Reactor for gas-solid phase electrocatalytic reaction and method for eliminating vocs thereof

A catalytic reaction and reactor technology, applied in the field of gas-solid phase electrocatalytic reaction reactor, can solve the problem of eliminating indoor volatile organic pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

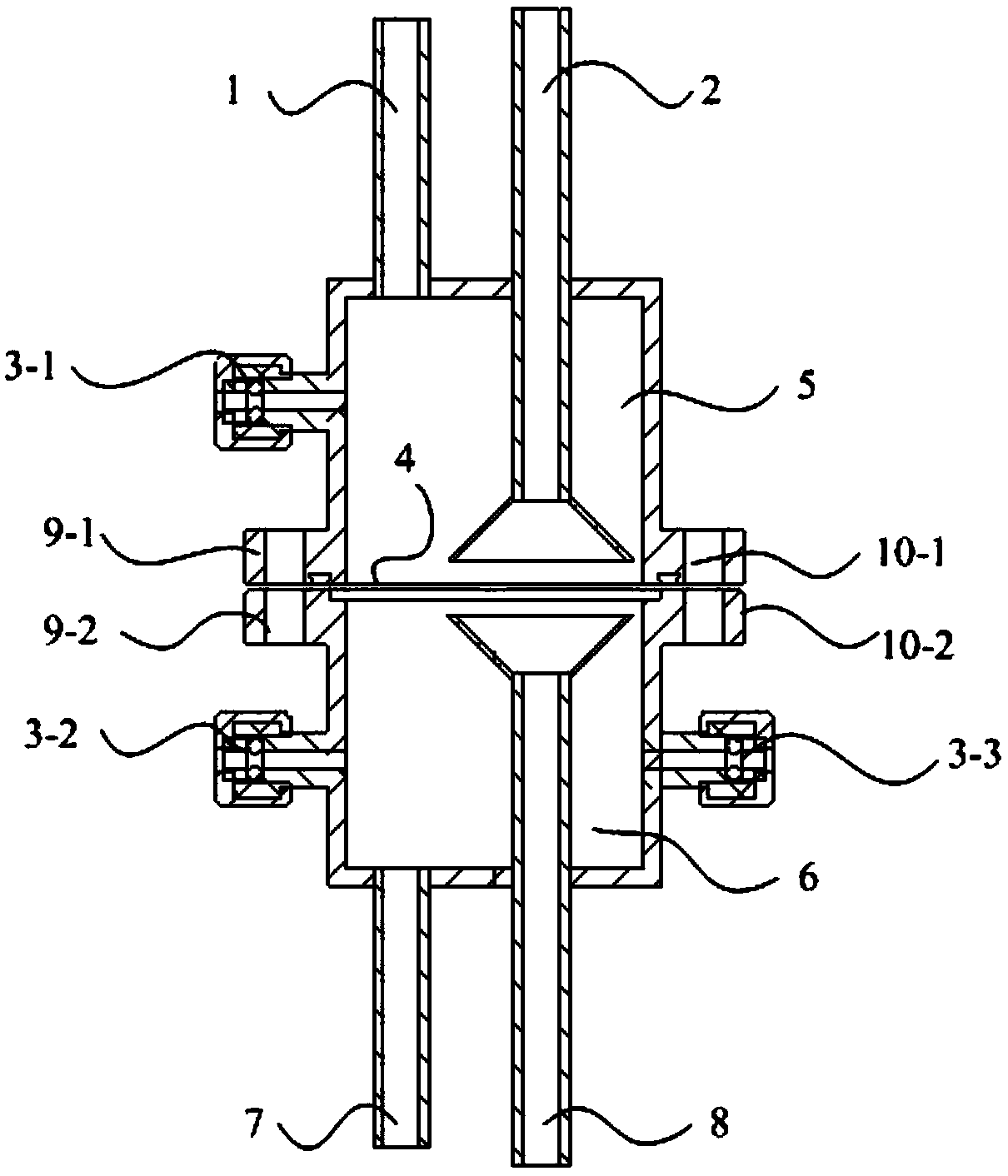

[0069] A reactor for gas-solid phase electrocatalytic reactions, such as figure 1 shown. The electrolytic cell comprises an anode gas chamber 5, a cathode gas chamber 6, an electrocatalytic anode, a diaphragm and an electrocatalytic cathode, and both the electrocatalytic anode and the electrocatalytic cathode are breathable; the diaphragm is airtight, and protons can pass through the diaphragm;

