Post-immersing liquid of circuit board electroless nickel immersion gold and post-immersing method

An electroless nickel-plated gold and circuit board technology, which is applied in liquid chemical plating, printed circuit, printed circuit manufacturing, etc., can solve problems such as missing plating, and achieve the effects of simple process, improved efficiency, and high yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

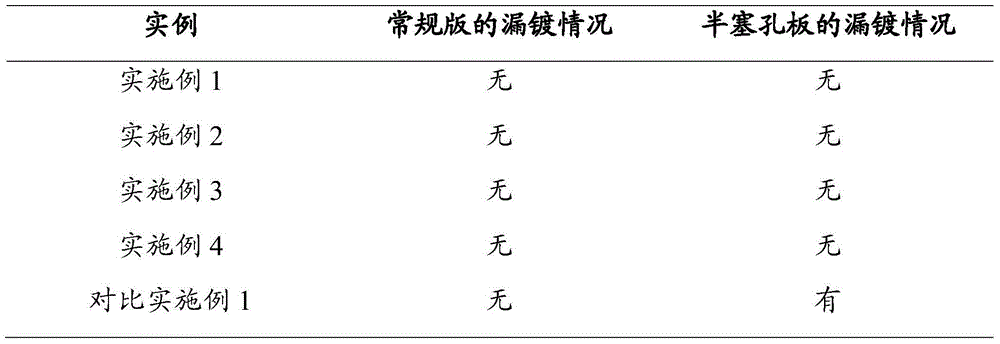

Examples

Embodiment 1

[0035] This embodiment provides a post-immersion solution for electroless nickel-gold plating on a circuit board, a post-dipping method for electroless nickel-gold plating on a circuit board, and a high-density printed circuit board. Wherein, the post-immersion solution of the electroless nickel-gold plating of the circuit board comprises the components of the following concentration content:

[0036] Sulfuric acid (98%): 3% (V / V)

[0037] Ascorbic acid: 10g / l

[0038] Gluconic acid: 30g / l

[0039] Deionized water: balance.

[0040] The post-dipping method of electroless nickel-plated gold on the circuit board comprises the following steps:

[0041] The circuit board after the activation treatment is placed in the post-immersion solution of the above-mentioned embodiment for post-dip treatment, wherein the process conditions of the post-dip treatment are: the temperature is 30° C., and the treatment time is 90 seconds.

[0042] The high-density printed circuit board is a h...

Embodiment 2

[0044] This embodiment provides a post-immersion solution for electroless nickel-gold plating on a circuit board, a post-dipping method for electroless nickel-gold plating on a circuit board, and a high-density printed circuit board. Wherein, the post-immersion solution of the electroless nickel-gold plating of the circuit board comprises the components of the following concentration content:

[0045] Sulfuric acid (98%): 3% (V / V)

[0046] Ascorbic acid: 10g / l

[0047] Malic acid: 20g / l

[0048] Gluconic acid: 20g / l

[0049] Deionized water: balance.

[0050] The post-dipping method of electroless nickel-plated gold on the circuit board comprises the following steps:

[0051] The circuit board after the activation treatment is placed in the post-immersion liquid of the above-mentioned embodiment for post-dip treatment, wherein the process conditions of the post-dip treatment are: the temperature is 20° C., and the treatment time is 120 seconds.

Embodiment 3

[0053] This embodiment provides a post-immersion solution for electroless nickel-gold plating on a circuit board, a post-dipping method for electroless nickel-gold plating on a circuit board, and a high-density printed circuit board. Wherein, the post-immersion solution of the electroless nickel-gold plating of the circuit board comprises the components of the following concentration content:

[0054] Sulfuric acid (98%): 3% (V / V)

[0055] Ascorbic acid: 10g / l

[0056] Gluconic acid: 10g / l

[0057] Deionized water: balance.

[0058] The post-dipping method of electroless nickel-plated gold on the circuit board comprises the following steps:

[0059] The circuit board after the activation treatment is placed in the post-immersion liquid of the above-mentioned embodiment for post-dip treatment, wherein the process conditions of the post-dip treatment are as follows: the temperature is 40° C., and the treatment time is 60 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com