Extruded asphalt pavement milling material crushing and screening device

A technology of crushing and screening, asphalt pavement, applied in the direction of road, road, road repair, etc., can solve the problems of difficult to guarantee the crushing quality, uneven particle size of old pavement materials, extensive pretreatment of milling materials, etc., and achieve convenient mixing ratio Design, high crushing and screening efficiency, and the effect of improving road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In the process of recycling the milling material, the pretreatment of the milling material is an important link, but there is no special device for crushing and screening the milling material in the prior art. The traditional method Manual crushing or overall crushing by mechanical crushing will undoubtedly increase the processing cost and time, and the processed milling material is still difficult to meet good use requirements. In response to this situation, the inventor team proposed this screening and crushing device:

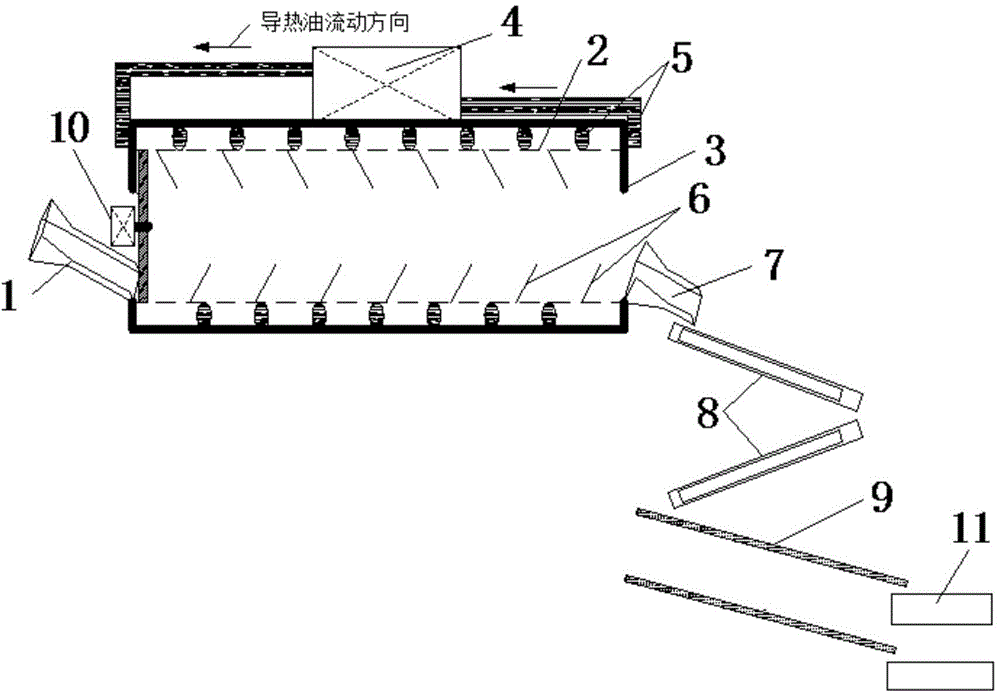

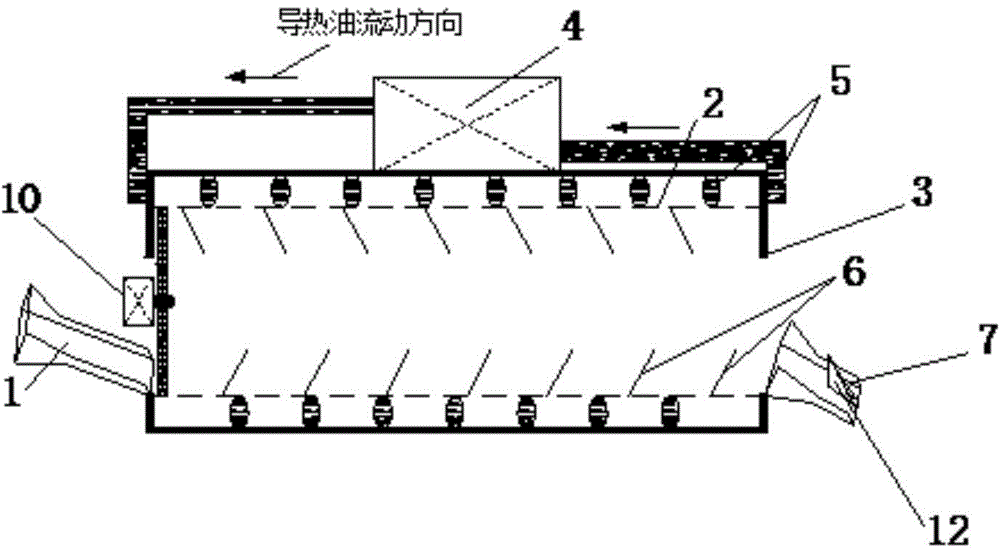

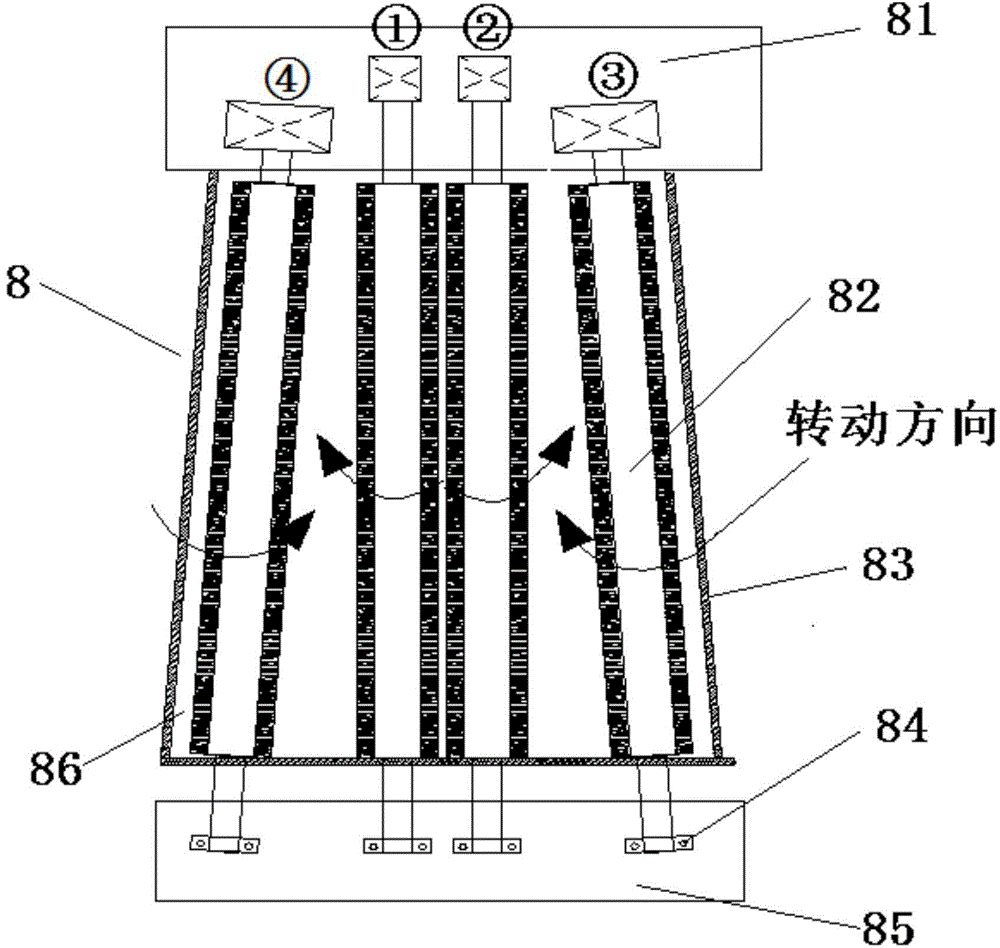

[0036] An extruded asphalt pavement milling material crushing and screening device, including a heating conveying system and a crushing and screening system;

[0037] The heating conveying system includes a drum 2, which rotates and transports the milling material from the feed chute 1 at the rear end of the drum 2 to the discharge chute 7 at the front end of the drum 2, and a heating milling material is arranged on the drum 2 the heating device;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com