[0070] The diaphragm is placed between the electrocatalytic anode and the electrocatalytic cathode, and the three form a whole to form an integrated structure 4; the integrated structure 4 is formed by placing the electrocatalytic anode, diaphragm and electrocatalytic cathode under a pressure of 2-10 kg Pressed to get;

[0071] The anode gas chamber 5 and the cathode gas chamber 6 are independently cavities provided with through holes, the integrated structure 4 is placed between the through holes of the anode gas chamber 5 and the through holes of the cathode gas chamber 6, and the a...

Embodiment 2

[0098] A Ti / Sb-SnO 2 A preparation method comprising the steps of:

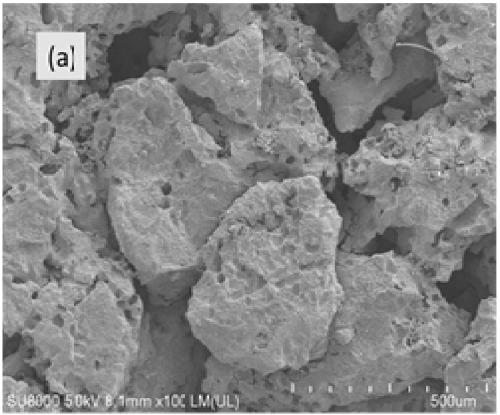

[0099] (1) Use foamed titanium as the base, first soak the base with 20wt% NaOH solution at 80°C for 10min, remove surface oil; then boil with 10wt% oxalic acid solution for 3h, the surface of the foamed titanium etched by oxalic acid is gray and pockmarked, as Figure 2a ; Ultrasonic cleaning of oxalic acid and titanium oxalate on the surface of the titanium substrate with distilled water to obtain a pretreated foam Ti substrate;

[0100] (2) Electroplating Sn and Sb on the pretreated foam Ti substrate, the plating solution is: 1M SnCl 4 , 0.2M SbCl 3 and 0.1MHNO 3 The ethylene glycol solution, the Pt sheet is the anode, and the current is 15mA cm -2 , the electroplating time is 60min; then baked at 500°C for 30min to obtain SnO on the surface 2 and Sb 2 o 3 Ti substrate;

[0101] (3) SnO on the surface 2 and Sb 2 o 3 Slurry on the Ti substrate, slurry composition: 0.5M SnCl 4 , 0.02M SbCl 3 , 0...

Embodiment 3

[0105] A Ti / Sb-SnO 2 The preparation method, described preparation method except that step (4) is roasting at 500 ℃ after repeating step (3) 10 times, all the other are the same as embodiment 1. 7.7mgcm generated on Ti substrate -2 SnO 2 -Sb 2 o 3 The oxide layer is Ti / Sb-SnO 2 electrode.

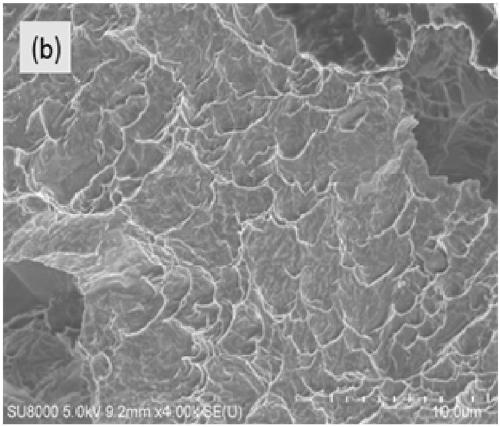

[0106] For the obtained Ti / Sb-SnO 2 The electrode was tested by XRD and SEM, and the results are: the obtained oxide layer completely covers the foamed Ti substrate, and Sb enters the SnO 2 Lattice induced SnO 2 The diffraction peak is red-shifted; the obtained oxide layer is dense and crack-free, and is composed of nanoparticles, doped with SnO 2 The particle size is 1-10nm, such as 2nm, 5nm, 7nm or 9nm. After analysis, the doping elements include F and Sb, the ratio of the total molar weight of F and Sb to the molar weight of Sn is 0.04; the molar ratio of Sb and F is 10:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com