Layered core-shell structure catalyst, preparation method and application thereof in low-temperature catalytic oxidation of toluene

A technology of core-shell structure and catalyst, which is applied in low-temperature catalytic oxidation of toluene, environmental pollutant degradation catalyst, layered core-shell structure catalyst, and preparation fields. It can solve the problems of failure to achieve better performance and achieve excellent reducibility, Large oxygen release and storage capacity, effect of toluene elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

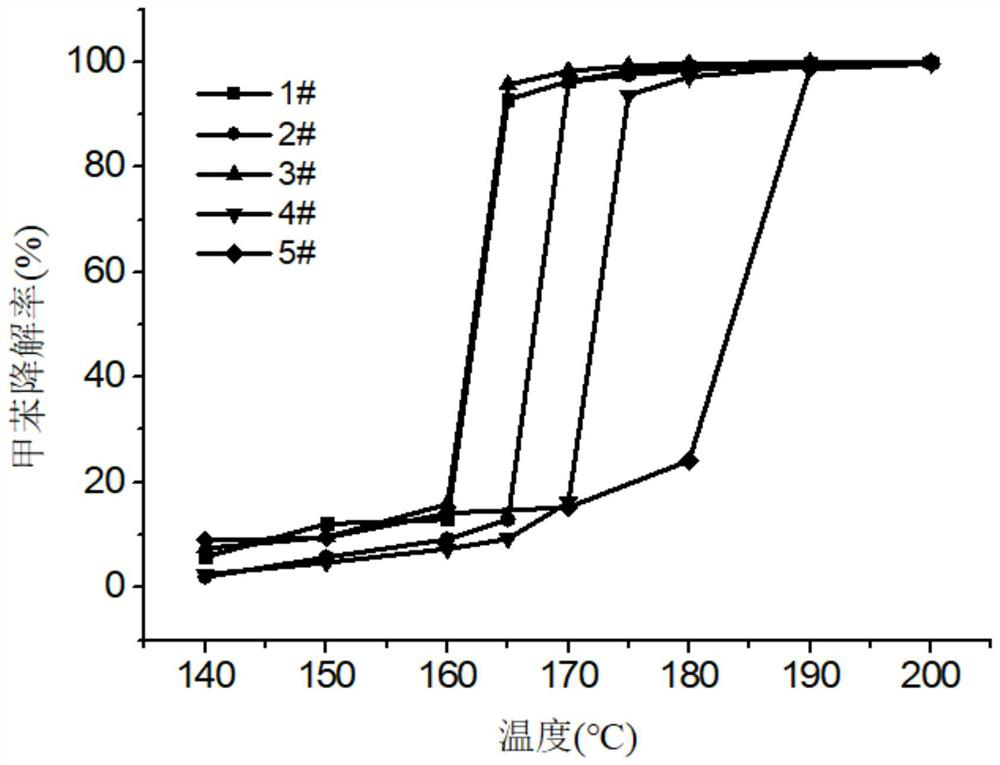

Embodiment 1

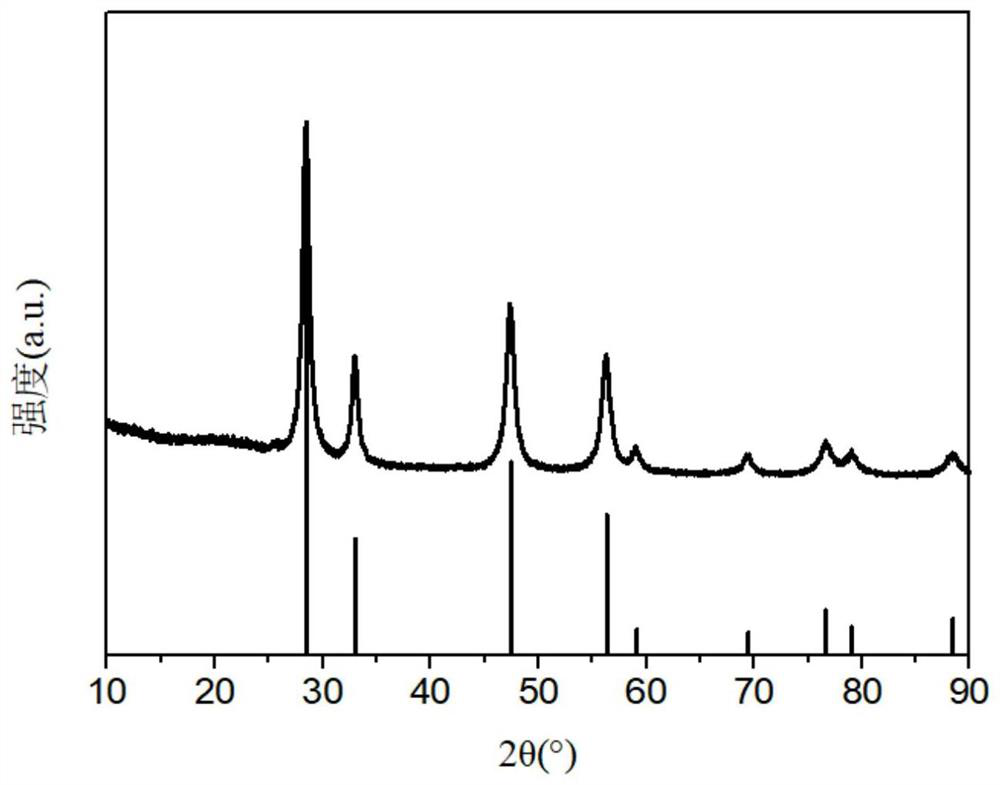

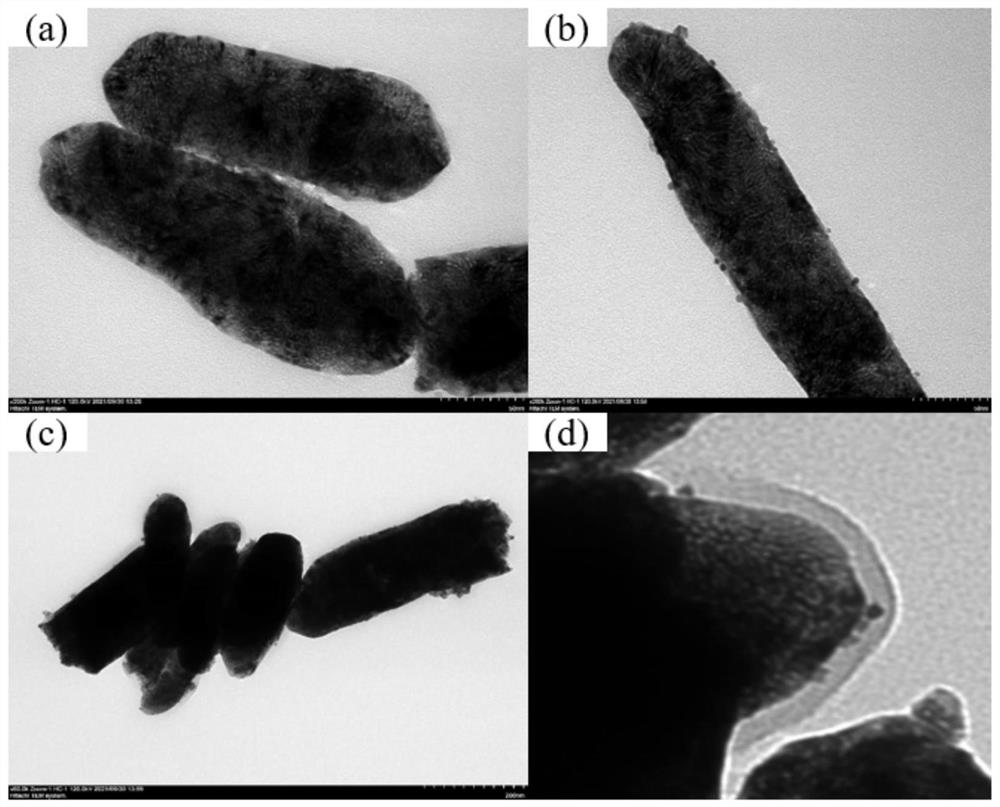

[0033] Step 1. Mesoporous CeO 2 Preparation of nanorods: 15 g of cerium nitrate was dissolved in 20 mL of distilled water, and 6.24 g of urea was dissolved in 20 mL of distilled water. The cerium nitrate solution and the urea solution were mixed and sealed in a high-pressure reactor, and placed in a blast drying oven at 120°C for 16 hours. After cooling to room temperature, the precipitate was obtained by centrifugation with a high-speed centrifuge, and then placed in a blast drying oven for drying treatment at 60°C for 12 hours. The obtained powder was placed in a tube furnace, and the temperature was raised to 400 °C at a heating rate of 2 °C / min and then kept for 4 h.

[0034] Step 2. Core-shell structure composite material mCeO 2 @MnO 2 Preparation: Take 300mg of prepared mesoporous CeO in step one 2 Nanorod powder was dissolved in 80mL of water, and ultrasonically dissolved; 1.2g of manganese nitrate solution was added, mixed evenly, and ultrasonically dispersed; the ...

Embodiment 2

