Organic electroluminescent device and manufacturing method thereof

An electroluminescent device and electroluminescent technology, which are applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of total reflection loss, low light output performance, etc., so as to improve the injection capacity and improve the color purity of light. , the effect of improving hole injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

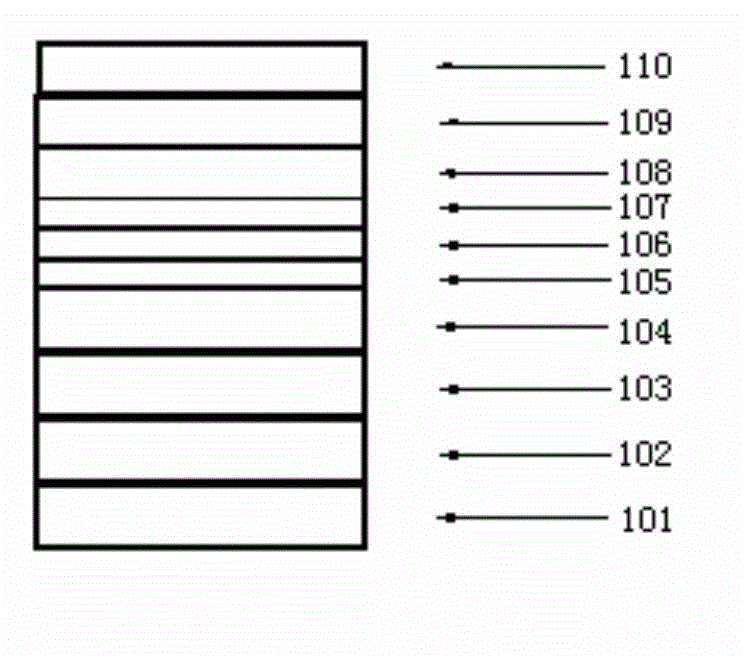

[0036] Such as figure 1 As shown, the organic electroluminescent device in this embodiment is a layered structure, and each layer is in turn:

[0037] Glass substrate 101, anode layer 102, metal doped layer 103, iron salt doped layer 104, hole injection layer 105, hole transport layer 106, light emitting layer 107, electron transport layer 108, electron injection layer 109 and cathode layer 110 . The metal doped layer 103 and the iron salt doped layer 104 constitute the heat dissipation layer. The structure of the organic electroluminescent device is glass substrate / ITO / Ag:BCzVBi / FeCl 3 :F4-TCNQ / MoO 3 / NPB / BCzVBi / TAZ / CsF / Ag, where the slash " / " indicates a layered structure, and the colon ":" indicates mutual doping. )

[0038] The above-mentioned organic electroluminescent device is prepared according to the following steps in sequence:

[0039] (1) Coating pretreatment

[0040] Take out the glass substrate 101 whose glass grade is N-LASF44, rinse it with distilled wat...

Embodiment 2

[0050] The organic electroluminescent device in this embodiment has a layered structure, and each layer is in turn: a glass substrate, an anode layer, a metal doped layer, an iron salt doped layer, a hole injection layer, a hole transport layer, a light emitting layer, Electron transport layer, electron injection layer and cathode layer.

[0051] The metal doped layer and the iron salt doped layer form the heat dissipation layer. The structure of the organic electroluminescent device is glass substrate / IZO / Al:ADN / FeBr 3 :1T-NATA / WO 3 / NPB / ADN / TAZ / CsN 3 / Al, where the slash " / " indicates a layered structure, and the colon ":" indicates mutual doping. The above-mentioned organic electroluminescent device is prepared according to the following steps in sequence:

[0052] (1) Coating pretreatment

[0053] Take out the glass substrate whose glass grade is N-LAF36, rinse it with distilled water and ethanol, and soak it in isopropanol for one night.

[0054] (2) Preparation of ...

Embodiment 3

[0062] The organic electroluminescent device in this embodiment is a layered structure, and each layer is sequentially:

[0063] Glass substrate, anode layer, metal doped layer, iron salt doped layer, hole injection layer, hole transport layer, light emitting layer, electron transport layer, electron injection layer and cathode layer. The metal doped layer and the iron salt doped layer form the heat dissipation layer. The structure of the organic electroluminescent device is glass substrate / AZO / Pt:DCJTB / Fe 2 S 3 :2T-NATA / V 2 o 5 / TCTA / DCJTB / Bphen / Cs 2 CO 3 / Au, where the slash " / " indicates a layered structure, and the colon ":" indicates mutual doping. The above-mentioned organic electroluminescent device is prepared according to the following steps in sequence:

[0064] (1) Coating pretreatment

[0065] Take out the glass substrate whose glass grade is N-LASF31A, rinse it with distilled water and ethanol, and soak it in isopropanol for one night.

[0066] (2) Prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com