Dissimilar material brazing method of porous intermediate layer structure brazing seam

A technology of dissimilar materials and brazing methods, applied in the field of material welding, can solve the problems of weakening the mechanical properties of joints, joint damage, large residual stress of joints, etc., and achieve the effect of simple and feasible operation, reducing residual stress and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

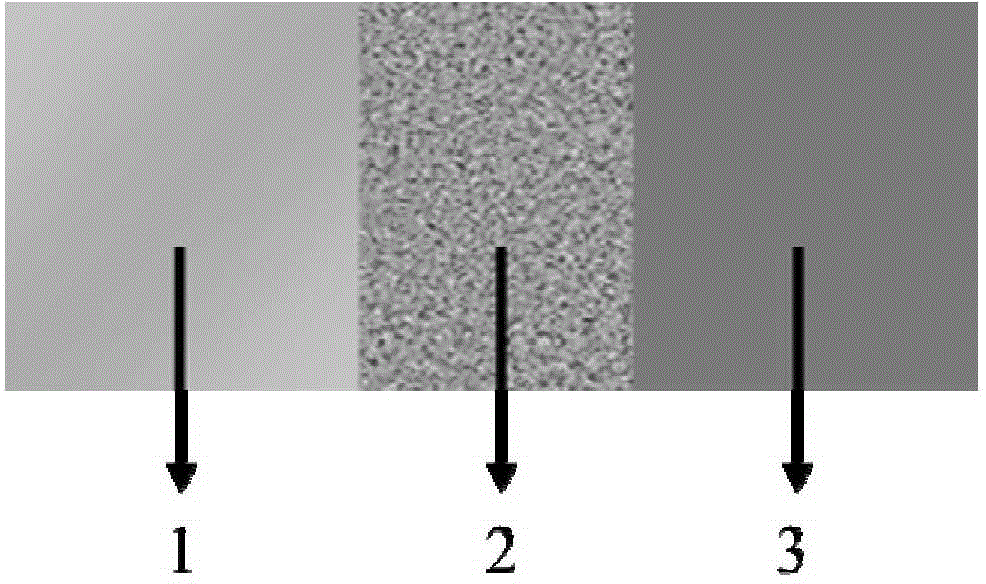

[0015] Specific implementation mode one: combine figure 1 Specifically illustrate the present embodiment, the dissimilar material brazing method of the porous intermediate layer structure brazing seam described in the present embodiment is specifically carried out according to the following steps:

[0016] 1. Polish the ceramic matrix composite material with sandpaper and wash it with acetone for 10 minutes to 20 minutes to obtain a ceramic matrix composite material with impurities removed from the surface; polish the metal material with sandpaper and wash it with acetone for 10 minutes to 20 minutes to obtain a metal material with impurities removed from the surface;

[0017] 2. Mix the nano-alumina template and the brazing material evenly to obtain the composite porous interlayer brazing filler metal, stack the ceramic matrix composite material with the impurity-removed surface and the metal material with the impurity-removed surface in sequence, and then place the composite ...

specific Embodiment approach 2

[0022] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the ceramic matrix composite material described in step 1 is SiC ceramics, SiO 2 -BN ceramic or SiO 2 ceramics. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the nano-alumina template described in step 2 has a pore diameter of 20 nm to 400 nm and a thickness of 20 μm to 60 μm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com