Method and device for active molecule pre-oxidation to absorb NOx and SO2 in coal-fired flue gas

A technology for oxidative absorption and coal-burning flue gas, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, and can solve problems such as low efficiency, affecting removal efficiency, and high oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

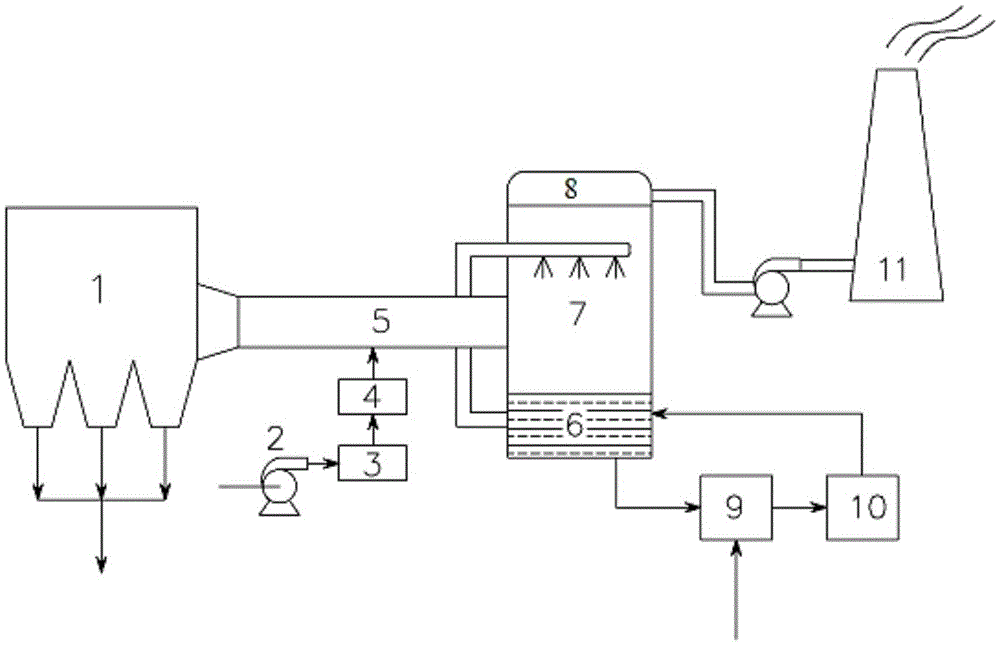

[0027] The specific implementation of the present invention will be described below with reference to the accompanying drawings.

[0028] The air from the fan 2 enters the ozone generating device 4 through the air drying and purifying device 3. The oxygen in the air is generated by the ozone generating device 4, and the ozone is sent to the space between the electrostatic precipitator at the outlet of the boiler 1 and the scrubber 7 In the low temperature (110~150℃) tail flue 5, ozone is sprayed in a porous grid to strengthen the mixing of ozone and flue gas; the flue gas components in the tail flue 5 are mixed with ozone, and NO in the flue gas is oxidized by ozone at the same time The amount of ozone injected is based on the concentration of nitrogen oxides in the flue gas and the removal efficiency requirements according to the molar ratio of ozone to nitrogen oxides. O 3 / NO is 1 to 1.5 for dynamic adjustment to ensure an oxidation reaction time of at least 0.5 seconds. The fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com