[0042] Step 1. Mesoporous CeO 2 Preparation of nanorods: 16 g of cerium nitrate was dissolved in 20 mL of distilled water, and 6.4 g of urea was dissolved in 20 mL of distilled water. The cerium nitrate solution and the urea solution were mixed and sealed in a high-pressure reactor, and placed in a blast drying oven at 100°C for 18 hours. After cooling to room temperature, the precipitate was obtained by centrifugation with a high-speed centrifuge, and then placed in a blast drying oven at a temperature of 50° C. for 24 hours. The obtained powder was placed in a tube furnace, and the temperature was raised to 450 °C at a heating rate of 3 °C / min and then kept for 4 h.

[0043] Step 2. Core-shell structure composite material mCeO 2 @MnO 2 Preparation: Take 300mg of prepared mesoporous CeO in step one 2 Nanorod powder was dissolved in 80mL water and dissolved by ultrasonic; 0.3g of manganese nitrate solution was added, mixed evenly, and dispersed by ultrasonic; After centri...

Embodiment 3

[0046] Step 1. Mesoporous CeO 2 Preparation of nanorods: 14 g of cerium nitrate was dissolved in 20 mL of distilled water, and 6 g of urea was dissolved in 20 mL of distilled water. The cerium nitrate solution and the urea solution were mixed and sealed in a high-pressure reactor, and placed in a blast drying oven at 110°C for 17 hours. After cooling to room temperature, the precipitate was obtained by centrifugation with a high-speed centrifuge, and then placed in a blast drying oven at a temperature of 55° C. for 18 hours. The obtained powder was placed in a tube furnace, and the temperature was raised to 400 °C at a heating rate of 2.5 °C / min and then kept for 4 h.

[0047] Step 2. Core-shell structure composite material mCeO 2 @MnO 2 Preparation: Take 300mg of prepared mesoporous CeO in step one 2 Nanorod powder was dissolved in 80mL water and dissolved by ultrasonic; add 3g of manganese nitrate solution, mix evenly, and ultrasonically disperse; After centrifuging wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com