Cement-base self-leveling mortar

A self-leveling mortar and cement-based technology, applied in the field of building mortar additives, can solve the problems of poor mortar surface effect, affect project quality, insufficient early strength, etc., and achieve the effect of beautiful mortar surface, improved smoothness, and good construction effect.

Inactive Publication Date: 2015-04-01

张学健

View PDF4 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] (1) The early strength is low. The cement-based self-leveling mortar generally uses ordinary Portland cement as the cementing material, and the high water-cement ratio is used to obtain the fluidity of the construction, but the early strength is seriously insufficient

Affected the project put into use time and the quality of the project;

[0005] (2) After the mortar is hardened, it is easy to shrink, crack and other problems

The volume shrinkage of cement after hydration reaction, followed by the higher water-cement ratio of self-leveling mortar makes the shrinkage more serious in the later stage, which leads to cracks after the mortar hardens and seriously affects the quality of the project;

[0006] (3) The surface effect of the mortar is poor. Due to the imperfect mortar formula, it is easy to produce sanding, hollowing, peeling and other phenomena, which not only affects the appearance, but also endangers the quality of the project

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

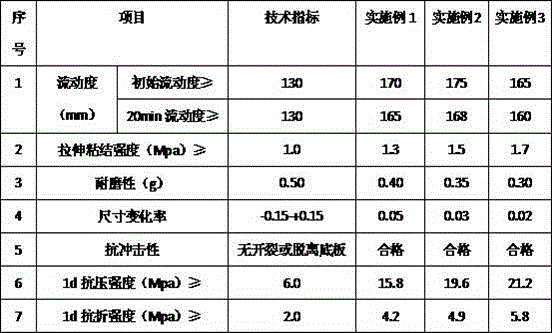

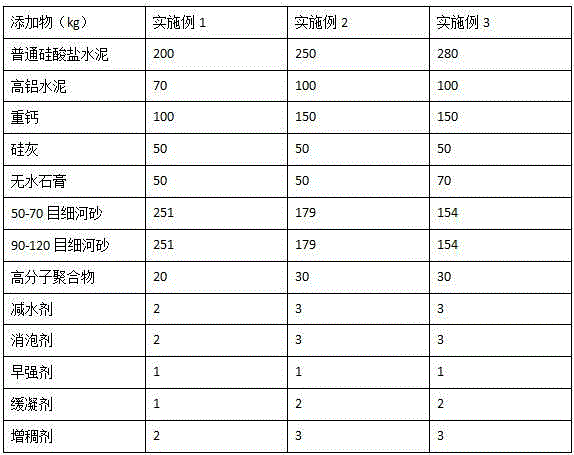

Embodiment 1--3

[0023]

[0024] The above-mentioned raw materials are screened, batched, fed, stirred and inspected. The cement-based self-leveling mortar of the present invention can be obtained.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a cement-base self-leveling mortar which is prepared from the following raw materials: 20-30% of ordinary Portland cement with the standard glue sand strength level of not lower than 42.5, 7-10% of high-alumina cement with the standard glue sand strength level of not lower than 62.5, 5-7% of anhydrous gypsum, 2-4% of high-molecular polymer, 0.2-0.4% of water reducing agent, 0.2-0.4% of defoaming agent, 0.1-0.2% of retarder, 0.1-0.2% of early-strength admixture, 0.2-0.3% of thickener and the balance of filler. Compared with other traditional cement self-leveling mortars, the cement-base self-leveling mortar disclosed by the invention has the advantages of favorable constructability, high early strength, no shrinkage in the later period, favorable wear resistance, beautiful mortar surface and the like.

Description

technical field [0001] The invention relates to the field of building mortar additives, in particular to a cement-based self-leveling mortar. Background technique [0002] Cement-based self-leveling mortar is a ground construction technology. It is a liquid substance mixed with multiple materials and water. After being poured into the ground, this liquid substance can flow according to the unevenness of the ground to automatically level the ground. And it will dry quickly, and the cured ground will form a smooth, flat and seamless new base layer. In addition to the leveling function, self-leveling can also play an important role in moisture resistance and antibacterial. This technology has been widely used in precision industries such as clean rooms, aseptic rooms, hospitals, and microelectronics manufacturing plants. [0003] The cement self-leveling mortar currently on the market mainly has the following problems: [0004] (1) The early strength is low. The cement-based ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/06C04B111/62

Inventor 张学健

Owner 张学健

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com