light reflector

A light reflection, foam sheet technology, applied in optics, optical components, electronic equipment, etc., can solve the problems of inability to form bubbles, problems with thermoformability, problems in productivity, etc., and achieve small reflection differences and excellent thermoformability. , the effect of thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

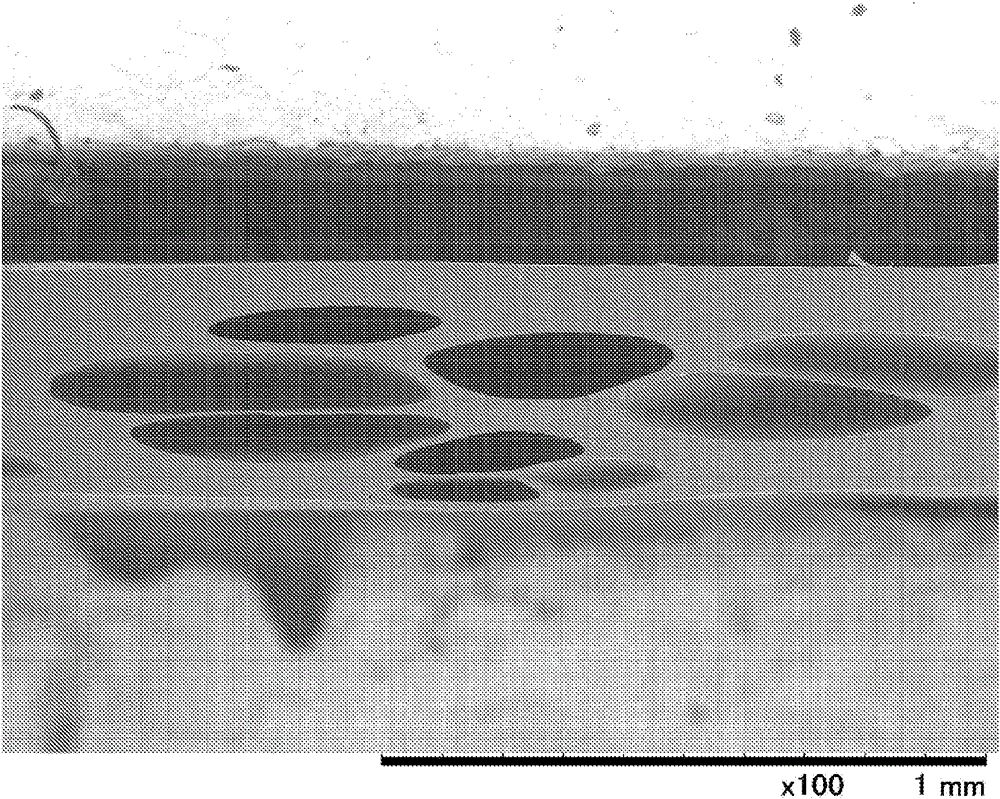

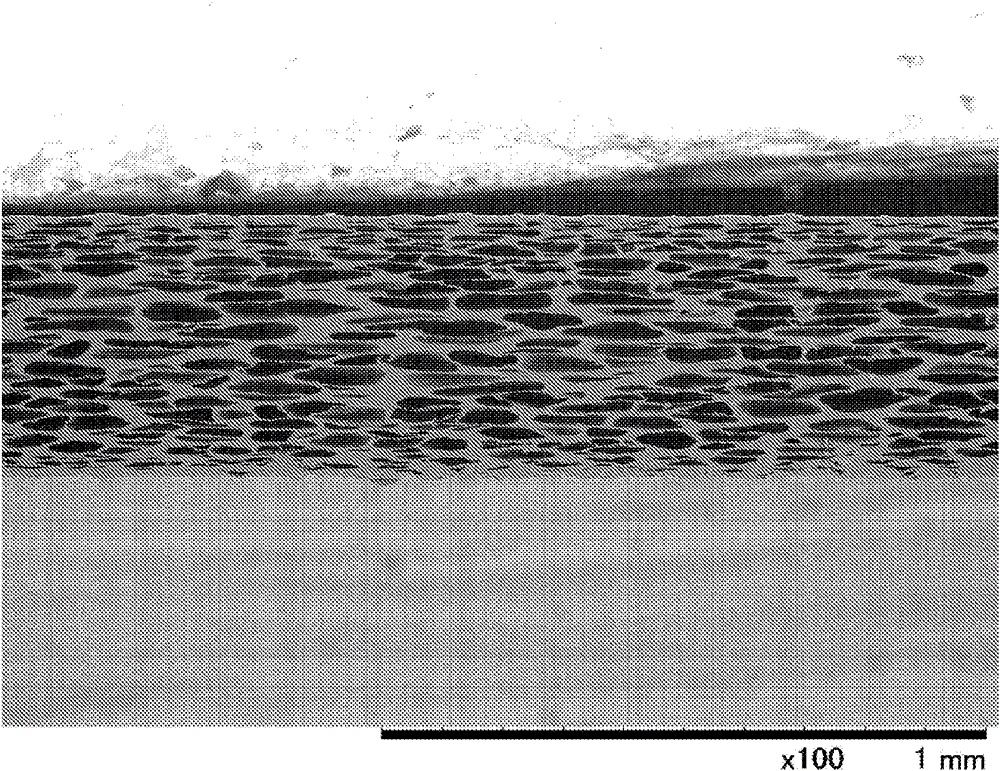

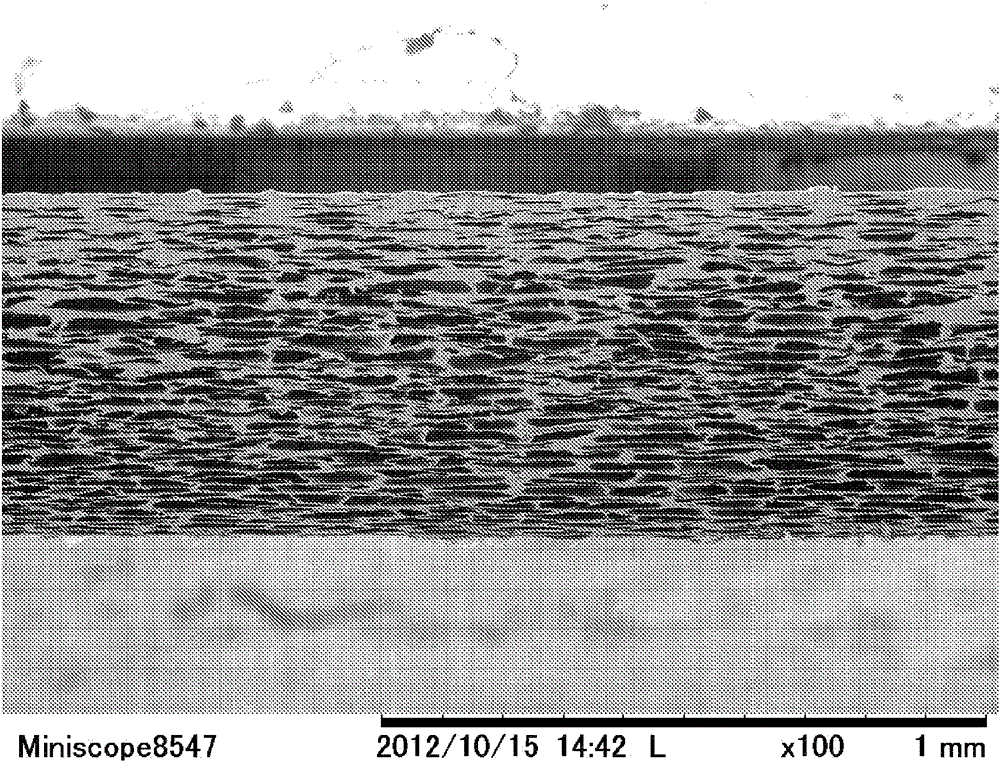

Image

Examples

Embodiment 1

[0111] The following examples and comparative examples illustrate the present invention in more detail, but the present invention is not limited to the following examples. The following raw materials were used in Examples and Comparative Examples.

[0112] (1) The polystyrene resin used in Examples 1-18 and Comparative Examples 1-5 is polystyrene resin GX154 (MFR1.6g / 10 minutes, hereinafter referred to as GPPS1) produced by PSJapan Company and PSJapan Company. Polystyrene resin 679 (MFR18g / 10min, hereinafter referred to as GPPS2) is a mixed resin mixed at a weight ratio of 50:50.

Embodiment 19

