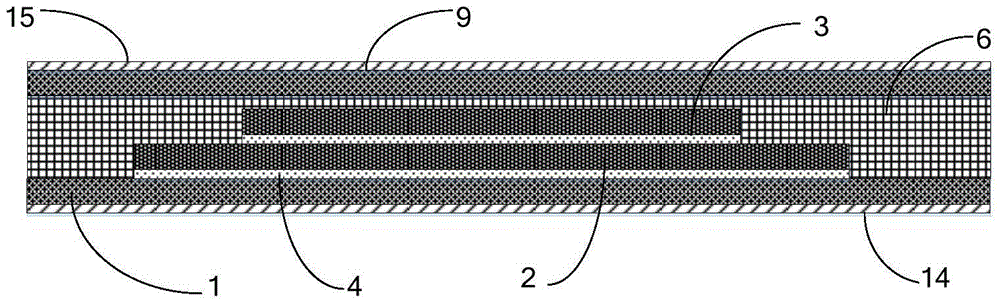

[0037] Such as figure 1 with Figure 8 As shown: in order to achieve a high degree of packaging integration, reduce packaging costs, and be suitable for large-scale mass production requirements, the present invention includes a lower organic core board 1, and multiple layers are laminated on the lower organic core board 1 through a dielectric layer 6 Chip, the multi-layer chip is supported in the lower organic chip 1 and is located in the dielectric layer 6; solder balls 12 for electrical connection with the multi-layer chip are arranged above the dielectric layer 6; heat dissipation columns are arranged in the lower organic core board 1 7. The heat dissipation column 7 penetrates the lower organic core board 1 and contacts the chips adjacent to the lower organic core board 1 .

[0038] Specifically, the heat dissipation column 7 may be a copper column, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com