Firecracker paper papermaking waste water zero discharge recycling device

A paper-making wastewater and zero-discharge technology, which is applied in the direction of papermaking, textiles and papermaking, and wastewater treatment in processing, can solve the problems of insufficient sand removal effect and affecting the quality of sand removal wastewater reuse, and achieve a reasonable structure and practical, simplified system structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

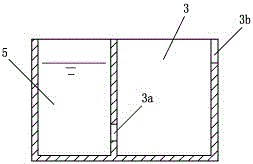

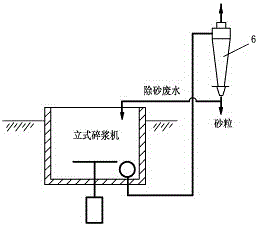

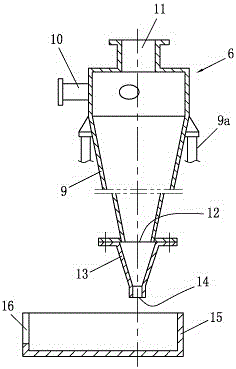

[0027] see figure 1 , figure 2 . The present invention includes:

[0028] The waste water conveying member 1, the outlet of the waste water conveying member 1 communicates with the pulper;

[0029] Screening the waste water pool 2, the outlet of the screening waste water pool communicates with the waste water conveying member 1;

[0030] A paper forming waste water tank 3, the outlet of the paper forming waste water tank is in communication with the waste water conveying member 1;

[0031] Squeeze the waste water pool 4, the outlet of the press waste water pool communicates with the waste water conveying member 1;

[0032] A pulp desander 6 is provided, and the pulping waste water is communicated with the pulper through the waste water outlet of the pulp desander 6 .

[0033] The cleaning waste water of blanket 7 enters press waste water pond 4, as figure 1 , figure 2 As shown, it can also enter the waste water delivery member 1 through the delivery member; a cleaning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com