[0113] The polystyrene resin used in Example 19 is 100 parts by weight of methacrylic acid copolymer polystyrene resin G9001 (MFR1.7g / 10 minutes, hereinafter referred to as PSM1) produced by PSJapan Company and styrene produced by JSR Company It is a mixed resin composed of 8.4 parts by weight of elastomer TR2000 (MFR13g / 10 minutes, hereinafter referred to as SER1) and 20 parts by weight of 679 (MFR18g / 10 minutes, hereinafter referred to as GPPS2) produced by PSJapan.

Embodiment 20

[0114] The polystyrene resin used in Example 20 is 100 parts by weight of poly-α-methylstyrene resin R431 (MFR0.2g / 10 minutes, hereinafter referred to as PSα) produced by Asahi Kasei Chemical Co., Ltd. and JSR Co., Ltd. A mixed resin composed of 8.4 parts by weight of styrene-based elastomer TR2000 (MFR13g / 10 minutes, hereinafter referred to as SER1) and 20 parts by weight of polystyrene resin 679 (MFR18g / 10 minutes, hereinafter referred to as GPPS2) produced by PSJapan.

[0115] The measurement of the melt flow rate (MFR) was carried out under the conditions of a test temperature of 200° C. and a load of 5 kg in accordance with the condition H of JIS K7210.

[0116] (2) Titanium oxide having a rutile structure and an average particle diameter of 230 nm is used. A masterbatch comprising 70 wt% titanium oxide was formed using GPPS2. The obtained masterbatch is used in an amount to achieve the desired compounding amount of titanium oxide.

[0117] (3) Perfluorobutanesulfonate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com